Chromcarbid Beschichuntung/Laserbeschriftung/Laser Markingprocessing Technology/Metal Parts

Dongguan Wuxin Automation Technology Co., Ltd.- After-sales Service:One-to-One After-Sales

- Condition:New

- Certification:ISO9001

- Customized:Customized

- Material:Stainless Steel

- Application:Metal Processing Machinery Parts

Base Info

- Quality:ISO9001:2015, 100% Full Inspection

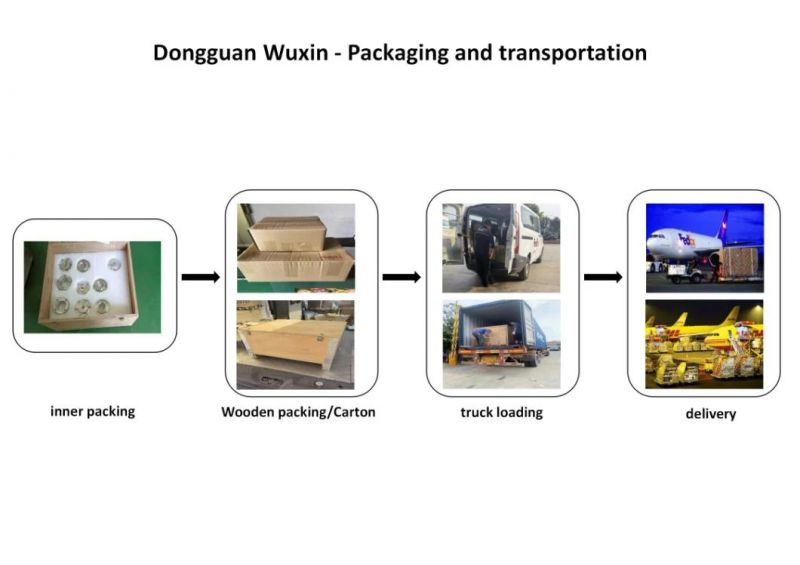

- Transport Package:Separate Packing + Wooden Cases,Carton

- Specification:Customer Required

- Trademark:OEM,ODM

- Origin:Guangdong, China

- Production Capacity:30000PCS,Month

Description

Basic Info.

Quality ISO9001:2015, 100% Full Inspection Transport Package Separate Packing + Wooden Cases/Carton Specification Customer Required Trademark OEM/ODM Origin Guangdong, China Production Capacity 30000PCS/MonthProduct Description

We are the production of automation equipment non-standard parts; High-precision parts; Precision fixture; and all kinds of metal parts .

| Material | Stainless steel: SUS303, SUS304, SUS316, SUS316L, SUS430, SUS440, etc. Aluminum: 6061-T6, 6063-T5, 7075-T6, 2011, 2017, 2024, 5052, 5083, 6082 etc. Brass/copper: C11000, C10200, C12000, C26000, C36000, etc. Carbon steel: Q235,S235JR,1010, 1015, 1020, 1025, 1030, 1035, 1040, 1045, etc. Plastic: PVC, POM, Telfon, Delrin, PEEK ,Nylon, ABS, PC, PP,PA6, PA66, etc. Free cutting steel: 1211, 12L13, 12L14, 1215, etc. Tool Steel: SKD61,SKD11,HSS M2,ASP23 .,H13,1.2344,D2,1.2379,etc. Alloy steel: 40Cr,15CrMo,4140,4340,35CrMo,16MnCr5 Titanium alloy. |

| Processing Craft | Drawings→ Write process flow → cutting → CNC machining→surface treatment →product checking→ packing →delivery Or: Drawings→ mould making → die casting →rough machining → CNC machining→surface treatment →product checking→ packing →delivery; |

| Tolerance | ± 0.005mm |

| Surface Treatment | Electroplating, Chrome Plating, Zinc Plating, Nickel plating, Electrophoresis, Anodization, Polishing, Sandblasting, Passivation, Powder coating, Spray painting, Etc. |

