Three Rows Stud Roll Forming Machine

Zhangjiagang City Saibo Science & Technology Co., Ltd.- Type:Rolling Machine

- Forging Forming Method:Mold Forging

- Power Source:Hydraulic Pressure

- Feature:High Efficiency

- Certification:ISO9001, CE

- Warranty:12 Months

Base Info

- Model NO.:Three rows

- Customized:Customized

- Advantage:Easy to Maintenance

- Condition:New

- Color:Blue and Yellow

- Transport Package:No Packing

- Specification:CE SGS

- Trademark:SAIBO

- Origin:Jiangsu China

- HS Code:84552210

- Production Capacity:300sets,Year

Description

Basic Info.

Model NO. Three rows Customized Customized Advantage Easy to Maintenance Condition New Color Blue and Yellow Transport Package No Packing Specification CE SGS Trademark SAIBO Origin Jiangsu China HS Code 84552210 Production Capacity 300sets/YearProduct Description

Three Rows Roll Forming MachineComposition of machine:

1. 3T manual decoiler

2. Feeding→roll forming→rectify device→post cutting

3. Output table

4. Hydraulic station

5. Control desk

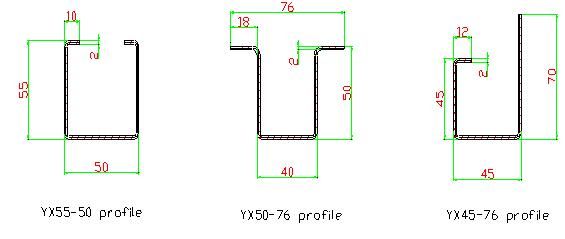

Profile, layout & production flow:

The structure of equipment

1: Uncoiler

- Width of feeding: 300mm

- Capability: 3Ton

- Range of expand(by manual): 420mm-510mm

- Mode of expand &fight: inner expand &fight by manual

- Way of feeding: manual

2: Feeding→roll forming→rectify→post cutting

- Feeding

- Armed adjustable center of the forming rollers and of sufficient length to prevent lateral movement of the strip on its entry to flattener.

- Entrance table-guide: adjustable

- Forming Section

- Machine Voltage, Frequency, Phase: 380 V, 50 Hz, 3Phase

- Roll station:11stations +1 station of rectify

- Roller material:SAE1045, hardness and chrome plated surface

- Shaft diameter: ¢56mm material: SAE1045

- Machine roll forming speed: 0-15m/min

- Transmission: by chain

- Rectify device:

- One station after roll forming,

- Function: for revise the end product up and down/ left and right to straightness

- Roller material: Roller material:SAE1045, hardness and chrome plated surface

- Adjust by hand wheel

- Post cutting system

- Machine adopt hydraulic cutting system, When cutting the machine will stop, after cutting will start the motion automatically.

- Hydraulic power: 3KW