Hcvac Stainless Steel Furniture Metal Vacuum PVD Coating Machine

Guangdong Huicheng Vacuum Technology Co., Ltd.- After-sales Service:Free Installing and Training , Technical Support,

- Warranty:One Year

- Type:Vacuum Coating

- Coating:Vacuum Coating

- Substrate:Steel

- Certification:CE, ISO

Base Info

- Condition:New

- Type 1:Stainless Steel Furniture PVD Coating Machine

- Model:Lh-2200, Lh-3232, Lh-2245

- Chamber Size:Customized

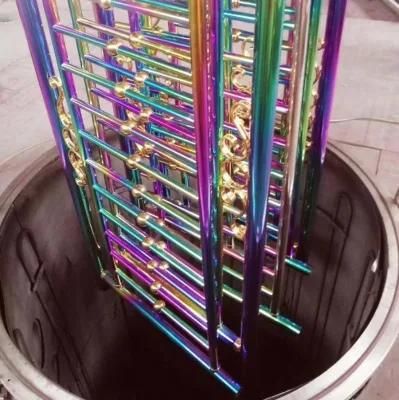

- Coaitng Technology:Multi-Arc Ion Vacuum Coating Machine

- Coating Film:Tin, Tic, Ticn, Tialn, Crn, Cu, Au etc.

- Coating Color:Silver, Golden, Black, Rose Gold, Pink, Bronze, Co

- Coating Material:Stainless Steel, Metal Alloy, Ceramic, Glass etc.

- Application:Stainless Steel Sheet, Pipe, Parts

- Control Mode:Automatic PLC Touch Screen Control

- Brand:Hcvac

- Transport Package:Flat Container

- Specification:customized

- Trademark:HCVAC

- Origin:Guangdong, China

- HS Code:8543300090

Description

Application:

