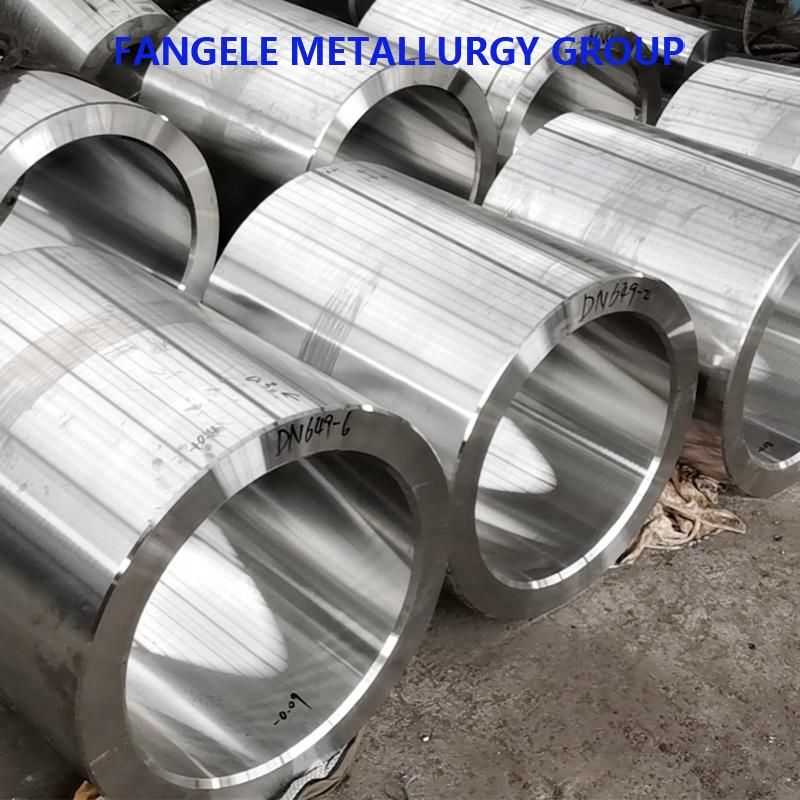

Centrifugal Casting Steel Sleeve for Cold Rolling Mill Tool

Yantai Fangle Metallurgy Group Co., Ltd.- Condition:New

- Certification:CE, ISO9001

- Standard:DIN, ASTM, GB

- Customized:Customized

- Material:Alloy

- Application:Metal Processing Machinery Parts

Base Info

- Model NO.:as the drawing

- Application Range:Aluminum Foils,Plates and Stainless Foils&Plates

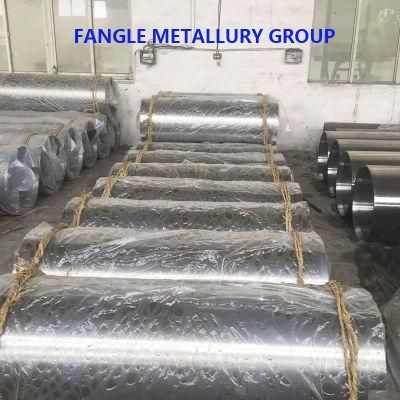

- Transport Package:Seaworthy Package

- Specification:as the requirement

- Trademark:FANGLE

- Origin:China

- Production Capacity:50000tons,Year

Description

Basic Info.

