Gw Carbide-Tungsten Carbide Nozzles for Oil and Gas Industry

Zhuzhou Grewin Tungsten Carbide Tools Co., Ltd.- Certification:ISO9001, ISO, SGS

- Application:Metal Cutting Machine, Metal Processing Machinery Parts, Hardware Spraying Equipment, Wood Spraying Equipment, Plastic Spraying Equipment, Porcelain Spraying Equipment

- Type:High-Performance Low-Pressure Spray Equipment

- Coating:Paint

- Method Type:Manual

- Condition:New

Base Info

- Model NO.:all sizes

- Material:Silicon Carbide, Boron Carbide, Aluminium Jacket

- Tolerance:Ground or Unground

- Various of:High Pressure Airless Spray Equipment

- Performance Grade:Top, Middle

- Usage:Hardware Spraying Equipment

- Quality:Top Quality in China

- Delivery Time:15 Days

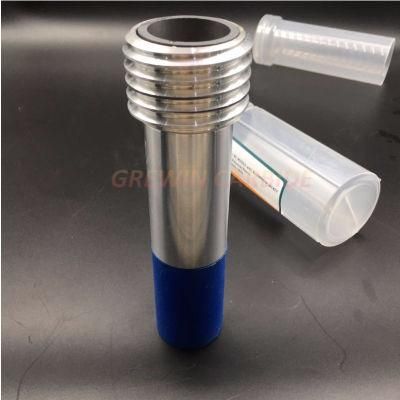

- Packing:Blue Rubber Sleeve

- Shipment:FedEx, DHL, TNT, UPS, EMS, etc.

- Raw Material:100%

- Transport Package:Plastic&Carton

- Specification:customized

- Trademark:GW

- Origin:Zhuzhou Hunan

- HS Code:8207209000

- Production Capacity:100000 PCS Per Month

Description

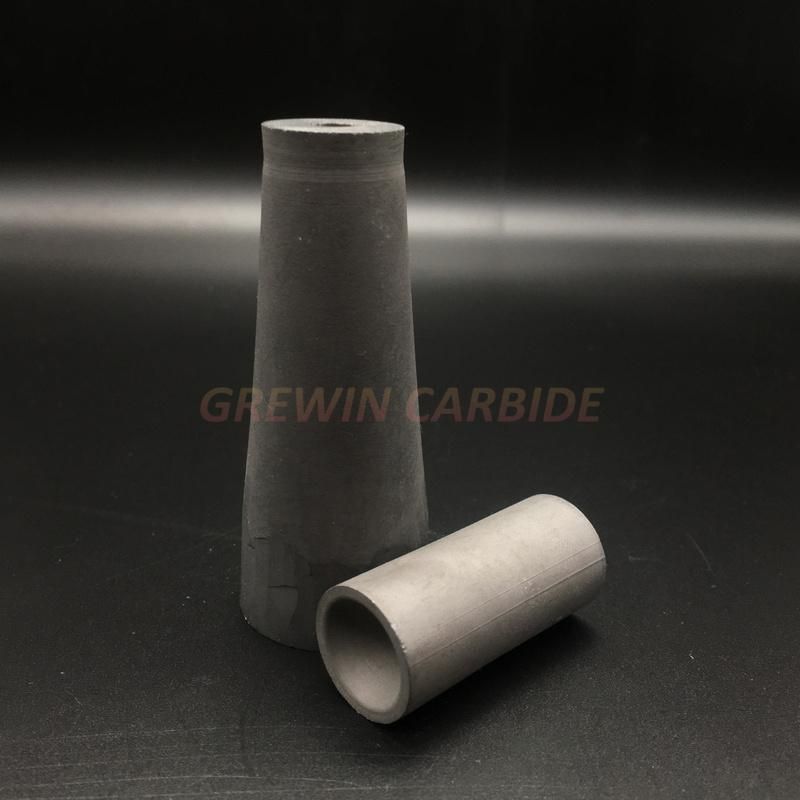

3. Silicon carbide sand blasting nozzles have middle wear resistance and anti-shock ability compared with boron carbide and tungsten carbide, and much lighter than tungsten carbides.

Estimated service life of nozzles(In hours)

Nozzle Material

Steel Grit/Shot

Sand

Aluminum Oxide

Alumina

20-40

10-30

1-4

Tungsten Carbide

500-800

300-400

20-40

Silicon Carbide

600-1000

400-600

50-100

Boron Carbide

1500-2500

750-1500

200-1000

Grewin supply sandblast nozzles with regular types of straight bore and venturI bore, such as boron carbide nozzles, silicon carbide nozzles, tungsten carbide nozzles and ceramic ones.

1. Boron carbide sand blasting nozzles, they have a service life 4-7times of sintered tungsten carbide nozzles, but their shock resistance is not as that of sintered carbide nozzles, so are suitable to serve under wear, stable atmospheric pressure and medium shock.

Specification:

Grind resistant, do not active with acid, low & high temperature resistance,

The density> =2.46g/cm3;

Hardness> =3500kgf/sqm, bending resistance: ≥ 400Mpa

Melting point: 2450degree

And now boron carbide nozzle is instead of hardness alloy, Tungsten carbide nozzle, silicon carbide sandblasting nozzle.

The working life of boron carbide nozzle is 500-1000H

The size can be customized as per drawing

2. sintered tungsten carbide, products including various sand blasting nozzle, high-pressure water spray nozzle, high-pressure water cutting nozzle, bars, sheets, sealing rings, punching die blocks, glass cutters, etc.

We are able to produce tubes with diameter of 200mm and length of 300mm, for rings, size can be diameter up to 320mm and length to be 200mm.

advantages on Tungsten carbide sand blasting nozzles :

1. very high hardness.

2. stable working effort during blasting.

3. long sizes are accetable.

4. very good prices with quite fast delivery.

5. special sizes with drawing are acceptable.