Standing Seam Roof Forming Machine with Straight and Tapered Type

Xiamen Xinhonghua Machinery Co., Ltd.- Type:Hydraulic Machine

- Forging Forming Method:Tire Mold Forging

- Power Source:Hydraulic Pressure

- Feature:Automation

- Certification:SGS

- Warranty:12 Months

Base Info

- Model NO.:YX65-400-425

- Customized:Customized

- Advantage:Use Widely

- Condition:New

- Size:5800*1600*1500mm

- Weight:7000kgs

- Motor Power:7.5kw*2 Sets

- Hydraulic Power:2.2kw

- Forming Steps:13

- Effective Width:300mm,400mm,500mm

- Material Width:470mm,575mm,680mm

- Material Thickness:0.4-1.0mm

- Working Speed:8-14m,Min

- Voltage:380V,60Hz,3pH

- Transport Package:Standard Package for Export

- Specification:SGS

- Trademark:XHH

- Origin:Xiamen Port, China

- HS Code:84552290

- Production Capacity:20 Sets,Months

Description

Basic Info.

Model NO. YX65-400-425 Customized Customized Advantage Use Widely Condition New Size 5800*1600*1500mm Weight 7000kgs Motor Power 7.5kw*2 Sets Hydraulic Power 2.2kw Forming Steps 13 Effective Width 300mm,400mm,500mm Material Width 470mm,575mm,680mm Material Thickness 0.4-1.0mm Working Speed 8-14m/Min Voltage 380V/60Hz/3pH Transport Package Standard Package for Export Specification SGS Trademark XHH Origin Xiamen Port, China HS Code 84552290 Production Capacity 20 Sets/MonthsProduct Description

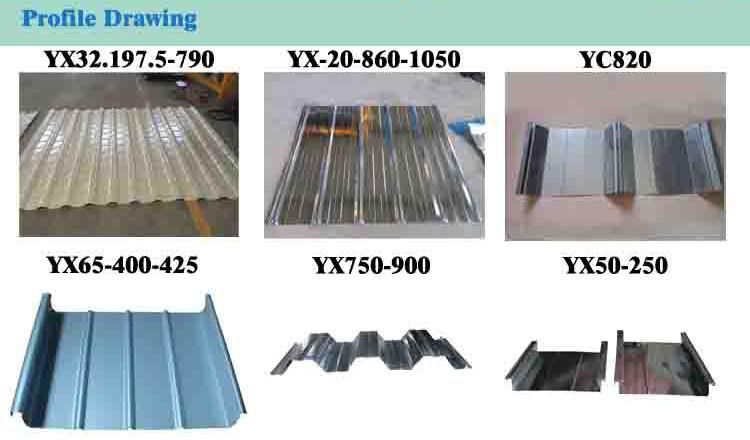

Detail information of YX65-400-425 Standing Seam Roof Forming Machine with Straight and Tapered type are as follow:

1,Main Technic Data:

1. | Size | 6500*1600*1500mm |

| 2. | Weight | 70000KGS |

| 3. | Motor Power | 7.5KW*2 sets |

| 4. | Hydraulic Power | 2.2KW |

| 5. | Voltage | 380V/60HZ/3PH |

| 6. | Forming Steps | 13 |

| 7. | Forming Speed | 8-14m/min |

| 8. | Effective Width | 300mm, 400mm, 500mm |

| 9. | Material of Width | 470mm, 575mm, 680mm |

| 10. | Thickness for Aluminum sheets: | 0.4-1.0mm |

| 11. | Thickness for Colored Prepainted and Galvanized Sheet | 0.4-0.8mm |

| 12. | Material for All Rollers | high grade no. 45 forged steel, plated hard chrome on the surface of rollers |

2,Main Accessories:

(1) Main Forming Machine,

(2) 5 Tons Manual Uncoiler,

(3) PLC Computer Controlling System With Touching Screen,

(4) Hydraulic System,

(5) Hydraulic Forming Cutter,

(6) 3 Run Out Tables,

(7) Operation Instruction,

(8) Tool.