Model NO. as the drawing Application Range Aluminum Foils,Plates and Stainless Foils&Plates Transport Package Seaworthy Package Specification as the requirement Trademark FANGLE Origin China Production Capacity 50000tons/YearProduct Description

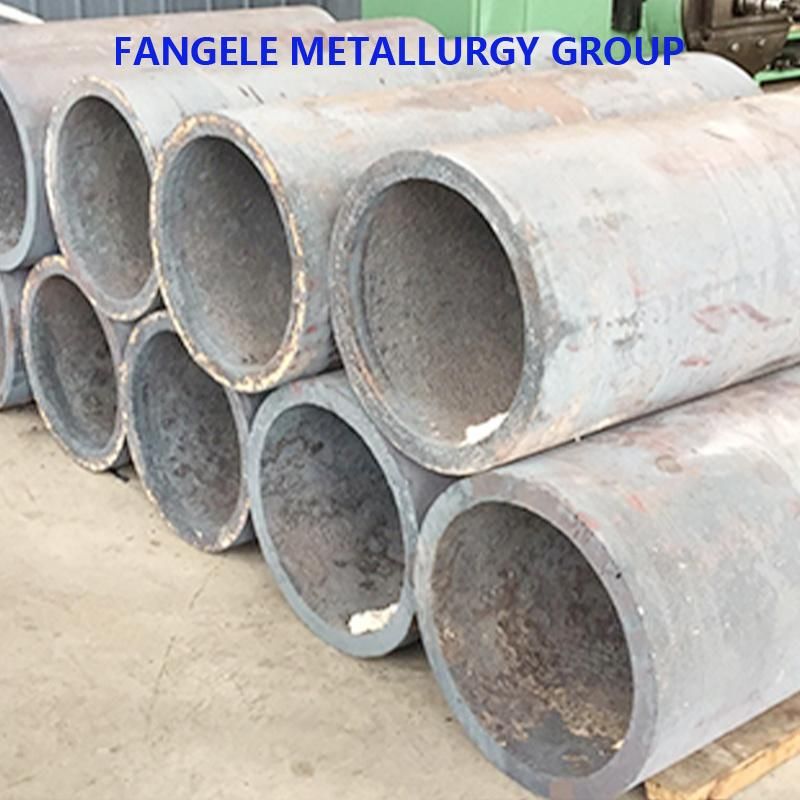

Centrifugal casting steel sleeveDescription

Centrifugal casting steel sleeve is the tool used for cold rolling mill. The centrifugal casting process is dedicated to ensure internal and external surfaces of sleeve have no defects such as crack, slag, blowhole, blister, etc. The heat treatment process will make sure the mechanical performance of sleeve. With the special machining tool and rational process the sleeves have high performance of concentricity, cylindrical, symmetry and balancing.

Performance:

| Materail | strength of extension(MPa) | Yield strength(MPa) | ductility(%) | hardness(HB) |

| ZG310-570 | 570 | 310 | ≥ 17 | 217-255 |

| 35CrMo | ≥985 | ≥835 | ≥ 12 | ≥229 |

| 35CrMoV | ≥1080 | ≥930 | ≥ 10 | ≥240 |

| 35NiCrMo | ≥830 | ≥660 | ≥ 8 | ≥240 |

| KCP-12 | ≥1080 | ≥835 | ≥ 8 | 240-260 |

Chemical material:

| Material | C | Si | Mn | Cr | Ni | Mo | V | S,P | illustration |

ZG310 -570 | 0.50 | 0.60 | 0.90 | <=0.040 | Low plasticity and toughness, poor high temperature resistance, Low purchasing cost | ||||

35CrMo | 0.32 - 0.40 | 0.17 - 0.37 | 0.40 - 0.70 | 0.80 - 1.1 | 0.15 - 0.25 | ≤0.035 | General high temperature resistance Low purchasing cost | ||

35CrMoV | 0.30 - 0.38 | 0.17 - 0.37 | 0.40 - 0.70 | 1.00 - 1.30 | 0.20 - 0.30 | 0.10 - 0.20 | ≤0.035 | Can meet the general use requirements, Economical purchasing cost | |

35NiCrMo | 0.30 - 0.37 | 0.60 - 0.90 | 0.70 - 1.00 | 0.40 - 0.90 | 0.60 - 0.90 | 0.40 - 0.50 | <=0.035 | High strength and toughness , good high temperature resistance, high purchasing cost |

Heat treatment

Quenching process: Pit quenched with water quenching and oil cooling.