Rebar Connector Double Cylinder Steel Rebar Connection Upsetter Machine

Henan Yugong Machinery Co., Ltd.- Type:Upsetting Machine

- Forging Forming Method:Mold Forging

- Power Source:Electric

- Feature:High Efficiency

- Certification:ISO9001, CE

- Warranty:24 Months

Base Info

- Customized:Customized

- Advantage:Easy to Maintenance

- Condition:New

- Upsetting Range:16-40mm Machines for Cold Forging

- Upsetting Force:2036kn Cold Forging Machine

- Working Stroke:220mm Mesin Forging

- Motor Power:7.5kw Forging Machine

- Power:380V Machine Cold Forging

- Oil Pump Pressure:80MPa,50Hz Rebar Upsetting Machine

- Size:900×750×500mm

- Max. Flow:5.42L,Min Nut Bolt Making Machine Price

- Upsetting Length:3-5cm Nut Bolt Making Machine

- Increase Size:3-5mm Cold Forging Machine

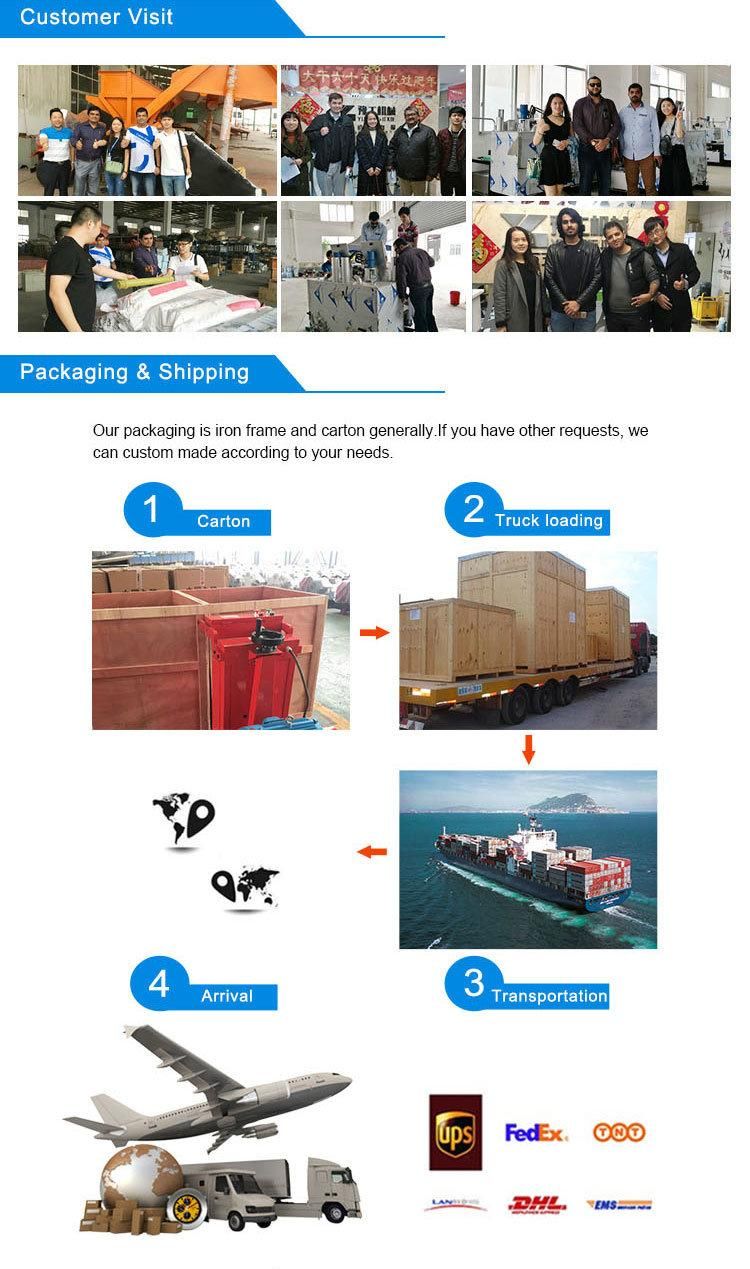

- Transport Package:Wooden Case Export Package

- Specification:1020*500*965

- Trademark:Yugong

- Origin:China, Henan

- HS Code:8479819000

- Production Capacity:10000

Description

Basic Info.

