Dlc Anti Crack Hard Golf Parts Gold Film Waterproof Nano Coating Machine

Ningbo Danko Vacuum Technology Co., Ltd.- Type:Ion Arc Coating Machine

- Coating:Vacuum Coating

- Substrate:Tools, Moulds

- Certification:CE, ISO, TUV

- Condition:New

- Machine:PVD Vacuum Coating Machine for Improving Function

Base Info

- Model NO.:DK

- Weight:5t

- Business Type:Manufacturer

- Coating Filml:Function Film

- After Sales Service:Engineer Available to Service on Site

- Other Service:24h, Remote Guidance

- Application:Tools and Moulds

- Film Color:Golden, Dlc, Silver, and So on

- Structure Type:Vertical or Horizantal Type

- Controlling System:PLC Touching Screen

- Transport Package:Wood Case, Container

- Specification:1600*1500

- Trademark:DANKO

- Origin:Ningbo, China

- HS Code:8479899990

- Production Capacity:1000sets , Year

Description

Basic Info.

Model NO. DK Weight 5t Business Type Manufacturer Coating Filml Function Film After Sales Service Engineer Available to Service on Site Other Service 24h, Remote Guidance Application Tools and Moulds Film Color Golden, Dlc, Silver, and So on Structure Type Vertical or Horizantal Type Controlling System PLC Touching Screen Transport Package Wood Case, Container Specification 1600*1500 Trademark DANKO Origin Ningbo, China HS Code 8479899990 Production Capacity 1000sets / YearProduct Description

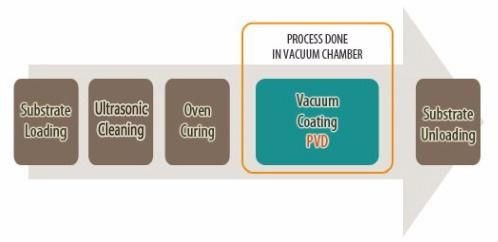

DLC anti crack hard golf parts gold film waterproof nano coating machine[PVD] Physical Vapor Deposition: Vacuum deposition methods which can be used to deposit thin films and coatings.

Description

DankoVAC- Tools PVD Thin Film Deposition Vacuum Coating Machine is high performing and easy operating, equipped with arc sputtering system. This machine offers a wide range of application, such as hard film coating, abrasion resistance coating and exterior coating on tools of cutting, stamping, molding and metal die-casting, with DLC (diamond like coating) function to improve the hardness.

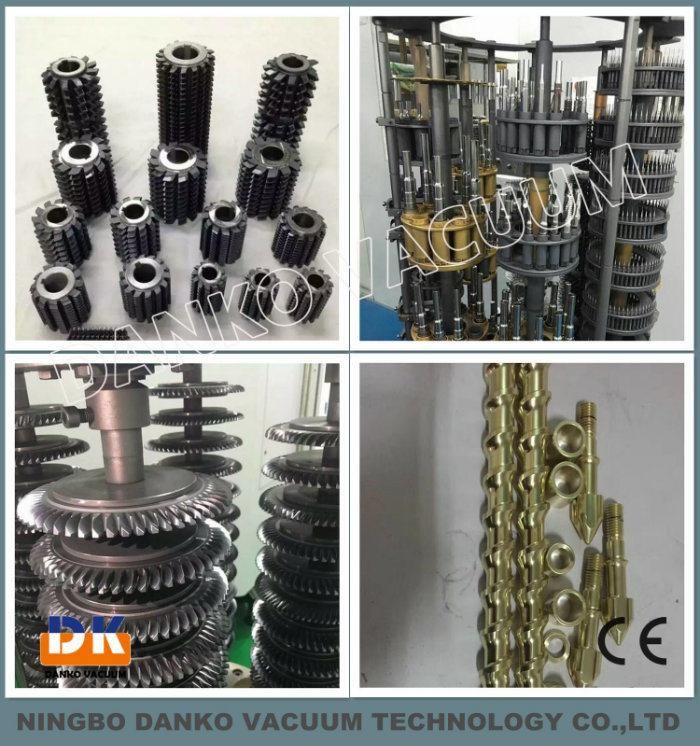

Substrate Material: tools, cutter and mould

Recommend Machine: Multi Arc Ion Coating Machine

Structure Type: Vertical structure, #304 Stainless Steel

A. Coating Film: Multi-functional metal film, hard film, DLC film

B. Film Color: multi colors, gun black, titanium golden color, rose golden color, stainless steel color, purple color and other more colors

C. Film type: TiN, TiC, CrN, ZrN, TiCN, TiCrN, TiNC, TiALN and DLC

D. Consumables in production: Titanium, Chromium, Zirconium

Process

Application

A. Precision mould industry: dies, shear mould, standard mould and other moulds

B. Tool industry: drill, hard alloy, milling cutter, broaches, screw tap, screw fastener and gear cutter

C. Automobile industry: piston, piston rings and alloy wheels.

Advantages

High deposition speed

High adhesion

Good Uniformity

Pollution Free

Easy operation

Energy saving

Customized processing services

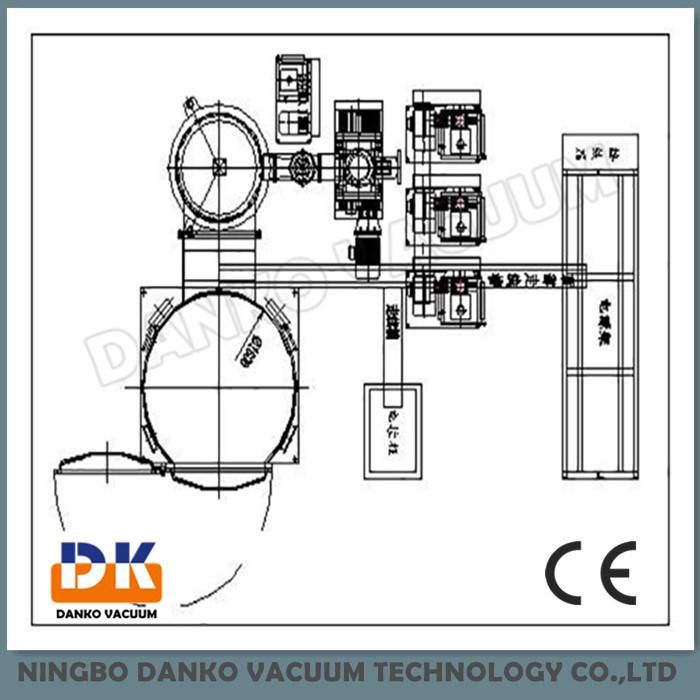

Configurations

A. Pumps:

mechanical pump + roots pump + diffusion pump + holding pump (or optional: cryogenic pump, cryogenic pump system)

B. Gas System: 1~4 path

C. Limited Vacuum: 6*10-4 pa (cleanroom, no-loading)

D. Arc Source : 4-18sets (according to different machine size)

E. Power Sources: DC power supply, Medium frequency power supply, medium frequency power supply, heater supply, activation power supply, pulsed bias voltage power supply

F. Targets: DC Magnetic Target, Medium Twin Target, Plane Target

H. Gas Time : 5*10-4 pa, within 30mins

I. Controlled by Manual, Semi-automatic, Full automatic, PLC

Workshop

For more details on configurations quotations, please contact us.

Ningbo Danko Vacuum Technology Co.,Ltd

https://dankovac.en.made-in-china.com

Sara