Dx Metal Bending Machine/Curve Steel Bending Machine

Cangzhou Dixin Roll Forming Machine Co., Ltd.- Forging Forming Method:Free Forging

- Power Source:Electric

Base Info

- Model NO.:DX 840,1045,1050,760--

- Feature:Automation

- Certification:CCC, ISO9001, CE

- Warranty:12 Months

- Customized:Customized

- Advantage:Easy to Maintenance

- Condition:New

- Item Name:Metal Bending Machine,Curve Steel Bending Machine

- Feeding Material:Trapezoidal Roof Sheet Panel

- Feeding Thickness:0.2-0.8mm

- Forming Speed:2-4m,Min

- Crimping Radian:Adjustable by PLC Computer

- Control Part:Delta PLC Control with Inverter; Frequency Convert

- Curving Mold:Cr 12 High Quenching with High Temperaute 62

- Max Production Order:Three

- Special Design:Yes

- Machine Size:3000mm*1500mm*1600mm

- Transport Package:Fit for Container Loading

- Specification:DX 840 or as your panel drawing

- Trademark:DX

- Origin:China, Hebei

- HS Code:84552210

- Production Capacity:23 Sets Per Month

Description

Basic Info.

Model NO. DX 840/1045/1050/760-- Feature Automation Certification CCC, ISO9001, CE Warranty 12 Months Customized Customized Advantage Easy to Maintenance Condition New Item Name Metal Bending Machine/Curve Steel Bending Machine Feeding Material Trapezoidal Roof Sheet Panel Feeding Thickness 0.2-0.8mm Forming Speed 2-4m/Min Crimping Radian Adjustable by PLC Computer Control Part Delta PLC Control with Inverter; Frequency Convert Curving Mold Cr 12 High Quenching with High Temperaute 62 Max Production Order Three Special Design Yes Machine Size 3000mm*1500mm*1600mm Transport Package Fit for Container Loading Specification DX 840 or as your panel drawing Trademark DX Origin China, Hebei HS Code 84552210 Production Capacity 23 Sets Per MonthProduct Description

Dx Metal Bending Machine/Curve Steel Bending MachineThe Roof sheets made by our Roofing sheet profile crimp curving arch roll forming machine have beautiful appearance and bright color.

They are widely used in gardens, factories, resorts, hotels, exhibition halls, vacationlands,

ancient architectures and modern villas.

1. Parametets of this curved machine| 1.Processing material | aluzinc/galvanized steel/colored steel coil |

| 0.3-0.8mm |

| As design |

| As design |

| 4kw |

| 4kw |

| 75mm |

| Up three steps , down 4 steps |

| 300H Steel frame |

| 16mm |

| 45# forged steel, with hard chrome plating |

| Delta PLC control system with touch screen |

| Cr12 |

| About 2-4m/min |

| 1 inch chain drive |

| About 2500*1500*1400mm |

| About 1.2on |

| 380v,3phase,50hz or accodring to customer request |

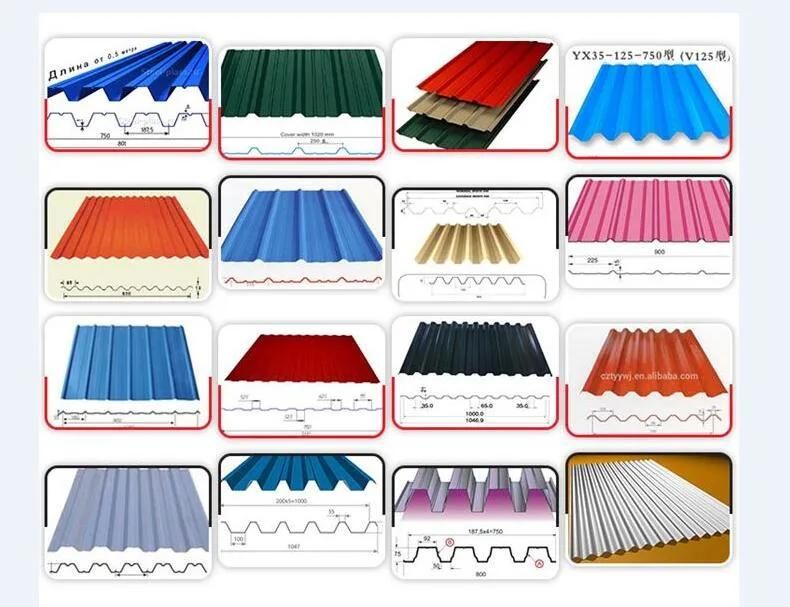

3.Similar machine pictures for your reference.

This type of curved sheet has advantage inclouding beautiful, classical appearance and grace taste.

It can be widely used in village, hotel, exhibition, vocation vallage, family construction and outdoor decorate.

Packing and shipping details

B. Consist of:

(1)Main curving part

(2)PLC computer part

(3)Hydraulic pump station

C. Special design available

(1)Send me your exact panel drawing by e-mail

(2)Post me exact panel profile for curving by DHL, EMS or others.

D. Two kinds of power kind=Two kind of speed choose

(1)You can choose electric motor drive:

Forming speed: 2m/min

(2)Or you can choose hydraulic moter drive,

Fast forming speed: 2-4m/min

E. Welcome to visit our factory.

(if you are in China now, we can pick you up if near. Welcome to our factory very much)

Cangzhou Dixin Roll Forming Machine Co., Ltd

ADD: Fuzhuang development, city botou, Privince Hebei Cangzhou, China

Near Capital Beijing

F. How to get our factory

Some others drawing for your reference.

We provide an extensive line of products, including: roof and wall panel machine, tile roof machine, purline forming machine,

shutter door machine, floor decking machine and other associated equipment.

Our roll forming machines are equipped with PLC control to ensure high accuracy and easy operation.