Customized Customized Advantage Easy to Maintenance Condition New Upsetting Range 16-40mm Machines for Cold Forging Upsetting Force 2036kn Cold Forging Machine Working Stroke 220mm Mesin Forging Motor Power 7.5kw Forging Machine Power 380V Machine Cold Forging Oil Pump Pressure 80MPa/50Hz Rebar Upsetting Machine Size 900×750×500mm Max. Flow 5.42L/Min Nut Bolt Making Machine Price Upsetting Length 3-5cm Nut Bolt Making Machine Increase Size 3-5mm Cold Forging Machine Transport Package Wooden Case Export Package Specification 1020*500*965 Trademark Yugong Origin China, Henan HS Code 8479819000 Production Capacity 10000Product Description

Steel Rebar Connection Upsetting MachineProduct Description

Steel upsetting machine using hydraulic cold heading of the principle of plastic deformation of steel ends, the diameter increases 4 ~ 6mm, and then processing thread. So that the actual cross-sectional area after processing thread larger than the original cross-sectional area of steel, greatly improving the tensile strength joints.

This upsetting of the threaded connector by the tensile test of all broken in the base metal for the higher requirements of engineering steel upsetting machine hydraulic technology, upsetting steel for straight thread connection technology, the use of sleeve connector . The device is suitable for the diameter of 16 ~ 40mmHRB335 ( grade steel), HRB400 ( grade steel) hot-rolled ribbed steel production upsetting straight thread steel joint.

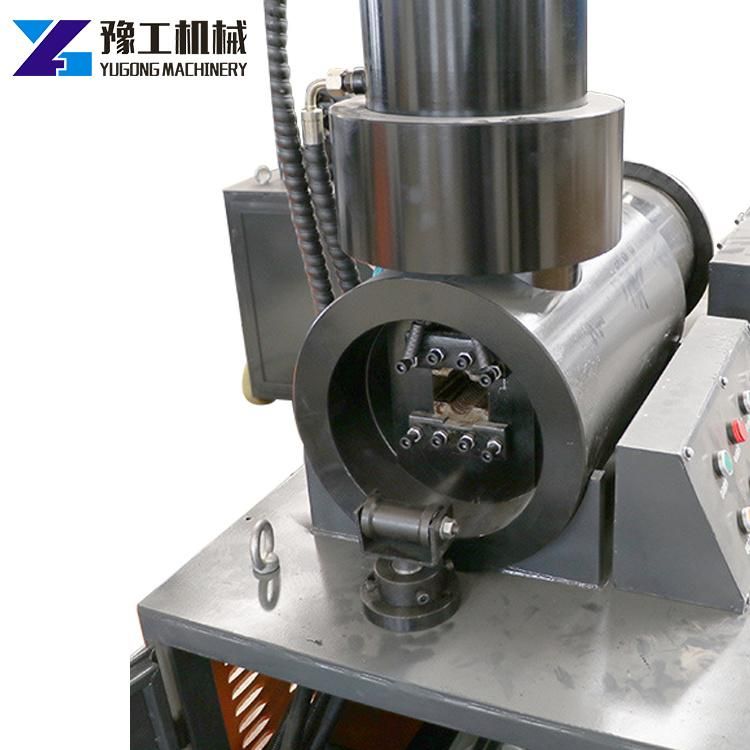

Machine Pictures

Technical Parameters

| Model | YDCJ-40 | SYDJ-40 |

| Upsetting Range | 16-40mm | 16-32mm |

| Upsetting Force | 2036KN | |

| Working Stroke | 220mm | 220mm |

| Motor Power | 7.5kw | 7.5kw |

| Power | 380V | 380V |

| Oil Pump Pressure | 80Mpa/50HZ | 30Mpa/50HZ |

| Size | 900×750×500mm | / |

| Max. Flow | 5.42L/min | / |

| Upsetting Length | 3-5cm | / |

| Increase Size | 3-5mm | / |

| Work Efficiency | 15-20s/pieces | 15s/pieces |

| Packing Size | 1020×500×965mm | 1250×850×1650mm |

| Weight | 900kg | 1000kg |

Product Features and Details

- High production efficiency,each hour can be upsetting 300-500 head.

- Processing a wide range of steel,which can be processed in line with HRB335 ( grade steel), HRB400 ( grade steel) standard Φ16-Φ40mm,various specifications of the steel.

- Equipment failure rate is small,non-fragile parts construction costs low.

- Environmental protection,security,it is not subject to environmental and climates changes.

- The end of the steel cross-sectional area expanded into the bottom diameter of the screw thread of base metal,fully play the tensile strength.

- Simple operation,hydraulic electrical control,do not need professional technicians training,ten minutes to boot operation.

Contact information