| Quality Assurance | ISO9001:2015 Certified, SGS Certification |

| Quality Guarantee | 1 years |

| Inspection | 1)During processing, the operating machine worker inspect the each sizes by themselves. 2)After finished the first whole part, will show to QA for full inspection. 3)Before shipment, the QA will inspect according to ISO sampling inspection standard for mass production. Will do 100% full checking for small QTY. |

| Mainly Testing Facility | Three coordinates; Height gauge; Tool microscope; A projector. Micrometer series; Roughness instrument; Hardness tester And other testing equipment. |

| Features & Advantage | 1)Competitive price. 2)High quality control : 100% full inspection before shipment. 3)High precision, tolerance can be ± 0.005mm. 4)Fast lead time (5-7days for samples, 12-15 days for mass production) 5)Non-standard//OEM//customized service provided. 6)No MOQ, small QTY is acceptable. 7)ISO 9001:2015 certificated factory, ROHS material used. 9)Professional export packing: separate Blister plastic box or Bubble Wrap/Pearl Wool +Carton+Wooded Case, keep no scratch and damage. |

| Application | 3C industry, lighting decoration, electrical appliances, auto parts, furniture parts, electric tool, medical equipment, intelligent automation equipment,other metal casting parts. |

DongGuan WuXin Automation Technology Co., LTD won the honorary title of National high-tech Enterprise in 2021. The company fully implements ISO9001:2015 quality management system standard, to ensure product quality and service quality to meet customer needs.

The main production equipment is a variety of large CNC machining center, large gantry CNC, large gantry milling, large gantry grinding, high precision inside and outside circular grinding, and supporting high precision testing equipment.

The main production equipment is a variety of large CNC machining center, large gantry CNC, large gantry milling, large gantry grinding, high precision inside and outside circular grinding, and supporting high precision testing equipment.

WuXin since its inception, has been adhering to the "science and technology as the forerunner, strives for the survival by the quality, reputation and promote development of innovation through research and development" business philosophy and "quality first, customer first, excellence, efforts to develop" the quality policy, with well-known brands in the world has formed a technology strategy cooperation, out of a unique development path. At present, the main CNC precision parts processing, fixture, fixture precision parts manufacturing, and can provide electrostatic powder spraying paint processing, products are widely used in hardware, electrical appliances, electronic components and other manufacturing production, involving network, communications, electronic appliances, light industry, medical and other related industries. Can be customized according to customer needs of various materials machine parts, at the same time has a perfect after-sales service system, so that customers in the process of using no worries.

WuXin since its inception, has been adhering to the "science and technology as the forerunner, strives for the survival by the quality, reputation and promote development of innovation through research and development" business philosophy and "quality first, customer first, excellence, efforts to develop" the quality policy, with well-known brands in the world has formed a technology strategy cooperation, out of a unique development path. At present, the main CNC precision parts processing, fixture, fixture precision parts manufacturing, and can provide electrostatic powder spraying paint processing, products are widely used in hardware, electrical appliances, electronic components and other manufacturing production, involving network, communications, electronic appliances, light industry, medical and other related industries. Can be customized according to customer needs of various materials machine parts, at the same time has a perfect after-sales service system, so that customers in the process of using no worries. WuXin was an OEM and ODM supplier ,but in China has its own product brand,invention patents, utility model patents. And it has successful foreign trading experience in Europe, North America and South America.

WuXin was an OEM and ODM supplier ,but in China has its own product brand,invention patents, utility model patents. And it has successful foreign trading experience in Europe, North America and South America.

FAQ

FAQ

1.Are you a manufacturer?

Yes,We are the production of automation equipment non-standard parts; High-precision parts; Precision fixture; and all kinds of metal parts .

2.What's machining equipments do you have ?

CNC CNC machining center;

Walking wire;

Electric spark;

Numerical control car;

Precision grinder and other equipment and supporting large gantry CNC, gantry grinding, gantry milling.

3.Do you have any test equipment?

Three coordinates;

Height gauge;

Tool microscope;

A projector.

Micrometer series;

Roughness instrument;

Hardness tester And other testing equipment.

4.What is your product range?

1.CNC machining parts, precision parts, CNC parts, metal machining parts.

2.CNC turning parts, CNC turned parts,Lathe parts, turned parts.

3.CNC milling parts, CNC milled parts, metal milling parts.

