Reducer Roller for Pipe Sizing and Reducing Process During Seamless Steel Pipes and Tubes Production

Yantai Fangle Metallurgy Group Co., Ltd.- Condition:New

- Certification:CE, ISO9001

- Standard:DIN, ASTM, GB

- Customized:Customized

- Material:Alloy

- Application:Metal Processing Machinery Parts

Base Info

- Model NO.:as the drawing

- Application Range:Sizing Machine

- Transport Package:Woodern Case

- Specification:as the drawing

- Trademark:FANGLE

- Origin:China

- Production Capacity:50000 Tons,Year

Description

Basic Info.

Model NO. as the drawing Application Range Sizing Machine Transport Package Woodern Case Specification as the drawing Trademark FANGLE Origin China Production Capacity 50000 Tons/YearProduct Description

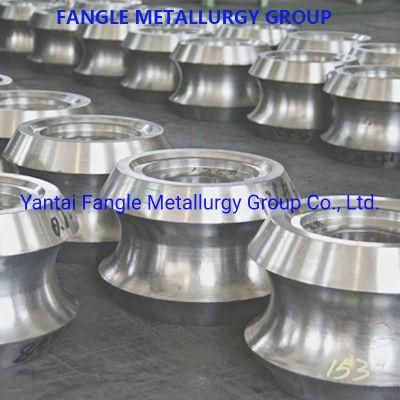

Reducer Roller for Pipe Sizing and Reducing Process during seamless steel pipes and tubes productionDescription

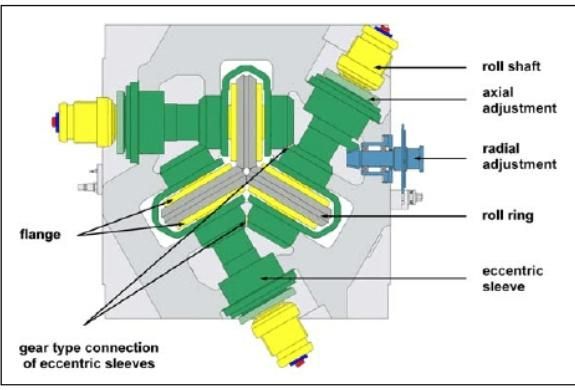

Reducer roll is the important tool for pipe sizing and reduing used on the three-rolled stretch reducing mill (SRM) stands.The purpose of sizing is to make the steel tube into the required accurate size and roundness , and to further improve the quality of the outer surface of the steel tube.

After sizing, the steel tube has smaller diameter deviation, smaller ellipticity, better straightness and smooth surface.

Steel Grade: Casting steel

Production process :

·Casting

·rough machining

·heating treatment

·finishing

·Package

Quality Assurance :

·MT and Size report will be supplied .

Application

Stretch Reducing Mill stands, that is SRM stand.

Products show

Customer Visit