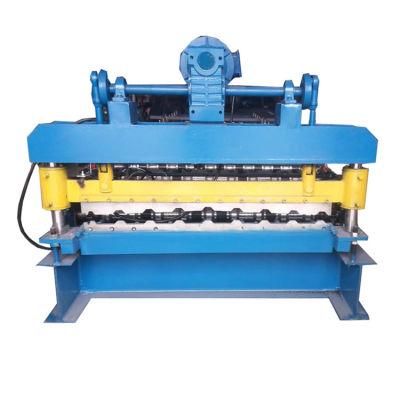

0.8mm Thickness 1090 Aluminium Sheet Roll Forming Equipment

Cangzhou Dixin Roll Forming Machine Co., Ltd.- Forging Forming Method:Mold Forging

- Power Source:Hydraulic Pressure

Base Info

- Model NO.:Aluminium Sheet Roll Forming Equipment

- Feature:Automation

- Certification:CCC, ISO9001, CE

- Warranty:12 Months

- Customized:Customized

- Advantage:Use Widely

- Condition:New

- Machine Type:Sheet Roll Forming Equipment

- Applied Slad Thicknedd:0.7-0.8mm

- Charge in Width:1000mm-1200mm

- Productivity:0-15m,Min

- Rollers:13----18 Rows

- Diameter of The Roller:75mm

- Dimensions: Major Structure:7.8m×1.8m ×1.4m

- Weight:4.3t

- Power:4kw+3kw

- Name:0.8mm Thickness 1090 Aluminium Sheet Roll Forming

- Transport Package:Water-Proof Packaging, Covered with Plastic Film

- Specification:CE ISO

- Trademark:DIXIN

- Origin:Botou Hebei China

- HS Code:84552210

- Production Capacity:20 Set Per Year

Description

2.Process flow: loading---molding----cutting----off-discharging

3.Packing and shipping details

Nude packing in the 40 feet container ,fixed well with oil rope, control cabinet and all the accessories with waterproof.

4.Company Introduce:

Our enterprise, Cangzhou Dixin Roll Forming Machine Co., Ltd, as the professional and leading manufacturer, can manufacture, design, installation and debug various roll forming machines and metal processing sheet equipments, which produce metal roof wall panel, glazed roof tile, CZ steel purlin, floor decking, roof ridge cap, sandwich panel, roof truss, shutter panel, shutter slat, door frame, guardrail, and metal sheet uncoiler, bending, slitting, cutting, flattening, punching, crimping.

Backed by reasonable design, precision machining and selected material, both our standard and customized machines are characterized by long life span, precise forming and easy operation. With our customers' trust, our machines have been sent to America, Australia, Russia, India, Sri Lanka, Nigeria, Pakistan, Uzbekistan, Mozambique, Angola, Turkey, Brazil, etc.

Warmly welcome to China to visit our factory and select the machines you need. Our address,Fuzhuang Industrial Development Zone, Botou City, Hebei Province, China

5.Our Services

First,we can produce the special machine,send your drawing to us,we can design for you.

Second,if you buy our products,we also can help you to purchase the material,like color roll,the price is lower than you buy by yourself.

Third, we provide a one year warranty and lifelong technical support,we can send our technicians to you to give you on-site training.

Four,engineers available to service machinery overseas.

Five, if you come to visit our factory,we can book the room for you,car pick up to send.

We manufacture and test our machine strictly to make sure every customer get it satisfied.

Your panel profile drawing is welcomed and acceptable!

Some FAQ:

Some FAQ:Q1. What are the main key points for selecting right machines?

A1: Whole structure,Roller Shaft,Roller Material,Motor&Pump,and Control system. As the new buyer, please kindly know that price

not the final point.

Good quality is for long-term business cooperation.

Q2. Can you provide OEM service for roll forming machine?

A2: Yes, most of cold roll forming machine need to be customized as detailed request, because raw material , size , production

usage, machine speed, then machine specification will be some different.

Q3. What's your standard trade terms ?

A2: We can provide the technical offer with FOB,CFR,CIF,Door to Door and so on. Please kindly tell the detailed port name for

competitive ocean freight.

Q4. How about the quality control?

A4: Our company adopts 6S system to control every part with passed ISO9001:2000, CE,TUV/BV(Alibaba) Certificate.

Q5. How about the after-sale service?

A5: We provide 18 months free warranty and free technical support for the whole life of any machine. During warranty period, if

parts still broken, we can send the new ones freely.

Q6. If I am in Beijing,Shanghai or Guangzhou,how to visit your company?

A6: 1) Beiing South Statioin to Cangzhou West Station (by fast train 1 hour).

2) Shanghai Hongqiao to Cangzhou West (4.5 hours)

3) Guangzhou Airport to Tianjin ,then Tianjin to Cangzhou West