Water Proof Metal Rolling Machine

Hangzhou Zhongyuan Machinery Factory- Type:Cold Roll Forming

- Forging Forming Method:Cold Roll Forming

- Power Source:Electric

- Feature:High Efficiency

- Certification:ISO9001, CE

- Warranty:12 Months

Base Info

- Model NO.:Metal Rolling Machine

- Customized:Customized

- Advantage:Easy to Maintenance

- Condition:New

- Quality Warranty:First Year Free, Lifetime Services

- Cutter Material:Cr12 Mould Steel Being Quenched Treatment

- Controlling System:Mitsubishi PLC & Converter

- Certificate:CE

- Quality System:ISO9001

- Main Motor:7.5kw

- Operation Language:English or as Per Client`S Required

- Rollers Material:No.45 Forged Steel, Plated with Hard Chrom

- Cutting Style:Cut to Length

- Machine Type:Water Proof Metal Roll Forming Machine

- Transport Package:40gp Container for One Machine

- Specification:CE SGS BV ISO

- Trademark:zhongyuan

- Origin:China

- HS Code:84552210

- Production Capacity:20sets,Month

Description

Water Proof Metal Rolling MachineItem Specification

Raw Material Type Pre-painted steel coil & galvanized coils Thickness(mm) 0.3-0.7 Yield strength(mpa) 235-550 Roller material 45# steel , coated with Chrome Shaft for rollers Solid shaft with 72mm,processed with cylindrical grinder Forming speed(m/min) About 20-25 Output speed(m/min) About 12 for 6m length sheet Speed adjusting mode Mitsubishi frequency transformer Roller drive Decelerating motor + Chain drive Cutting mode Hydraulic cutting Cutter material Cr12 mould steel Length measurement Nemicon Encoder Control mode Mitsubishi PLC Operating mode Button + Mitsubishi Touch screen Main motor power(kw) 7.5KW Total power(kw) 9.9 KW

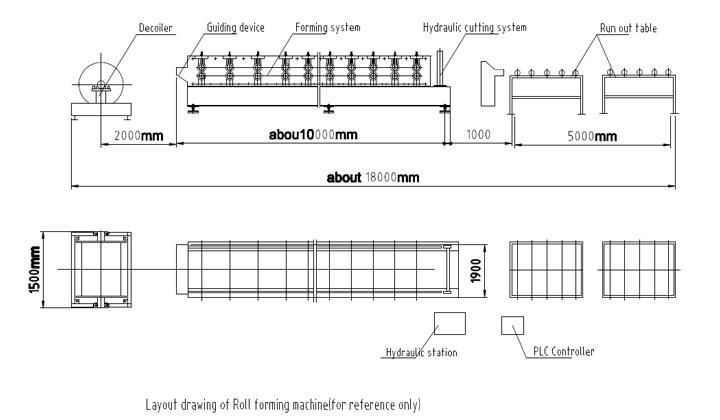

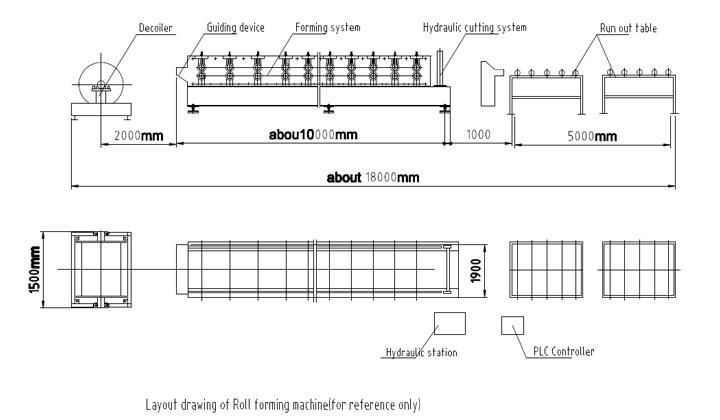

Components of machineDecoiler (manual decoiler and hydraulic decoiler

for option)1set Feeding & guiding device 1set Main roll forming machine 1set Hydraulic cutting system 1set Controlling system 1set Run out table (auto. Stacker for option) 1set

Process flow:

Decoiler -- Feeding & Guiding -- Roll forming---Hydraulic Cutting - product to run out table

Packing:

1. One 40feet container for loading one set machine with mechanical decoiler.

2. Main machine body and decoiler is load naked (tighten to container with steel wire rope).

3. Spare parts and operating tools are loading in tooling box.

Delivery : about 50 days after received advaced payment

Raw Material

Components of machineDecoiler (manual decoiler and hydraulic decoiler

for option)

Process flow:

Decoiler -- Feeding & Guiding -- Roll forming---Hydraulic Cutting - product to run out table

Packing:

1. One 40feet container for loading one set machine with mechanical decoiler.

2. Main machine body and decoiler is load naked (tighten to container with steel wire rope).

3. Spare parts and operating tools are loading in tooling box.

Delivery : about 50 days after received advaced payment