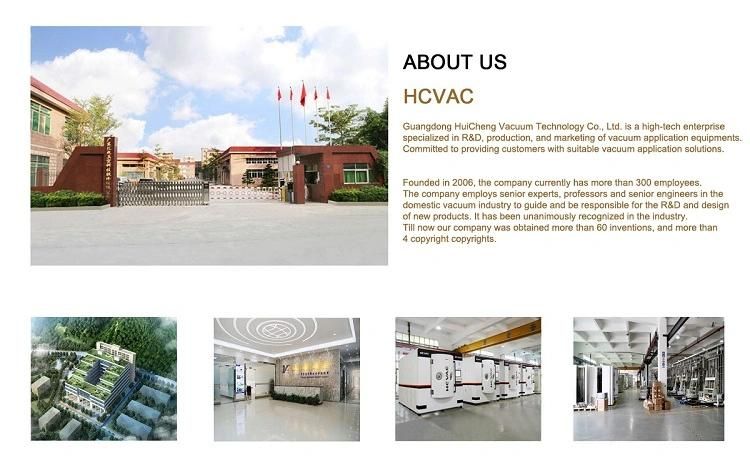

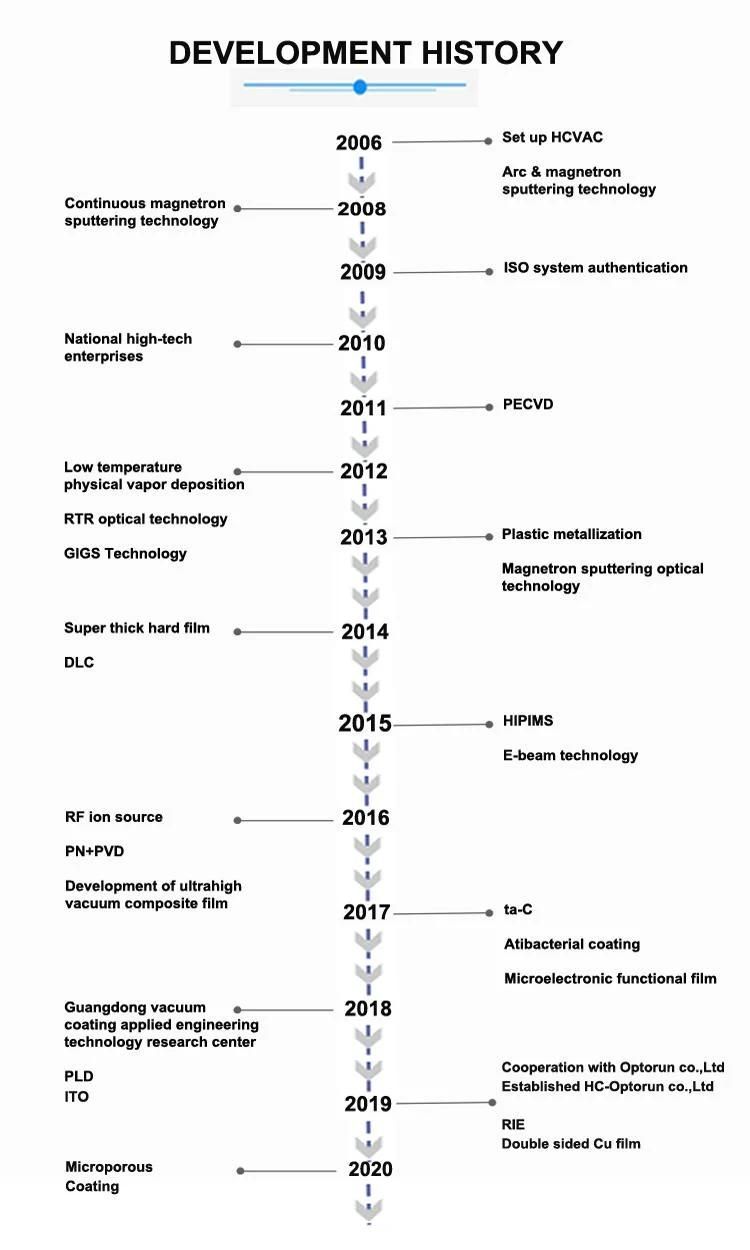

Company Information:

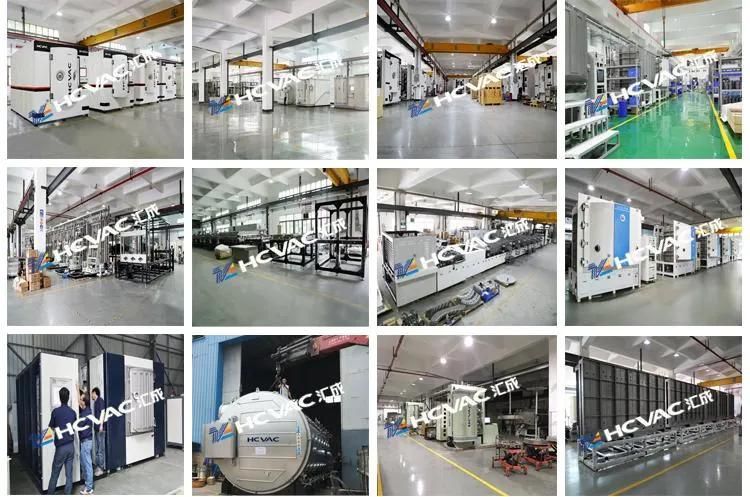

Factory workshop:

Factory workshop:

Certificate:

Delivery:

Clients:

Why Choose HCVAC system?

- Over 3000 plants installed worldwide

- Quick cycle times

- High production capability with low energy consumption

- More up time due to ease of loading/unloading and low maintenance

- High productivity with only a single operator

- Steel process chambers, built to last

- Eco-friendly

- Space saving design

- PVD option available on all plants

- 1 year component warranty and 25 years minimum guaranteed working life

- Complete global network of consulting, engineering and renowned after sales service

We developed a complete after-sales system and effective service measures. Company now owns a professional after-sales service team with more than ten experienced engineers.

HCVAC can help you to enter the PVD coating easily by our vacuum coating machine and full range service. We will provide with most suitable technology according to your requirements.

We will make the full set special coating solution for each customer; combine the full set production technics to meet your requirements, to ensure high efficiency of production.

ISO 9001 standard to ensure the quality can meet the customer's requirements.

Easy to implement:To many people unfamiliar with the process, PVD coating technology seems complicated. However, with the right investments and a good support, it is easier than expected. HCVAC has developed a turnkey coating process that makes a PVD coating centre easy to implement. A complete coating process consists of several steps: stripping (depending on the part's history); pre-treatment; quality control; cleaning & drying; fixturing & visual inspection; PVD coating; quality control & thickness measurement and post-treatment (depending on the application). These steps are all available from one partner: HCVAC Technology, including mature technics and coatings.

Contact us:

Please feel free to contact us for further information!