Xbj-18 Double Milling Head Edge Milling Machine

Shanghai Taole Machine Co., Ltd.- After-sales Service:Online Service or Remote Assist

- Warranty:1 Year Guarantee

- Type:Plate Beveling Machine

- Style:Desktop

- Layout:Horizontal

- Automatic Grade:Semi-Automatic

Base Info

- Model NO.:XBJ-3,6,9,12,15,18

- Power Source:Electric

- Certification:CE, ISO

- Stroke Length:2,3,6,12,15,18,20 Meter

- Plate Thickness:4-300mm

- Top Bevel Angel:0-85 Degree

- Bottom Bevel Angel:0--45 Degree

- Transport Package:Pallet and Wrapping in Ot Container

- Specification:6 meter length stroke

- Trademark:TAOLE

- Origin:Shanghai, China

- HS Code:846190

- Production Capacity:20 Sets Per Month

Description

Basic Info.

Model NO. XBJ-3/6/9/12/15/18 Power Source Electric Certification CE, ISO Stroke Length 2/3/6/12/15/18/20 Meter Plate Thickness 4-300mm Top Bevel Angel 0-85 Degree Bottom Bevel Angel 0--45 Degree Transport Package Pallet and Wrapping in Ot Container Specification 6 meter length stroke Trademark TAOLE Origin Shanghai, China HS Code 846190 Production Capacity 20 Sets Per MonthProduct Description

Xbj-18 Double Milling Head Edge Milling MachineGMM-Series edge milling machine designed based on metal edge planer, edge shaving machine for weld preparation with more energy saving. Widely used for welding industry, pressure vessel, ship building, electricity, chemical engineering, steel construction and so on. It becomes a essential equipment for welding.

GMM-S/D Series Models

- GMM Edge milling machine with stroke option of 2 Meters,4m,6m,9m,12m etc.

- Same model with single spindle or double spindle as option. D model means double heads. S model means single head.

Equipment Composition:

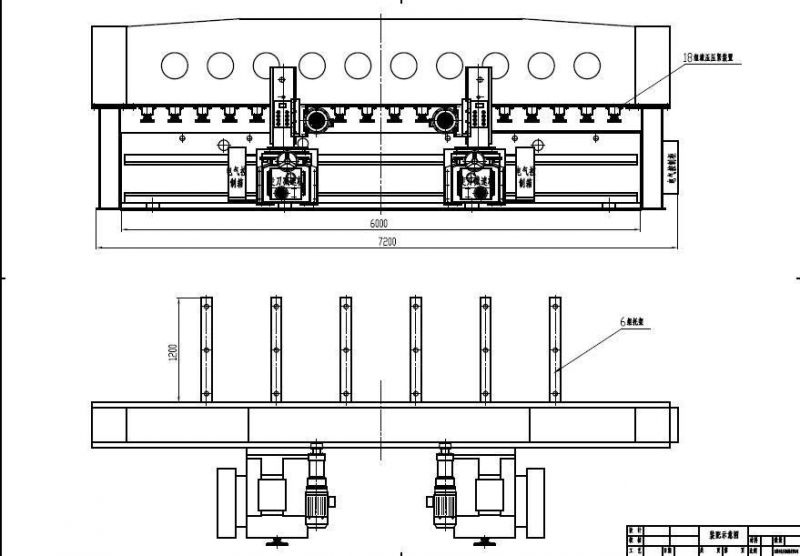

Machine including below main parts: 1) Machine Body 2)Machine Column 3) Material Clamping Beam 4) Hydro cylinder 5) Rise and Fall Pillar 6) Milling Spindle Head 7) Power Drive 8) Guide Rail 9) Milling Head 10) Hydraulic Control System 11) Electric control box 12) Lubrication device 13) Conductive Device 14) Protection Device 15) Position Device 16) Material Feeding Device 17) Painting

