Metal Roofing Galvanized Aluminum Corrugated Steel Sheet Making Colored Wall Roof Panel Cold Roll Forming Machine

Hangzhou Zhongyuan Machinery Factory- Type:Rolling Machine

- Forging Forming Method:Metal Cold Forming

- Power Source:Hydraulic Pressure

- Feature:Automation

- Certification:ISO9001, CE

- Warranty:12 Months

Base Info

- Model NO.:ZYYX

- Customized:Customized

- Advantage:Use Widely

- Condition:New

- Operation Language:English or as Per Client`S Required

- Cutter Material:Cr12 Mould Steel Being Quenched Treatment

- Cutting Style:Cut to Length

- Controlling System:Mitsubishi PLC & Converter

- Guarantee Time:First Year Free, Lifetime Services

- Quality System:ISO9001

- Machine Size:About 16*1.8*1.7m

- Machine Weight:About 16tons

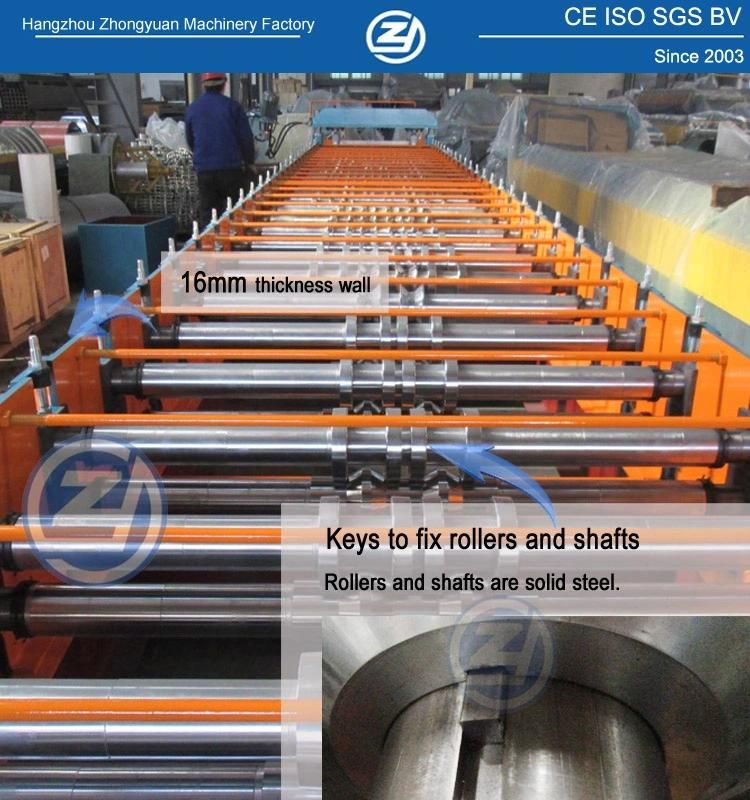

- Rollers Material:No.45 Forged Steel, Plated with Hard Chrom

- Certificate:CE

- Transport Package:1*40gp +1820gp Containers for One Machine

- Specification:CE SGS BV

- Trademark:zhongyuan

- Origin:China

- HS Code:84552210

- Production Capacity:5sets,Month

Description

Decoiler

Decoiler -- Feeding & Guiding -- Pressing--Roll Forming--Hydraulic Cutting - Product to Run Out Table

Packing:

1. 40GP*1+20GP*1 containers for loading one set machine with mechanical decoiler.

2. Main machine body and decoiler is load naked (tighten to container with steel wire rope).

3. Spare parts and operating tools are loading in tooling box.

Delivery : about 70 days

Controller:

We choose Mitsubishi PLC from Japan.

The PLC controller is the "CPU" of forming machine. Machine excellence performance need the supports of excellence PLC.

With touch screen mode, let your workers enjoy the easy operation; with auto working mode, let your workers free their hands!

About us

1. Customize roll forming machines since 2003.

2. Capacity: 12-15 sets/month

3. Delivery: in only 5-8 weeks for urgent order

4. Company occupies 6650, in which 5650 for workshops

5. Have our own tool center. 12 sets CNC machines.

6. Technician can be sent to your factory to install the machine and train your workers

7. Zhongyuan is a "All-in-house source"

--from raw material to the final high-precision forming machine. We have our precise tooling center.

Get Free:

profile drawing & machine design technical support by our 15 year experience technicians!