Ridge Cap Roll Forming Machine with Wall Panel Structure

Zhangjiagang City Saibo Science & Technology Co., Ltd.- Type:Rolling Machine

- Forging Forming Method:Mold Forging

- Power Source:Electric

- Feature:High Efficiency

- Certification:ISO9001, CE

- Warranty:12 Months

Base Info

- Model NO.:YX128-345

- Customized:Customized

- Advantage:Easy to Maintenance

- Condition:New

- Product Name:Ridge Cap Roll Forming Machine

- Steel Thickness:0.3-0.8mm

- Decoiler:Manual or Hydraulic

- Transport Package:Sea Packing

- Trademark:SAIBO

- Origin:Jiangsu, China

- HS Code:84552210

- Production Capacity:300set,Year

Description

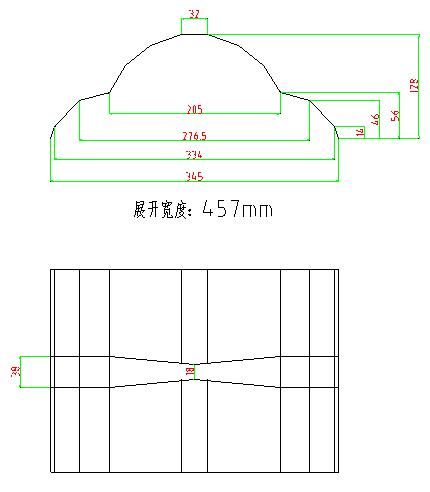

Profile drawing:

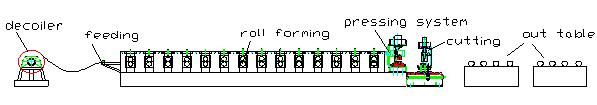

The Chart of Process Flow

Specification of Components

- Width of feeding: 350mm

- Capability: 3 Ton

- Bound of expand &fight: 380mm-520mm

- Mode of expand &fight: inner expand &fight by manual

- Way of feeding: manual

- Roller stations:7stations + 4 station of side roller

- Roller material:ASTM1045 chrome plated surface with chrome

- Shaft diameter: ¢65mm material: SAE1045 with tempering

- Main power: 5.5kw

- Machine structure: wall panel

- To avoid accidents, the machine will be covered with the mobile protective mesh

- Adopt the pre-cutter in order to save the coil

- Adopt the film device in order to protect the coil

- Cutting & pressing after forming: Cut the sheet after roll forming to required length

- Uses two hydraulic cylinders for operation.

- Material of blade/pressing mould:Cr12, 58-62 HRC hardness

- Power by hydraulic,5.5KW

- Tolerance of length: +/- 1.5mm for each piece end product

- Max stacking length :4m

- Power: by air cylinder

- Max stacking thickness:500mm