Metal Roof Sheet Curving Machine/Sheet Rolling Machine

Cangzhou Dixin Roll Forming Machine Co., Ltd.- Forging Forming Method:Free Forging

- Power Source:Electric

Base Info

- Model NO.:DX 1045,1025,1050---

- Feature:Automation

- Certification:CCC, ISO9001, CE

- Warranty:12 Months

- Customized:Customized

- Advantage:Easy to Maintenance

- Condition:New

- Item Name:Metal Sheet Metal Folding Machine

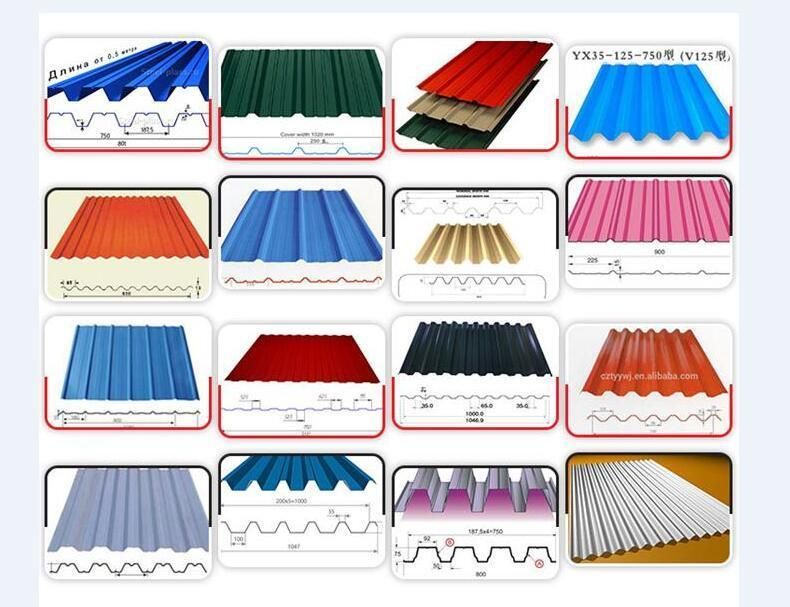

- Feeding Material:Trapezoidal Roof Sheet Panel

- Feeding Thickness:0.2-0.8mm

- Forming Speed:2-4m,Min

- Crimping Radian:Adjustable by PLC Computer

- Control Part:Delta PLC Control with Inverter; Frequency Convert

- Curving Mold:Cr 12 High Quenching with High Temperaute 62

- Max Production Order:Three

- Special Design:Yes

- Machine Size:8500mm*1500mm*1600mm

- Transport Package:Fit for Container Loading

- Specification:DX 840 or as your panel drawing

- Trademark:DX

- Origin:China, Hebei

- HS Code:84552210

- Production Capacity:19 Sets Per Month

Description

Basic Info.

Model NO. DX 1045/1025/1050--- Feature Automation Certification CCC, ISO9001, CE Warranty 12 Months Customized Customized Advantage Easy to Maintenance Condition New Item Name Metal Sheet Metal Folding Machine Feeding Material Trapezoidal Roof Sheet Panel Feeding Thickness 0.2-0.8mm Forming Speed 2-4m/Min Crimping Radian Adjustable by PLC Computer Control Part Delta PLC Control with Inverter; Frequency Convert Curving Mold Cr 12 High Quenching with High Temperaute 62 Max Production Order Three Special Design Yes Machine Size 8500mm*1500mm*1600mm Transport Package Fit for Container Loading Specification DX 840 or as your panel drawing Trademark DX Origin China, Hebei HS Code 84552210 Production Capacity 19 Sets Per MonthProduct Description

