R9m 5 Strand Billet & Round Continuous Casting Machine

Ningbo Ville Electric Co., Ltd.- Control Type:PLC

- Customized:Customized

- Condition:New

- Automatic Grade:Automatic

- Certification:CE, ISO9001

- Type:Special Casting

Base Info

- Model NO.:CCM

- Transport Package:Nude and Wooden Case

- Specification:As per drawing

- Trademark:VILLE

- Origin:China

- HS Code:8454302900

- Production Capacity:50sets Per Year

Description

Basic Info.

Model NO. CCM Transport Package Nude and Wooden Case Specification As per drawing Trademark VILLE Origin China HS Code 8454302900 Production Capacity 50sets Per YearProduct Description

1. PRODUCTION REQUIREMENTS| ITEM | PARAMETER |

| Outfit sections to be cast | 130´130,150´150 180´180,200´200,Φ220,Φ260 |

| Cut-off length | 6 -12 m |

| Steel grade to be cast | Low carbon steel Low alloy steel Alloy steel |

| Production (TPA) | 60 × 10 4 |

2 MAIN CHARACTERISTICS OF THE CASTER

| ITEM | PARAMETER AFTER MODIFICATION |

| - CCM type | Rigid dummy bar |

| - Number of strands | 5 |

| - Strand centre distance | 1350 mm |

| - Bending radius | 9 m |

| - Straightening method | Continuous straightening |

| - Metallurgical length | 18.8 m |

| - Outfit sections | 130´130,150´150,180´180,200´200,Φ220,Φ260 |

| - Heat size | 85t |

| - Ladle turret | Fixed type |

| - Tundish car | Liftable |

| - Tundish capacity | 25 t (special.) |

| - Tundish temperture measure | Tundish temperture continuous measuring system |

| - Mould type | 900 mm copper tube |

| - Oscillator | Semi-leaf spring nonsinusoidal oscillating |

| - Dummy bar type | Rigid |

| - Mould level detection | Cs137(With digital electrocylinder for stopper rod) |

| Internal the mould |

| - Secondary cooling | Air-mist cooling |

| - Withdrawal & straightener | 4module |

| - Roller table | Individual rolls |

| - Roller table pass line level | +0.800 mm |

| - Cutting | Oxy-cutting , Automatic torch cutting machine |

| - Cutting length | 6.0 - 12.0 m |

| - discharge area | Discharge roller table + billet shifter + Two diretions cross transfer car + intermediate cooling bed +turnover cooling bed + billet collecting bank |

3 MAIN PROCESS TECHNOLOGY

For this new 6-strand billet continuous casting machine, the advanced , practical and convenience equipmentsare selected . The main process technology is as below:

1.Protective casting in whole process

2. Integral electrical control and L1 automation system

3. Discharge system including cross transfer car , turnover cooling bed

4. Automatic torch cutting machine

5. Full water-cooled auxiliary withdrawal unit

6. Full water-cooled withdrawal & straightening unit

7. Continuous straightening

8. Automatic secondary Air-mist cooling system

9. Nonsinussoidal oscillating mode driven by digital electrocylinder

10. Semi-leaf spring mould oscillator

11. Automatic mould level control system

12. Internal the mould M-EMS

13. High-efficiency continuous-taper curved surface mould

14.Tundish temperture continuous measuring system

15. Large capacity tundish and alkaline refractory lining

16. Liftable type tundish car for submerged casting

17. Fixed ladle turret with weighting device

18. Self-adaptive rigid dummy bar and dummy bar storage unit driven by motor

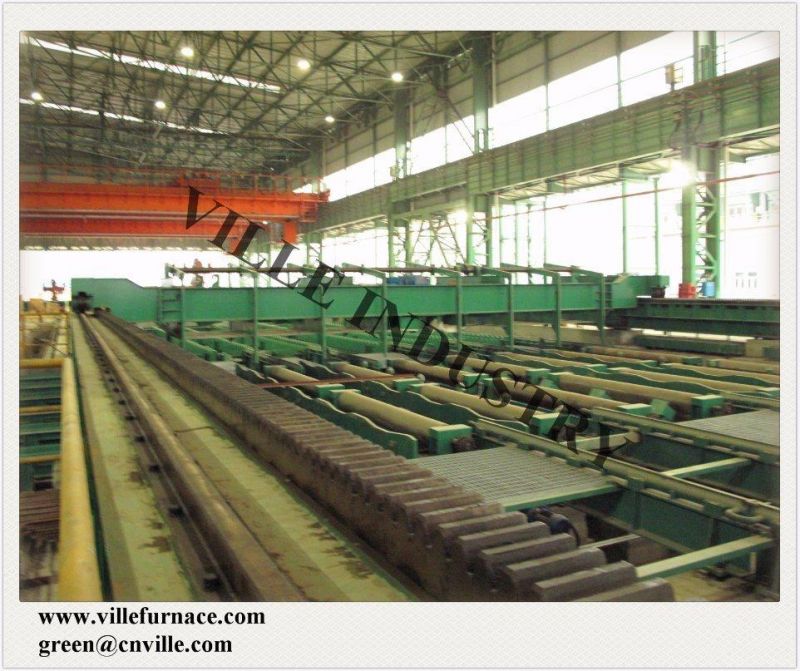

4 Workshop and main manufacturing equipments

Our Best Service For You

| 1. | Pre sale service |

| a. | make technical solution |

| b. | send quotation, technical data sheet and drawing |

| c. | prepare power transmission plan, testing plan and shipment plan |

| 2. | In sale service |

| a. | supervise the manufacturing schedule totally in accordance with the plan |

| b. | send photos to customer during every manufacturing process(hold point) |

| c. | inform the customer one week before testing. |

| 3. | After sale service |

| a. | installation and commissioning, training the workers |

| b. | quick response within 12 hours any time |

| c. | provide 12 months guarantee period normally. |

FAQ For You

| 1. Q: | What is your delivery time ? |

| A: | Depend on the type of transformer. |

| 2. Q: | What is your payment term? |

| A: | 30% advance by T/T , 70% before delivery by T/T or L/C or we can discuss about it. |

| 3. Q: | What kind of standard you follow? |

| A: | IEC, ANSI, CSA, GB, etc |

| 4. Q: | What kind of supporting documentation you can provide normally |

| A: | Quotation, outline drawing, manufacturing plan, quality control plan testing plan, financial report, type test report(KEMA, CESI),reference list, etc |

| 5. Q: | What is your normal warranty period? |

| A: | 12 months after transformer operation. |

| 6. Q: | Can u do installation and commission in user's site? |

| A: | Yes, we can send our installation team to user's country for service. |

| 7. Q: | Do you have any experience in this kind of transformer? |

| A: | Yes, we can provide reference list for check. |

Our advantages:

Quality Assurance

--From the very beginning, VILLE ensures quality in every step to achieve the best quality.

Experience Sharing

--With more than 30 years' experience in power industry, VILLE brings you an optimized solution.

Global Service

--Wherever you are, VILLE global network will support and provide you with value.

Quick Response

--In response to your needs without delay, VILLE knows the value of your time.

Thanks for choosing VILLE as your reliable partner and

please trust both of us will create a brilliant future!