Pedal Plate Roll Forming Machine

Zhangjiagang City Saibo Science & Technology Co., Ltd.- Type:Rolling Machine

- Forging Forming Method:Mold Forging

- Power Source:Hydraulic Pressure

- Feature:High Efficiency

- Certification:CE

- Warranty:12 Months

Base Info

- Model NO.:Pedal plate

- Customized:Customized

- Advantage:Use Widely

- Condition:New

- Upright Roll Forming Machine:Upright Roll Forming Machine

- Transport Package:No Packing

- Specification:CE SGS

- Trademark:SAIBO

- Origin:Jiangsu, China

- HS Code:84552210

- Production Capacity:300sets,Year

Description

Basic Info.

Model NO. Pedal plate Customized Customized Advantage Use Widely Condition New Upright Roll Forming Machine Upright Roll Forming Machine Transport Package No Packing Specification CE SGS Trademark SAIBO Origin Jiangsu, China HS Code 84552210 Production Capacity 300sets/YearProduct Description

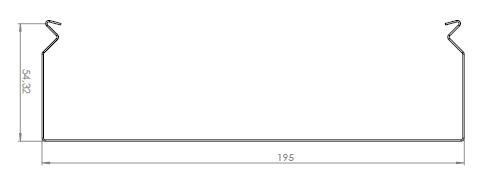

The profile

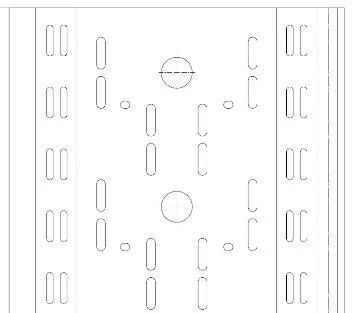

punching

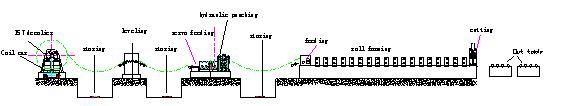

The equipment flow

De-coiler→feeding & leveling→servo feeding & punching→feeding→roll forming→hydraulic cutting & pressing→receiving out table

General structure of equipment

1. De-coiler

Parameter: Width of material: 580mm thickness: 1.25- 2.0mm;

Inner expansion range: 480-560 mm;

The maximal of Diameter: φ 1200mm; The Maximal of loading: ≤ 5T

Motor power: 5.5kw frequency change control

Hydraulic power: 4kw

Press material type: Pneumatic press material

Feeding speed: 0-15m/min, adjustable

2. Leveling machine

A: Working roller: Nine rollers type leveling machine

B: Feature of structure: After the quenching and tempering, chrome-plating processing, the rigidity, surface roughness of the roller etc. Are all enhance greatly; It is composed by the clamping roller and the leveling roller, the clamping roller may the independent control, the leveler has one pair of horizontal guide roller and two pairs of vertical guider roller and easy to adjust by hand wheel. Between the leveler and the feeding device, there is optical sensor, sends out the feedback signal to the control system, the control system sends out the instruction to the frequency conversion motor to change speed, Achieves the uninterrupted level goal.

3. Servo feeding machine

A: Function: Material feeding

B. Feature: Uses the servo motor-driven. Multistage type feeding: The liquid crystal touching screen demonstrated is advantages for the change, establishes various technical parameters. The auto-induction start system and the punch press linkage (control punch press start).

4. Punching machine

Punching machine carrying capacity 125T

Punching machine model: JH-21-125

Punching machine adopt continue punching

Speed: 40 time /MIN

Brand of punching machine: Yang Li

5. Roll forming part

Forming station: 27sets

The maximal coil width: Balance to profiles

The maximal thickness: ≤ 2.0mm

The diameter of the roller axis: ¢ 76mm

Roll mould material: Gcr15, quenching treatment: HRC58-62°

Drive type: 22kw motor, ZQ500 reducer motor

Structure: Wall panel in 20mm

6. Hydraulic cutting

Cutting type: Hydraulic cutting

Hydraulic power: 5.5kw

Material of blade: Cr12, quench treatment, hardness HRC56-58

Quantity: 1

7. Run-out table

Length: 6m

Quantity: 1

| NO. | Name | Quant. | remark |

| 1 | Auto-de-coiler | 1 | 5tons hydraulic decoiler |

| 2 | Leveling machine | 1 | 5.5kw frequency change drive motor, speed adjustable |

| 4 | Servo feeder | 1 | Servo motor drive, 3kw |

| 5 | Punching machine | 1 | 125tons |

| 6 | punching mould | 1 | Material is Cr12mov |

| 7 | Main forming machine | 1 | thickness 1.25-2mm material of roller:GCr 15 |

| 8 | Hydraulic cutting machine | 1 | Required length |

| 9 | Cutting blade | 1 | Cr12 |

| 10 | Run-out table | 1 | With slidecylinders |

| 11 | Electric panel | 1 | PLC control system |