Customized Casting Crusher Spare Parts with Aluminum

Qingdao Xinghe Machinery Co., Ltd.- Condition:New

- Certification:CE, RoHS, GS, ISO9001

- Standard:DIN, ASTM, GOST, GB, JIS, ANSI, BS

- Customized:Customized

- Material:Aluminum

- Application:Metal Recycling Machine, Metal forging Machinery, Metal Engraving Machinery, Metal Casting Machinery

Base Info

- Model NO.:OEM

- Name:Crusher Spare Parts

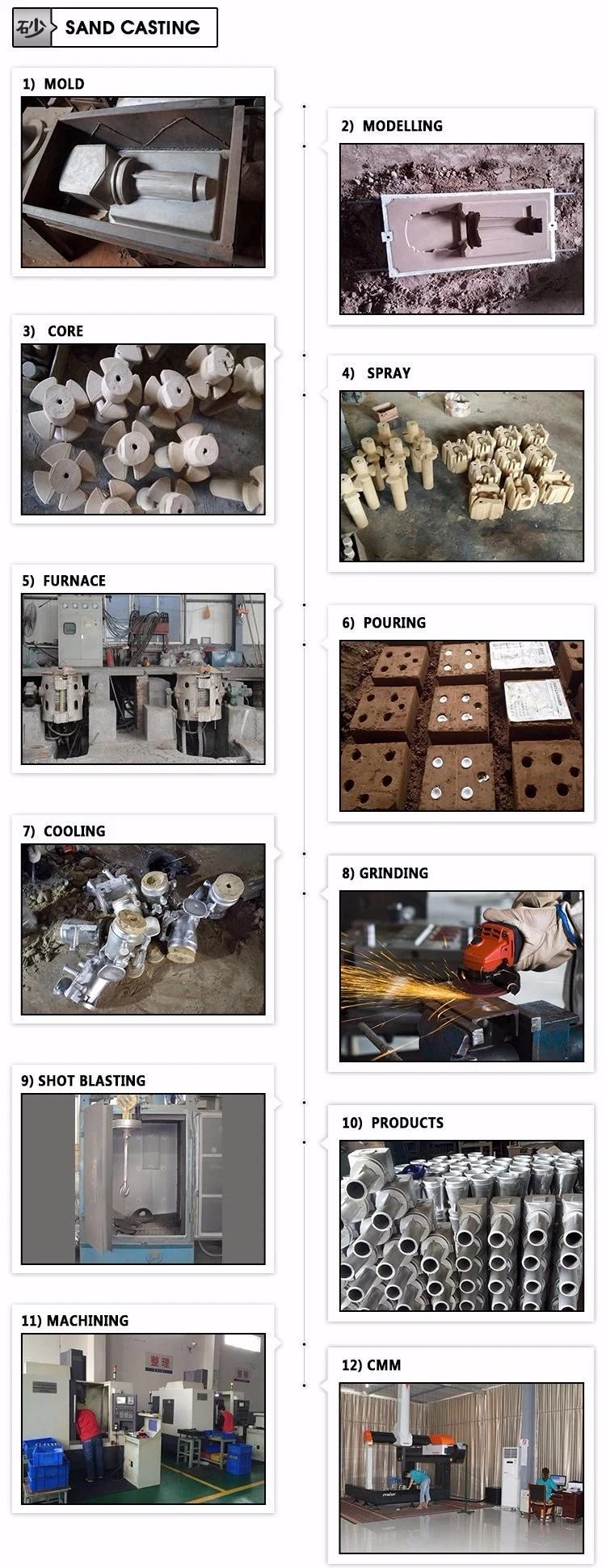

- Technology:Casting + Machining

- Machining:Grinding, Tapping

- Surface Treatment:Zinc Plate, Chrome Plate, Polishing, Paint

- Tolerance:+-0.5mm

- Delivery Time:15-30 Days After Payment

- Post-Processing:Heat Treatment

- OEM and ODM:100% with Dawings

- Testing:Magnetic Particle Inspector, CMM

- Transport Package:Wooden Crate or by Customer′s Reuirment

- Specification:OEM spear parts

- Trademark:XH

- Origin:Qingdao China

- HS Code:8708507100

- Production Capacity:1000 Tons Per Month

Description

2.Standard: ASTMDINBSJISGB.

3.Surface finish: shot blasting,sand blasting, polishing,painting, etc.

4.Weight: about 1-7000kg.

2.Machining facility: CNC machine, NC lathe, ordinary machine tools,linear cutting machine, polishing machine,welding machine.

Casting foundry:

In order to ensure the quality of the orders, our independent QC members to carry out strict inspection at each stage:

(1)Incoming material inspection

(2)Inspection of work-in-progress

(3)Finished product inspection

(4)Random warehouse inspections

All of our operations are strictly compliant with ISO 9001: 2008 guidelines

We own automated casting lines, CNC machining, CMM inspection, spectrometers and MT testing equipment, X-ray.

To benefit from our strong OEM/ODM capabilities and considerate services, contact us today. We will sincerely create and share success with all clients.