2D Stainless Steel Metal Wire Forming Machine Automated Wire Bender

Guangzhou DuroWelder Limited- After-sales Service:Online Support

- Automatic Grade:Automatic

- Warranty:1 Year

- Certification:CE

- Model:Wb Series

- Application:Metal Wire Bending

Base Info

- Model NO.:WB

- Current:AC

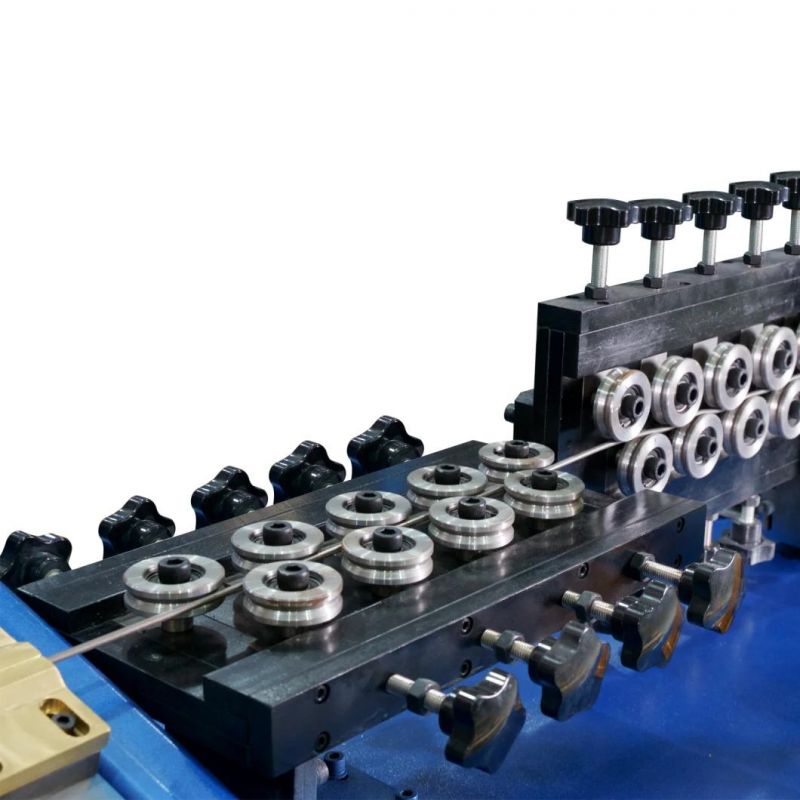

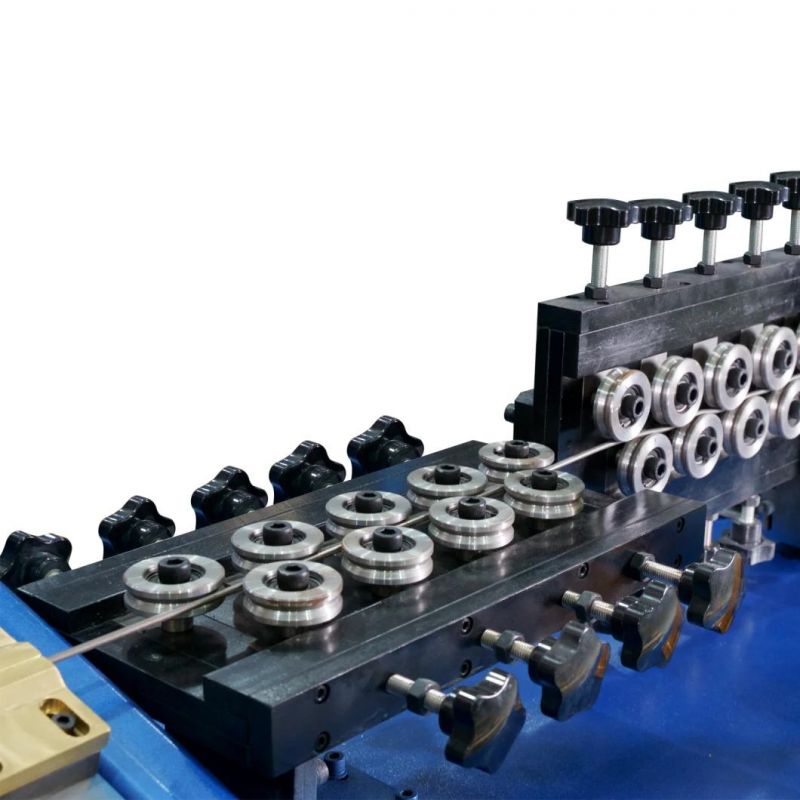

- Wire Diameter:2-12mm

- Transport Package:Plywood Box

- Specification:CCC, ISO, CE

- Trademark:KIA-IND

- Origin:USA and China

- HS Code:8515219000

- Production Capacity:100sets,Year

Description

(1) feed wire Shelve: 500KGS / 1000KGS / 1500 KGS

The working principle of the device:

The equipment selects the subdivision driver to control the high-precision stepper motor to feed the wire, the mechanical transmission selects the precision gear connection, and always maintains the same wire feeding precision and wire feeding speed; the shearing oil cylinder hydraulic station is equipped with a forced air-cooled radiator to double the length of the hydraulic system. The service life of the components; the control system adopts PLC and text display connection, which not only facilitates operation, but also guarantees the stability of the control system. In addition, a preset quantity of production function is designed to control the operation of the whole machine.

Equipment structure principle:

The precision stepper motor drives the feed wheel to rotate, and the PLC and text display replaces the stepper motor controller. The stepper motor ramp-up and slow-down curve and the maximum speed of the stepping motor can be arbitrarily modified as needed to eliminate the impact of the mechanical transmission. Absolutely guarantees that the length of the actual transfer wire is consistent with the theoretical calculation length; when designing the budget, the length of each MM has been divided into 10 pulses, which further ensures the setting of the length accuracy; the adjustable hydraulic cylinder shear can guarantee the circle cut Trimming, cutting time and retracting time can be directly modified on the text display; manual slow feeding and slow feeding are designed, which is easy to operate and reduces material loss.

The working principle of the device:

The equipment selects the subdivision driver to control the high-precision stepper motor to feed the wire, the mechanical transmission selects the precision gear connection, and always maintains the same wire feeding precision and wire feeding speed; the shearing oil cylinder hydraulic station is equipped with a forced air-cooled radiator to double the length of the hydraulic system. The service life of the components; the control system adopts PLC and text display connection, which not only facilitates operation, but also guarantees the stability of the control system. In addition, a preset quantity of production function is designed to control the operation of the whole machine.

Equipment structure principle:

The precision stepper motor drives the feed wheel to rotate, and the PLC and text display replaces the stepper motor controller. The stepper motor ramp-up and slow-down curve and the maximum speed of the stepping motor can be arbitrarily modified as needed to eliminate the impact of the mechanical transmission. Absolutely guarantees that the length of the actual transfer wire is consistent with the theoretical calculation length; when designing the budget, the length of each MM has been divided into 10 pulses, which further ensures the setting of the length accuracy; the adjustable hydraulic cylinder shear can guarantee the circle cut Trimming, cutting time and retracting time can be directly modified on the text display; manual slow feeding and slow feeding are designed, which is easy to operate and reduces material loss.