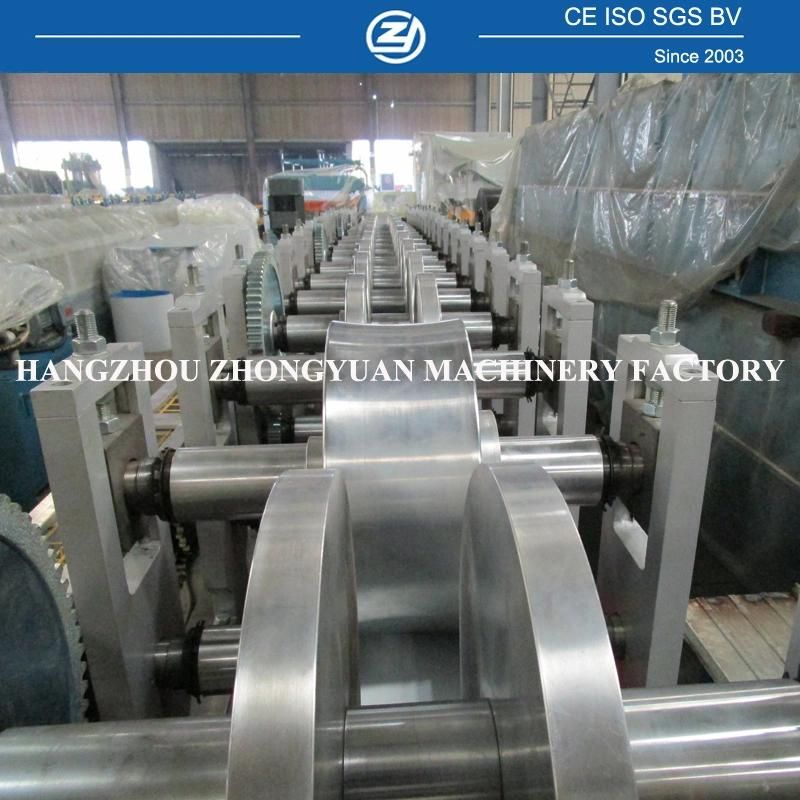

Reliable and Good Steel Roof Gutters Roll Forming Machine

Hangzhou Zhongyuan Machinery Factory- Type:Rolling Machine

- Forging Forming Method:Cold Roll Forming

- Power Source:Electric

- Feature:Automation

- Certification:ISO9001, CE

- Warranty:24 Months

Base Info

- Model NO.:ZYYX

- Customized:Customized

- Advantage:Easy to Maintenance

- Condition:New

- Certificate:ISO,Ce,Soncap

- Coil Width:450mm

- Main Motor Power:5.5kw

- Electric Condition:440,3phase,60Hz

- Size:9960*800*1800mm

- Operation Language:English or as Per Client`S Required

- Shaft Diameter:72mm

- Controlling System:Mitsubishi PLC & Converter

- Transport Package:40gp Container for One Machine

- Specification:CE SGS BV

- Trademark:zhongyuan

- Origin:China

- HS Code:84552210

- Production Capacity:10sets,Month

Description

Components of machine

Process flow:

Decoiler -- Feeding & Guiding -- Roll Forming-- Hydraulic Cutting - Product to Run Out Table

Why choose this machine?

1. Certificate: ISO 9001, CE,

2. Lifetime seivices

3. 72mm diameter solid steel shaft. Roller cover with 0.05mm chrome; Lifetime>10years.

4. Introduced Mitsubishi PLC with touch screen to machine controll system.

5. One worker operation (minimum)

6. Heat treatment:Cutting blade. Quenched treatment: Cr12 mould steel cutter

7. Product cut-to-length.

8.Technician overseas installing and training available

Controller:

Controller is the "CPU" of forming machine. We choose Mitsubishi PLC from Japan.

With touch screen mode, let your workers enjoy the easy operation;

With auto working mode, let your workers free their hands!

About us

We are professional in making roll forming machines since 2003. Company occupies 6650, in which 5650 for workshops.

1. Capacity: 12-15 sets/month

2. Delivery: in only 5-8 weeks for urgent order

3. Have our own tool center. 12 sets CNC machines.

4. Zhongyuan is a "All-in-house source"

--from raw material to the final high-precision forming machine. We have our precise tooling center.

5. You can rely on our team!

We have engineers with experience more than 15 years in metal forming industry.

Get Free:

"Send" below get profile drawing & design technical support by our 15 year experience technicians FOR FREE!