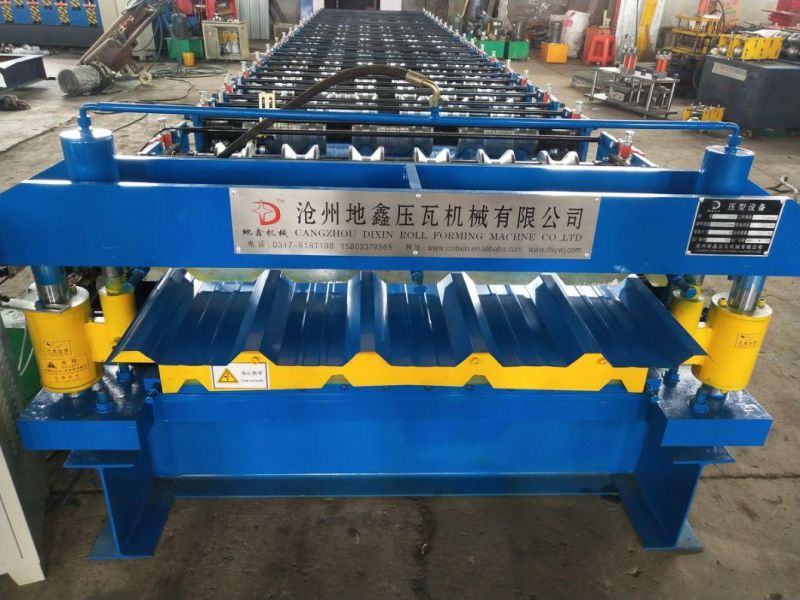

Metal Roof Sheet Double Layer Roll Forming Machine

Cangzhou Dixin Roll Forming Machine Co., Ltd.- Forging Forming Method:Mold Forging

- Power Source:Hydraulic Pressure

Base Info

- Model NO.:DX 840,900

- Feature:Automation

- Certification:CCC, ISO9001, CE

- Warranty:12 Months

- Customized:Customized

- Advantage:Work Flexible

- Condition:New

- Name:Metal Roof Sheet Double Layer Roll Forming Machine

- Appearance Size:6500 Mm * 1300 Mm * 1300 Mm

- Total Weight:3600 Kg

- Plate Thickness:16 Mm

- Line Number:Upper: 9 Row (900) The Lower: 11 Row (840).

- Shaft Material:45 # Steel Quenching Process

- Motor Power:4 Kw

- Host Power:3 Kw

- Shaping Speed:8-15m,Min

- Rolling Material Thicknes:0.3 0.8 Mm

- Transport Package:Water-Proof Packaging, Covered with Plastic Film

- Specification:DX 25-210-840 , DX15-225-900

- Trademark:DIXIN

- Origin:Botou Hebei China

- HS Code:845522

- Production Capacity:20 Set Per Month

Description

Basic Info.

Model NO. DX 840/900 Feature Automation Certification CCC, ISO9001, CE Warranty 12 Months Customized Customized Advantage Work Flexible Condition New Name Metal Roof Sheet Double Layer Roll Forming Machine Appearance Size 6500 Mm * 1300 Mm * 1300 Mm Total Weight 3600 Kg Plate Thickness 16 Mm Line Number Upper: 9 Row (900) The Lower: 11 Row (840). Shaft Material 45 # Steel Quenching Process Motor Power 4 Kw Host Power 3 Kw Shaping Speed 8-15m/Min Rolling Material Thicknes 0.3 0.8 Mm Transport Package Water-Proof Packaging, Covered with Plastic Film Specification DX 25-210-840 / DX15-225-900 Trademark DIXIN Origin Botou Hebei China HS Code 845522 Production Capacity 20 Set Per MonthProduct Description

Metal roof sheet double layer roll forming machine1. Introduction:

The two kinds of models are perfect unifies in together, reasonable structure, beautiful appearance. Has the characteristic such as save floor space, simple operation, especially suitable for small venues and site construction of customers to use.

This machine is mainly composed of feed import platform, forming host, forming shear device, hydraulic station, computer control system and so on several parts.

On the lower conversion operation is simple, just by the transformation of the electric control ark button control, each layer to transform power can also be used by clutch control each layer respectively.

The optional configuration has common feeding machine, hydraulic feeding machine.

The lower level of types according to customer requirements.

2.Equipment detailed parameters:

| 1.Processing material | aluzinc/galvanized steel/colored steel coil |

| 2.Material thickness | 0.25-0.8mm |

| 3.Feeding width: | 1220mm as drawing |

| 4.Effective width | 1000mm as drawing |

| 5.Main motor power | 7.5kw |

| 6.hydraulic pump power | 5.5kw |

| 7. Shaft diameter | 75mm |

| 8.Forming steps | Two layer both 18steps |

| 9.Main frame | 350H Steel frame |

| 10. Side plate thickness | 16mm |

| 11.Roller material | 45# forged steel, with hard chrome plating |

| 12.Control systerm | (Panasonic)PLC control withTouch Screen, Mitsubishi frequency converter Encoder(Omron) |

| 13.Cutting blade material | Cr12 |

| 14.Working speed | About 10-15m/min |

| 15. Transmission way | 1 inch chain drive |

| 16. Machine size (mm) | About 8800*1700*1400mm |

| 17. Machine weight | About 6.5ton |

| 18.Power supply | 220V,2 PHASE ,50HZ (according to your request) |

4.Advantages:

Double color steel watts economical equipment, two models can be a device synthesis, namely save area, and double costs are much lower than the two single machine, users are preferred.

This equipment adopts the latest double design, one machine amphibious, cover an area of an area small, easy to transport, cost savings

5.Packing and shipping details

1. Need one 40ft container.

2. Fit for ocean shipping.

3. The main body of the roll forming machine will be naked packing into the container, covered with plastic film.

4. Steel wire fixes the machine into the container, in case of any damage when shaking on the sea.

5. The spare parts will be packed into the carton box.

6. The received goods table put into a carton box.

7. Manual decoiler naked package.

6. Our service:

Maintenance period: One year

After-sales service: If the buyers need, we can send our technical staff to the buyers' place

To debug the machine and providing the training in 30 days after the machines arrive at the destination port.

The debugging fees: Free

The training fees: USD80/day for each technical person.