Aluminum Profile Commercial Powder Coating Machine

Colo International Corporation Group Ltd.- After-sales Service:Online

- Warranty:1 Year

- Type:Powder Coating, Powder Coating Booth

- Coating:Powder Coating

- Substrate:Steel

- Certification:CE, CE,ISO

Base Info

- Model NO.:colo-line 1

- Condition:New

- Brand Name:Colo

- Size:Custom-Made

- Voltage:110V,380V

- Transport Package:Wodden Case

- Specification:CE

- Trademark:COLO

- Origin:Hangzhou. China

- HS Code:8424899990

- Production Capacity:30PCS

Description

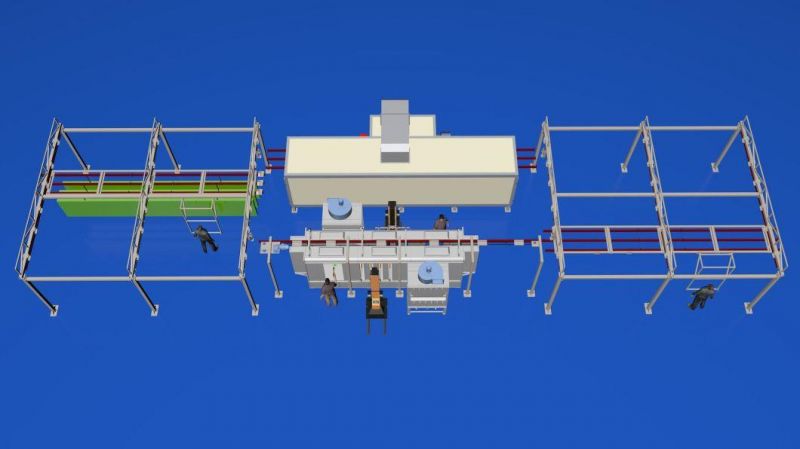

COLO Top Track Powder Coating Oven

COLO Top Track Powder Coating Oven1. The powder coating oven can be heated by gas, diesel, or electric heating as actual requirements.

2. High efficiency heating element enables rapidly raise to the required temperature, save your time every day.

3. A powerful circulation fan makes uniform hot airflow in inner chamber ensure high quality curing results.

4. Construced with 100mm thickness rock wool board, ensures minium temperature dropping.

5. PLC control system provides an easy and accurate heating process, digitally setting the heating time and temperature.

COLO-0825 Automatic Powder Spray Booth1.This tunnel powder coating booth has 2 working station allows parts recieving coating from both side, parts enter the booth from one entrance and exit from the other through conveyors,

2. Powder reclaim is achieved by a recovery stage, which is combined with several pieces of high precision filters, reach 98% powder recycling rate.

3. Filter cleaning is automatically done through pulse solenoid valves, thus filter life is extended.

4. PLC provides all the functions you need, control the fan working, set interval and time of pulse jet for filter cleaning.

Automatic Reciprocating Powder Coating System

Automatic Reciprocating Powder Coating SystemConfigurations and Features

1. It is the ideal entry into automatic series production offering quality finishes and great powder savings.

2. Multi controllers of automatic powder coating gun installed on a central cabinet, with compact design and simple operation.

3. The cabinet can be tailored to customer's demands, allows to install Max. 24 control units.

4. Cl-191S automatic powder coating machine is one of the most suitable solution for coating line, effective, relible, cost-saving.

5. The reciprocator driven by frequency motor, speed and stroke adjustable. The sturdy construction could adapt to continual load everyday.

| conveyor trolley : | 500kg loading |

| curing oven size: | L5.8x W1.8x H2m |

| Heating method: | GAS with 100000 Kcal burner |

| Spray booth size: | L6 x W1.8 x H2m |

| Fan motor | 3kw,380V 3phase 50Hz |

| Total power | 50kw,380V 3phase 50Hz |

Specification:

1.Spray booth:

Inner size: L6 x W1.8 x H2m

Booth board: SPCC/= 1.5mm Bending and forming

Under frame:4 # square tube

booth bottom:with removable hoppers

2.curing oven

inner Size :L5.8x W1.8x H2m

Warm board: Thickness 100mm, edge SPGCC t=1.5mm

Burner of oven: 100,000 Kcal ,1 pcs (Riello)

fan motor: 3KW 1pcs,

3.spray gun:automatic spray gun 8pcs+2pcs manual spray gun

NOTES

Listing and specifications are provisional and subject to change without notice for improvements or updates.

Director: Oven and spray booth powder galvanized steel structure and painted steel conveyor

Rock wool insulation with a thickness of 150 mm and a density of 100 kg m3. SAV; Supply of spare parts

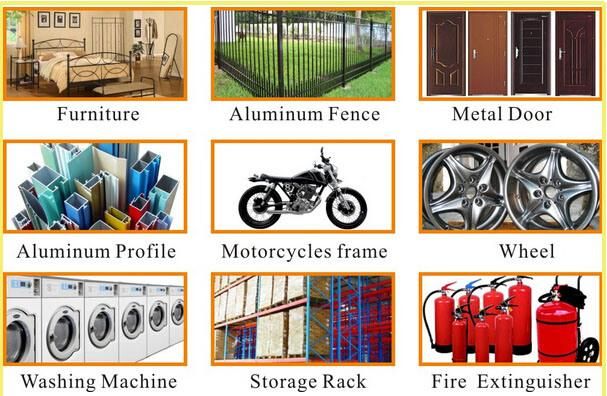

APPLICATIONS

Loading form our factory

Factory details

Any question,feel free to send your email.