Mandrel Used for The Continuous Mandrel Rolling Process and The Push Bench Process

Yantai Fangle Metallurgy Group Co., Ltd.- Condition:New

- Certification:CE, ISO9001

- Standard:DIN, ASTM, GB

- Customized:Customized

- Material:Alloy

- Application:Metal Processing Machinery Parts

Base Info

- Model NO.:as the drawing

- Application Range:Continuous Rolling Mill,Mpm,Fqm,Pqf

- Transport Package:Woodern Case

- Specification:max 20m, Diameter 100mm-500mm

- Trademark:FANGLE

- Origin:China

- Production Capacity:50000tons,Year

Description

Basic Info.

Model NO. as the drawing Application Range Continuous Rolling Mill,Mpm,Fqm,Pqf Transport Package Woodern Case Specification max 20m, Diameter 100mm-500mm Trademark FANGLE Origin China Production Capacity 50000tons/YearProduct Description

mandrel used for the continuous mandrel rolling process and the push bench processDescription

Mandrel plays a very important role in the continuous mandrel rolling process and push bench process. Continuous rolling mill mandrel (CRM mandrel) or MPM & PQF mandrel bar are also named retained mandrels.Mandrel bars are the key parts during the production of Seamless Tubes and Pipes. Once the billet has been pierced, the Mandrel Bar supports the tube internally during elongation and wall thickness reduction.

The Mandrel bar is the important tool for multi-stand pipe mill process,which is also called Mannesmann plug mill process or multi-stand plug mill.In the Mandrel Mill Process, a solid round (billet) is used. It is heated in a rotary hearth heating furnace and then pierced by a piercer. The pierced billet or hollow shell is rolled by a mandrel mill to reduce the outside diameter and wall thickness which forms a multiple length mother tube. The mother tube is reheated and further reduced to specified dimensions by the stretch reducer. The tube is then cooled, cut, straightened and subjected to finishing and inspection processes before shipment.

The continuous mandrel rolling process and the push bench process in the size range from approx. 21 to 178 mm outside diameter.

Production process:

1) forging or rolled

2) rough machining

3) magnetic test

4) heating treatment

5) ultrasonic test

6) finish machining

7) chromium plating

8) thread phosphating

9) package

Production parameters

| Materials | AISI H13, X35CrMo V51 ,4CrMoSi V1,28NiCrMoV10 etc. |

| Diameter | 50-600mm |

| Length | max to 20,000mm |

| Hardness | Meet the customers' requirements |

| Surface Processing | Chrome plating |

| Threading | Available, phosphating |

| Chrome plating | As per requirement,thickness 0.045-0.065mm |

| Process | EBT + LF (VD) + ESR |

| Property tests | Magnetic testing,Ultrasonic testing etc. |

| Lead time | about 45 days |

| Delivery condition | Finished machining |

| Application | MPM, PQF and FQM mills,Assel Mills,Accu-roll mill, Push Bench, Pilger mill,continuous tube mill etc |

| Market | India,Saudi Arab,Russia,Slovenia,Thailand,Vietnam etc. |

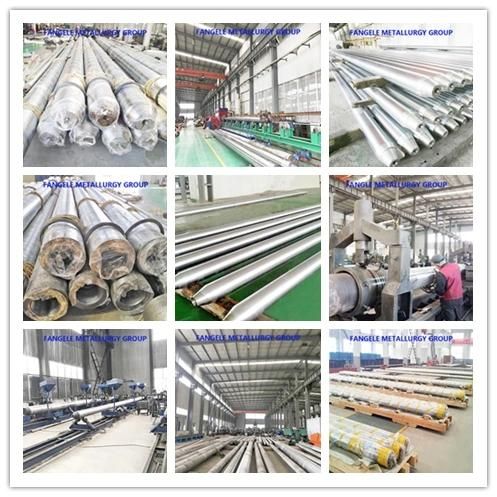

Mandrel products show

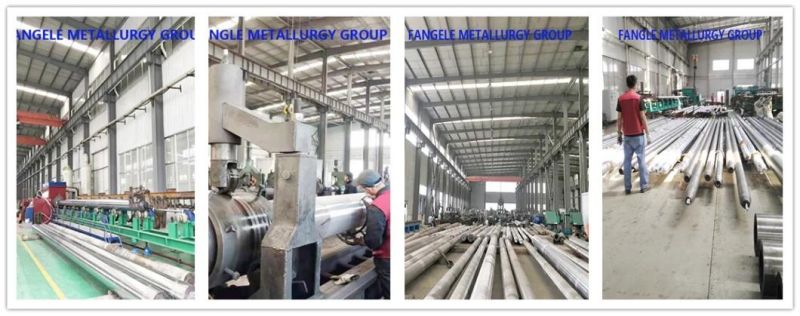

Mandrel Workshop show

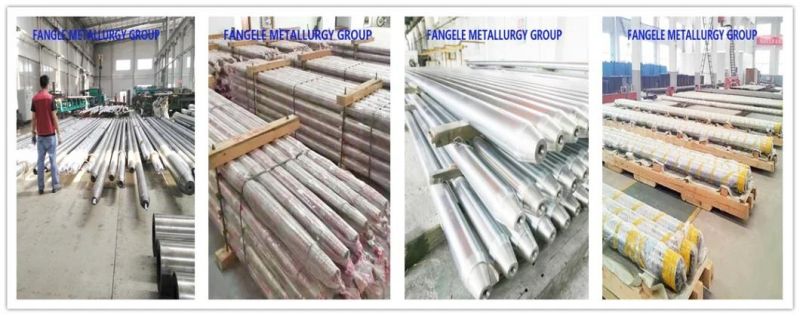

Package &Delivery

Customer Visit