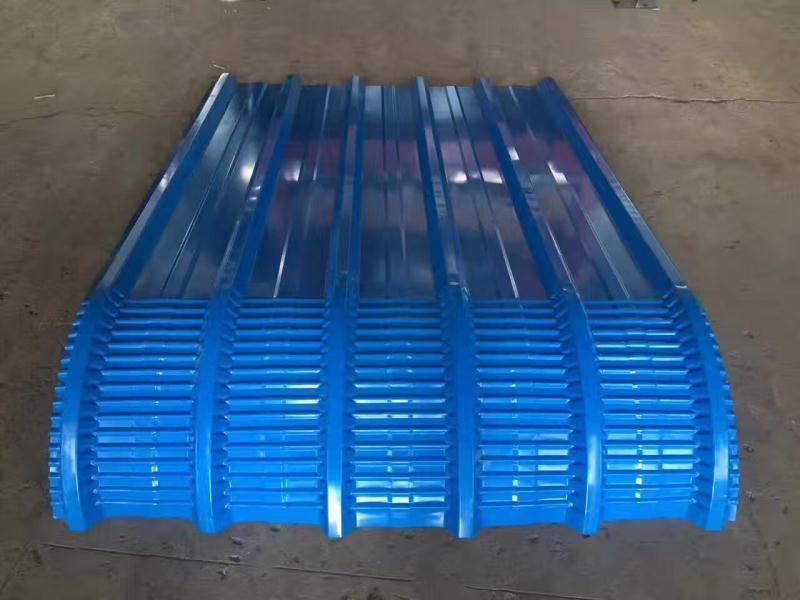

Metal roof sheet curving Machine/sheet rolling machine

1.Machine Technique parameters

| 1.Processing material | aluzinc/galvanized steel/colored steel coil |

| 2.Material thickness | 0.25-0.8mm |

| 3.Feeding width: | IBR sheet as customers drawing |

| 4.Effective width | IBR sheet as customers drawing |

| 5.Main motor power | 4kw with servo motor |

| 6.Pump station power | 4kw |

| 7. Shaft diameter | 75mm |

| 8.Forming steps | Top 2 steps, down 4 steps, as machine pictures. |

| 9.Main frame | 300H steel frame |

| 10. Side plate thickness | 16mm |

| 11.Roller material | 45# forged steel, with hard chrome plating |

| 12.Control systerm | (Taiwan brand)Delta PLC control system with touch screen |

| 13.Cutting blade material | Cr12 |

| 14.Working speed | About 3-5m/min |

| 15. Transmission way | 1 inch chain drive |

| 16. Machine size (mm) | About 2000*1500*1300mm |

| 17. Machine weight | About1.5ton |

| 18.Power supply | 380v,3phase,50hz or accodring to customer request |

3.Components of production line

| No. | Name | Unit | Qty |

| 1 | Main forming machine | set | 1 |

| 2 | Delta PLC control system | set | 1 |

| 3 | Normal cutting system | set | 1 |

| 4 | Electric motor | set | 1 |

| 5 | Spare parts | box | 1 |

4.Packing and shipping details

Export standard packing:

1.The main body of the roll forming machine will be naked packing into the container,covered with plastic film.

2.Steel wire fix the machine into the container, in case any damage when shaking on the sea.

3.The spare parts will be packed into the carton box.

4.The received goods table put into carton box .

5.Manual decoiler naked package .

5.Our service

1. Warranty :One year,and we will provide technical support for whole life of the equipment.

2. Delivery time: Within 25 days after deposit receipt your payment

3. Guarantee period: 24months free service/ pay service all the machine life

4. Installation and training

If buyers visit our factory and check the machine, we will teach you how to install and use the machine and also train your workers/technician face to face.

6.About our company

Cangzhou Dixin Roll Forming Machine Co.,ltd is a professional manufacturer and exporter which has its own factory and also cooperate with several production factories and associated enterprises, concerning with the design, development and production of cold roll forming machines,material of building. We specialize in the automated production line of sheet cold roll forming machines. We are able to provide an integral resolution schema of cold roll forming system through a combination of advanced system design and equipment. Based on our advanced research and commercial team, we are able to research and development, manufacturing and sale of standard and non-standard cold roll forming equipment for our clients world widely.

We provide an extensive line of products, including: roof and wall panel machine, tile roof machine, purline forming machine,shutter door machine, floor decking machine and other associated equipment. Our roll forming machines are equipped with PLC control to ensure high accuracy and easy operation.

FAQ

1. You are the manuafacturer or trading company ?

A: We are the professional manufacturer , and we have more than 20 years professional experiece in the field of roll forming machine.

2. Can you make the machine according to my design or photo type?

A: Yes. We have an experienced team to work out the most suitable design and production plan

for the machine.

3. How can we be assured that you will deliver us quality machine with spare parts?

A:1. Customers to send the technical people to our factory for checking the quality.

2.We can send the technicians to the buyer`s factory for the installation of the machine.

4.What policy of your garentee?

A: Within the One-YEARS period, we could supply you the replacement parts free of charge

for any damaged parts caused by quality problems after two years,you need to buy by factory cost.