Chromium Plating Mandrel Used for Producing Seamless Steel Pipes and Tubes

Yantai Fangle Metallurgy Group Co., Ltd.- Condition:New

- Certification:CE, ISO9001

- Standard:DIN, ASTM, GB

- Customized:Customized

- Material:Alloy

- Application:Metal Processing Machinery Parts

Base Info

- Model NO.:as the drawing

- Application Range:Continuous Rolling Mill,Mpm,Fqm,Pqf

- Transport Package:Woodern Case

- Specification:max 20m, Diameter 100mm-500mm

- Trademark:FANGLE

- Origin:China

- Production Capacity:50000tons,Year

Description

Basic Info.

Model NO. as the drawing Application Range Continuous Rolling Mill,Mpm,Fqm,Pqf Transport Package Woodern Case Specification max 20m, Diameter 100mm-500mm Trademark FANGLE Origin China Production Capacity 50000tons/YearProduct Description

Chromium plating mandrel used for producing seamless steel pipes and tubesDescription

Chromium plating mandrel is a very important tool used in the continuous rolling mill to produce seamless steel pipes and tubes.The Mandrel bar is the important tool for mandrel rolling tube mills during seamless tubes and pipes production .

The mandrel bar is used to roll a pre-pierced steel billet to produce a tube blank (the preliminary seamless tube). The mandrel bar determines the shape of the inner tube surface.

During production ,the mandrel bar has to stand high temperatures, shock loading and high mechanical forces. This leads to heavy wear on the affected surfaces and significant material loss.With hardened and chromed surfaces ,basic wear resistance can be achieved, and by using ultraplate coating the mandrel life will be multiplied several times.

Products Parameters

| Materials | AISI H13, X35CrMo V51 ,4CrMoSi V1,28NiCrMoV10 etc. |

| Diameter | 80-600mm |

| Length | max to 20,000mm |

| Hardness | Meet the customers' requirements |

| Surface Processing | Chrome plating |

| Threading | Available, phosphating |

| Chrome plating | As per requirement,thickness 0.045-0.065mm |

| Process | EBT + LF (VD) + ESR |

| Property tests | Magnetic testing,Ultrasonic testing etc. |

| Lead time | about 45 days |

| Delivery condition | Finished machining |

| Application | MPM, PQF and FQM mills,Assel Mills,Accu-roll mill, Push Bench, Pilger mill,continuous tube mill etc |

| Market | India,Saudi Arab,Russia,Slovenia,Thailand,Vietnam etc. |

Production process:

1) forging

2) rough machining

3) magnetic test

4) heating treatment

5) ultrasonic test

6) finish machining

7) chromium plating

8) thread phosphating

9) package

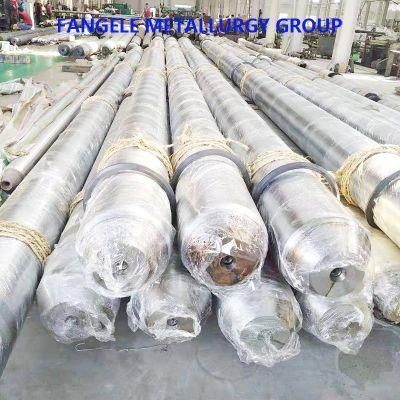

Mandrel products show

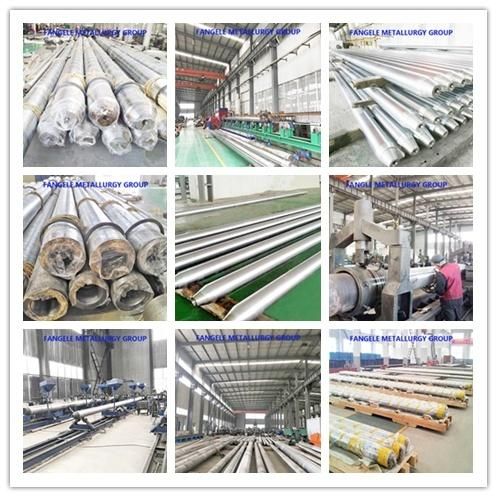

Mandrel workshop show

Mandrel workshop show

Customer Visit