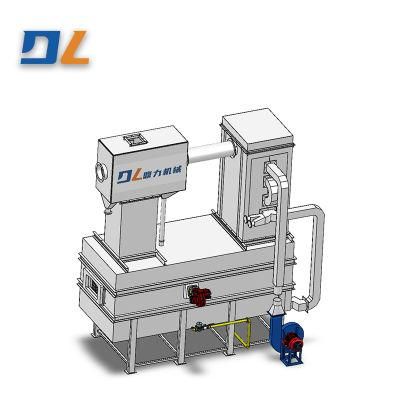

Foundry Coated Sand Recycling Roaster

Qingdao Ding Li Machinery Co., Ltd.- After-sales Service:Aftersale Service Provided

- Warranty:One Year Warranty,

- Control Type:PLC

- Customized:Customized

- Condition:New

- Automatic Grade:Automatic

Base Info

- Model NO.:S5815

- Certification:CE, RoHS, GS, ISO9001

- Type:Sand Casting

- Transport Package:National Standard or Customized

- Specification:According to equipment

- Trademark:DL

- Origin:Qingdao, China

- HS Code:8474802000

- Production Capacity:700

Description

Basic Info.

Model NO. S5815 Certification CE, RoHS, GS, ISO9001 Type Sand Casting Transport Package National Standard or Customized Specification According to equipment Trademark DL Origin Qingdao, China HS Code 8474802000 Production Capacity 700Product Description

The coated sand roasting furnace body is provided with a combustion chamber, and an igniter facing the combustion chamber is installed on the body, including a feed chamber fixed on the upper side of the body, the upper side of the combustion chamber is communicated with the feed chamber, and the combustion chamber is far away from the feed One side of the chamber is communicated with a waste heat pack, and the waste heat pack is communicated with a waste gas pipe; a baffle is arranged in the feed chamber, and a preheating passage connected with the waste gas pipe is opened in the side wall of the feed chamber; the preheating chamber is communicated with the waste gas pipe . , the exhaust gas discharged from the combustion chamber is sent into the feed chamber to preheat the sand particles, and the sand particles with a certain temperature enter the combustion chamber, which can reduce the consumption of heat in the combustion chamber, thereby reducing the use of natural gas and reducing the roasting cost of sand particles.

The coated sand roasting furnace body is provided with a combustion chamber, and an igniter facing the combustion chamber is installed on the body, including a feed chamber fixed on the upper side of the body, the upper side of the combustion chamber is communicated with the feed chamber, and the combustion chamber is far away from the feed One side of the chamber is communicated with a waste heat pack, and the waste heat pack is communicated with a waste gas pipe; a baffle is arranged in the feed chamber, and a preheating passage connected with the waste gas pipe is opened in the side wall of the feed chamber; the preheating chamber is communicated with the waste gas pipe . , the exhaust gas discharged from the combustion chamber is sent into the feed chamber to preheat the sand particles, and the sand particles with a certain temperature enter the combustion chamber, which can reduce the consumption of heat in the combustion chamber, thereby reducing the use of natural gas and reducing the roasting cost of sand particles.| productivity(t/h) | 2-3 |

FAQ:

FAQ:Q1. Where is your factory? How can I visit it?

A : Our factory is located in Qingdao City, Shandong Province, China. You can fly to Qingdao Jiaodong Airport and we will pick you up.

Q2. Do you produce machine specific parameters according to samples?

A: Yes, we produce the machine you want according to your sample or technical drawing. Usually a machine has different sizes and technical requirements, such as sand mixing equipment, screening equipment, cooling equipment, etc.

Q3. What is your sample service?

A: If we have the ready-made machine, we can provide the sample test that the customer wants to produce, but the customer must pay the sample shipping cost.

Q4. What is the MOQ for your machine?

A: Usually our MOQ is 1 set.

Q5. Do you test all machines before delivery?

A: Yes, we do 100% testing before delivery.

Q6: How do you keep our business in a good long-term relationship?

Answer: 1. We maintain good quality and competitive prices to ensure our customers benefit;

2. We respect every customer as our friend, we sincerely do business with them and make friends,

no matter where they come from.

Qingdao Dingli Machinery Co., Ltd.

Qingdao Dingli Machinery Co., Ltd.1. We are one of the manufacturers of metal casting machinery in China.

2. We produce clay sand processing equipment, resin sand recovery equipment, coated sand making equipment, coated sand regeneration equipment, sand drying equipment, dust removal equipment, conveying equipment, cooling equipment, magnetic separation equipment, screening equipment, mixing equipment Sand machine, etc.

3. Our machines are widely used to produce and process casting parts, metal castings, plumbing fittings, auto parts, brass, aluminum, zinc, cast iron production line valves, etc. Please contact us!

4.We have professional technical support and after-sales service. Has the whole line of casting machines, good quality, reasonable price and fashionable design.

Qingdao Dingli Machinery Co., Ltd. is an enterprise specializing in the production of foundry machinery and equipment. It mainly produces foundry clay sand, resin sand, coated sand, wet sand drying, lost foam, and water glass sand processing equipment. It can undertake various mechanized sand processing equipment. Design, manufacture, installation, commissioning and other turnkey projects. The factory has strong technical force and excellent process equipment. It has a long-term close technical cooperation relationship with senior experts and scholars from many domestic universities and scientific research institutions, and can provide users with excellent performance, reliable products and satisfactory services.

The company takes science and technology to develop the enterprise, quality is the foundation, continuous improvement, and customer satisfaction is the purpose.

The company mainly undertakes the following projects:

20-180t/h mechanized clay sand sand processing production line turnkey project and stand-alone supporting equipment.

The annual output of 1000-20000t castings condensed resin sand mechanized production line is a turnkey project and stand-alone supporting equipment.

The annual output of 3000-10000t thermal coated sand making equipment is a turnkey project and stand-alone supporting equipment.

The annual output is 3000-7000t thermal coated sand regeneration complete equipment turnkey project and stand-alone supporting equipment.

5-15t/h water glass mechanized production line turnkey project and stand-alone supporting equipment.

5-30t/h three-pass sand drying equipment turnkey project and stand-alone supporting equipment.

5-40t/h lost foam complete set of equipment turnkey project and stand-alone supporting equipment.

Various types of clay sand horizontal molding machines and vertical molding machines.

Various types of shot blasting equipment, lifting equipment, conveying equipment, cooling equipment, magnetic separation equipment, environmental protection dust removal equipment.