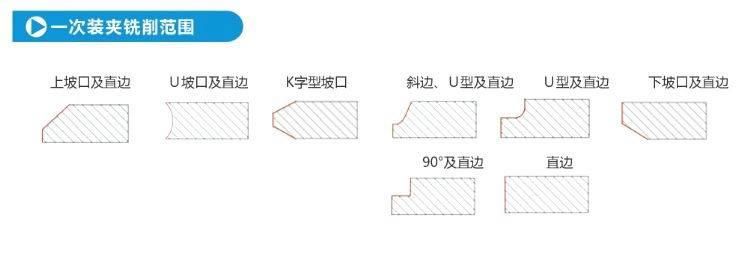

Equipment Functions for Xbj-18 Double Milling Head Edge Milling Machine

| Double Spindle Heads | Two Seperate Spindle Head and Drive Device on Guide Rail. Both heads could achieve plate beveling. When both heads working on same plates.Could achieve max plate stroke at 6 meters. Main Function: 1)When Thick plate with bevel angel. It could be more efficiency. 2)Machine will be cost effective while need K/X bevel or large bevel QTY |

| Working Stoke | GMM-D6000 means 6000mm(6 Meters) Stroke Double Spindle Heads could be same direction with effective stroke at 6 meters for both Spindle Heads. |

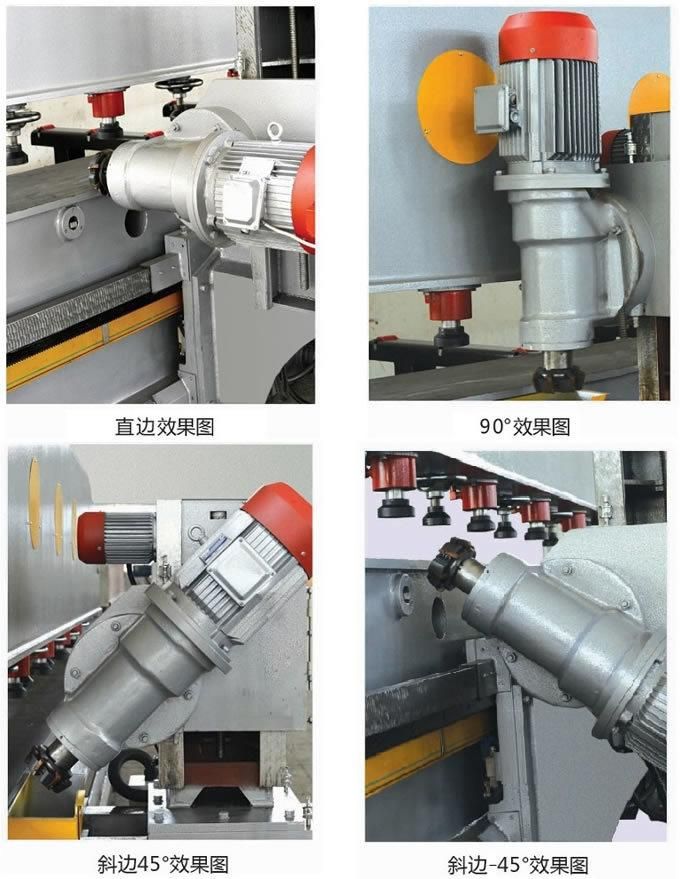

| Double Sided Edge Milling | Could process double sided beveling by adjusting bevel angel. No need second machine adjustment. Both milling head could be adjustable between - 45 degree to 85 degree |

| Full Hydraulic Cylinder | Plate Pressure by Cylinder in 6 meters. Pressure Foot Size can be customized as per plate sizes. (Specially on Small plates) 6 meters stroke with total 15 sets of pressure Foot, Clamping plate 200*100mm suggested to ensure high pressure |

| Inlaying Steel Guide Way | Milling Machine guide Rail adopts integral one-time molding, service life could be 20 years. Small bed deformation leads structure more firm and stable. Guide rial surface artificial scraper grind cross-stitch, increase the drag plate and wear surface with section 40 Cr Steel bar.Completely solve the problems. Low shaking, high speed, higher surface performance, less blade loss. |

| Walking Reducer | Hard surface parallel helical gear low noise high torque reducer Model:FCA77/142.27-IEC90B5/YF90L-4 Adjustable, Higher speed on walking and return could reach 450-2500mm/min Setting with Brand VFD |

| Milling Head Motor | Motor Power 7.5KW,Using Siemens Brand Spindle Speed adjustable for multi metal material |

| Complete Machine Design | Complete machine design for improving edge milling machine Linear accuracy and rigid strength |

| Support Bracket | Support bracket length2 meters and width 1.2 meters for better metal support considering the machines sizes and plate sizes. |

| Milling End Positioning Device | Positioning Device setting at table edge which is easy to remove or load. This stopper is suitable for processing small plate and thin plate which is convenient and fast. |

| Hydraulic Pressure Device | Dynamic Pressure retaining system. Power saving and prolong service life |

| Electric Parts | Complete electric components are 95% Brands |