4.CNC machined parts,CNC machine part, CNC machinery parts.

5.Metal parts, Auto parts, mechanical parts.spare parts,accessories,hardware.

6.Die casting parts,aluminum casting parts, Zinc casting parts.

7.Die stamping parts, metal stamping parts, press stamping tooling

8. Sheet metal fabrication, bending parts, laser cutting parts, welding parts.

5.What is material you can process?

Stainless steel: SUS303, SUS304, SUS316, SUS316L, SUS430, SUS440, etc.

Aluminum: 6061-T6, 6063-T5, 7075-T6, 2011, 2017, 2024, 5052, 5083, 6082 etc.

Brass/copper: C11000, C10200, C12000, C26000, C36000, etc.

Carbon steel: Q235,S235JR,1010, 1015, 1020, 1025, 1030, 1035, 1040, 1045, etc.

Plastic: PVC, POM, Telfon, Delrin, PEEK ,Nylon, ABS, PC, PP,PA6, PA66, etc.

Free cutting steel: 1211, 12L13, 12L14, 1215, etc.

Tool Steel: SKD61,SKD11,HSS M2,ASP23 .,H13,1.2344,D2,1.2379,etc.

Alloy steel: 40Cr,15CrMo,4140,4340,35CrMo,16MnCr5

Titanium alloy.

6.What information should i let you know once i want to make a inquiry?

The drawings ( PDF,CAD or 3D ) and the quantity.

7.Will my design/drawing be secured after you get it?

Yes,we will not release your design/drawing to third party unless getting your permission. And we can sign the NDA before you send the drawing /design if required.

8.Can you send to me samples?

1. sample can be provided,but the clients will bear the shipping cost.

2.samples are usually free, except for special parts.

9.How long i can get the quaotation?

After get customer's detail enquiry( Clear drawings, material, QTY, surface treatment).

Normally, we will provide offer within 24 hours(Considering the time difference),and we rest on Sunday.

If more than 100 drawings, will provide price within 36 hours.

10.What's the delivery time ?

Normal s, 5-7 working days;

For mass production, it takes about18 working days.

If any urgent parts, we can provide preferential processing and control the delivery time as you required.

11.How does the WUXIN control the quality?

1)During processing, the operating machine worker inspect the each sizes by themselves.

2)After finished the first whole part, will show to QA for full inspection.

3)Before shipment, the QA will inspect according to ISO sampling inspection standard for mass production. Will do 100% full checking for small QTY.

4) when shipping the goods, we will attached the inspection report with the parts.

12.What is the standard of package?

Professional export packing:

1)Separate Blister plastic box or Bubble Wrap/Pearl Wool, keep no scratch and damage.

2)Most products will be packed in custom wooden cases, and some light ones will be packed in cartons.

13.How to handle the complains?

1)During processing, if found any sizes defective, we will inform the clients and get clients approval.

2)If happen any complaints after got the goods, pls show us photos and detail complaints points, we will check with the production department and QC depart. Immediately and give solving solution with 6 hours.

3)If need re-make, we will arrange re-make urgently and ship you new replacement within 5 days. wuxin will bear all the cost ( include shipping cost).

14.What's the payment term?

Regular customers:30 days monthly settlement , telegraphic transfer.

New customers: 50% payment in advance, balance by telegraphic transfer before delivery.

15.How to ship the parts?

1)Normally, we shipped the goods by DHL,FEDEX ;

3-5 days can arrived the clients' company directly.

2)we Usually shipped by air.

16.What is your main market?

North America, South America, European,Southeast Asia.

17.What benefit we can get from you?

1)Competitive price.

2)High quality control : 100% full inspection before shipment.

3)High precision, tolerance can be ± 0.005mm.

4)Fast lead time (5-7days for samples, 12-15 days for mass production)

5)Non-standard//OEM//customized service provided.

6)No MOQ, small QTY is acceptable.

7)ISO 9001:2015 certificated factory, ROHS material used.

9)Professional export packing: separate Blister plastic box or Bubble Wrap/Pearl Wool +Carton+Wooded Case, keep no scratch and damage.

18.What kind of certificate you have ?

We have ISO9001:2015.