Continuous Rolling Mill Mandrel for Pipes and Tubes Mill Tools

Yantai Fangle Metallurgy Group Co., Ltd.- Condition:New

- Certification:CE, ISO9001

- Standard:DIN, ASTM, GB

- Customized:Customized

- Material:Alloy

- Application:Metal Processing Machinery Parts

Base Info

- Model NO.:as the drawing

- Application Range:Continuous Rolling Mill,Mpm,Fqm,Pqf

- Transport Package:Woodern Case

- Specification:max 20m, Diameter 100mm-500mm

- Trademark:FANGLE

- Origin:China

- Production Capacity:50000tons,Year

Description

Products Parameters

| Materials | AISI H13, X35CrMo V51 ,4CrMoSi V1,28NiCrMoV10 etc. |

| Diameter | 80-600mm |

| Length | max to 20,000mm |

| Hardness | Meet the customers' requirements |

| Surface Processing | Chrome plating |

| Threading | Available, phosphating |

| Chrome plating | As per requirement,thickness 0.045-0.065mm |

| Process | EBT + LF (VD) + ESR |

| Property tests | Magnetic testing,Ultrasonic testing etc. |

| Lead time | about 45 days |

| Delivery condition | Finished machining |

| Application | MPM, PQF and FQM mills,Assel Mills,Accu-roll mill, Push Bench, Pilger mill,continuous tube mill etc |

| Market | India,Saudi Arab,Russia,Slovenia,Thailand,Vietnam etc. |

Production process control

1.Steel manufacturing

The steel shall be produced by the electric arc furnace and has to be vacuum degassed. Hydrogen must be held below 2.5 ppm and Oxygen below 30 ppm.

2. Hot Forming. The mandrel bars are to be forged from an ingot. The cross-sectional area of the solid forging shall have a reduction by hot forming from that of the ingot in the ratio of not less than 8 to 1. There should not have any defects.

3. Heat Treatment. The hot forming process shall be immediately followed by heat treating processes. .Material must ensure the required structure and mechanical properties.

4.Mandrel tests.

4.1 Mechanical properties

4.2 Tensile and impact tests

Tensile strength

Yield strength

Elongation:

Reduction of area

Charpy V-Notch impact test: testing at room temperature.

Charpy tests will be in transverse orientations.

4.3 Hardness tests

4.4 Microscopically Examinations

4.5 Microstructure after Heat Treatment

4.6 Austenitic Grain Size

4.7 Nonmetallic Inclusion Contents

4.8 Non destructive Tests

5. Straightness

6.Machining

7.Chrome plating

8. Marking

9.Protection and Packing

10.Certification

Mandrel products show

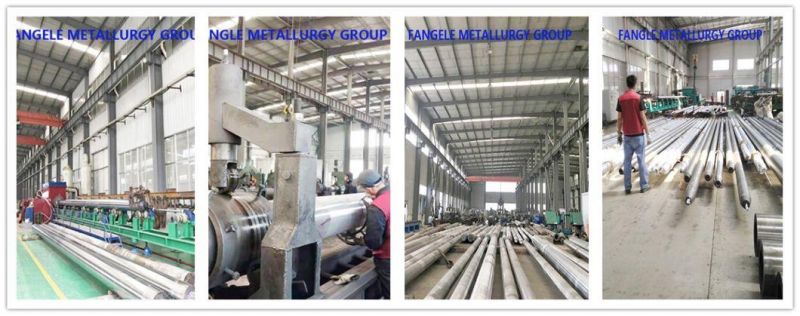

Mandrel Workshop show

Customer Visit