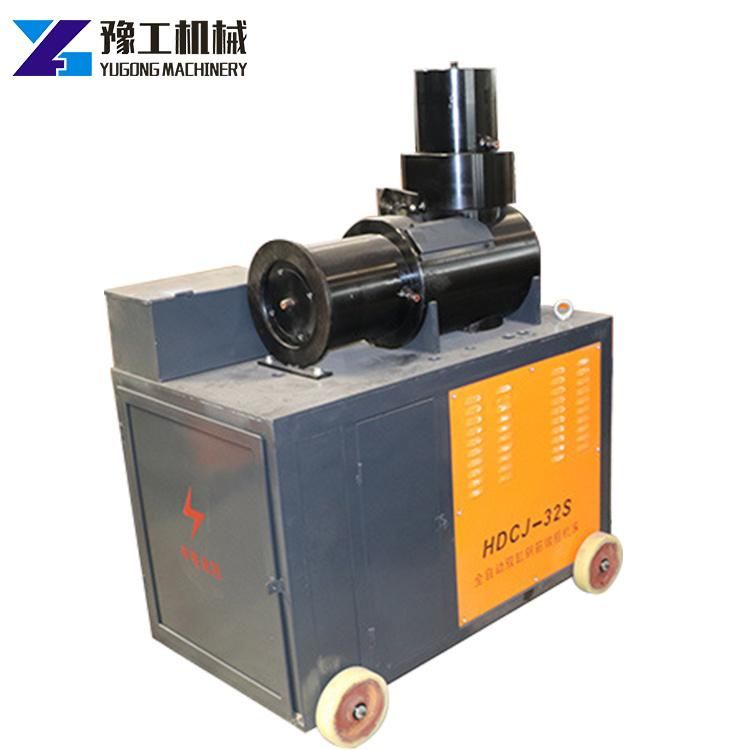

18mm Steel Bar Anchor Bolts Thread Rolling Reinforced Upsetting Machine

Henan Yugong Machinery Co., Ltd.- Type:Upsetting Machine

- Forging Forming Method:Mold Forging

- Power Source:Electric

- Feature:High Efficiency

- Certification:ISO9001, CE

- Warranty:24 Months

Base Info

- Customized:Customized

- Advantage:Easy to Maintenance

- Condition:New

- Upsetting Range:16-40mm Forging Machine

- Upsetting Force:2036kn Nut and Bolt Making Machine

- Working Stroke:220mm Nut Forging Machine

- Motor Power:7.5kw Cold Forging Machine Price

- Power:380V Nut Cold Forging Machine

- Oil Pump Pressure:80MPa,50Hz Bolt Making Machine Price

- Size:900×750×500mm

- Max. Flow:5.42L,Min Metal Forging Machinery

- Upsetting Length:3-5cm Upset Forging Machine

- Increase Size:3-5mm Nuts Making Machine

- Transport Package:Wooden Case Export Package

- Specification:1020*500*965

- Trademark:Yugong

- Origin:China, Henan

- HS Code:8479819000

- Production Capacity:10000

Description

Basic Info.

Customized Customized Advantage Easy to Maintenance Condition New Upsetting Range 16-40mm Forging Machine Upsetting Force 2036kn Nut and Bolt Making Machine Working Stroke 220mm Nut Forging Machine Motor Power 7.5kw Cold Forging Machine Price Power 380V Nut Cold Forging Machine Oil Pump Pressure 80MPa/50Hz Bolt Making Machine Price Size 900×750×500mm Max. Flow 5.42L/Min Metal Forging Machinery Upsetting Length 3-5cm Upset Forging Machine Increase Size 3-5mm Nuts Making Machine Transport Package Wooden Case Export Package Specification 1020*500*965 Trademark Yugong Origin China, Henan HS Code 8479819000 Production Capacity 10000Product Description

Steel upsetting machineProduct Description

Steel upsetting machine using hydraulic cold heading of the principle of plastic deformation of steel ends, the diameter increases 4 ~ 6mm, and then processing thread. So that the actual cross-sectional area after processing thread larger than the original cross-sectional area of steel, greatly improving the tensile strength joints.

This upsetting of the threaded connector by the tensile test of all broken in the base metal for the higher requirements of engineering steel upsetting machine hydraulic technology, upsetting steel for straight thread connection technology, the use of sleeve connector . The device is suitable for the diameter of 16 ~ 40mmHRB335 ( grade steel), HRB400 ( grade steel) hot-rolled ribbed steel production upsetting straight thread steel joint.

Technical Parameters

| Model | YDCJ-40 | SYDJ-40 |

| Upsetting Range | 16-40mm | 16-32mm |

| Upsetting Force | 2036KN | |

| Working Stroke | 220mm | 220mm |

| Motor Power | 7.5kw | 7.5kw |

| Power | 380V | 380V |

| Oil Pump Pressure | 80Mpa/50HZ | 30Mpa/50HZ |

| Size | 900×750×500mm | / |

| Max. Flow | 5.42L/min | / |

| Upsetting Length | 3-5cm | / |

| Increase Size | 3-5mm | / |

| Work Efficiency | 15-20s/pieces | 15s/pieces |

| Packing Size | 1020×500×965mm | 1250×850×1650mm |

| Weight | 900kg | 1000kg |

Product Features and Details

- High production efficiency,each hour can be upsetting 300-500 head.

- Processing a wide range of steel,which can be processed in line with HRB335 ( grade steel), HRB400 ( grade steel) standard Φ16-Φ40mm,various specifications of the steel.

- Equipment failure rate is small,non-fragile parts construction costs low.

- Environmental protection,security,it is not subject to environmental and climates changes.

- The end of the steel cross-sectional area expanded into the bottom diameter of the screw thread of base metal,fully play the tensile strength.

- Simple operation,hydraulic electrical control,do not need professional technicians training,ten minutes to boot operation.

Upsetting machine can be used with steel rolling machine, straight thread sleeve, suitable for demanding engineering

Packaging & Shipping

1. Packaging: 1)Wrapped by protective film;

2)Packed by standard import & export wooden cases or carton boxes.

2. Shipping: By logistics; by automobile; by train; by shipping; by air etc.

Payment Terms

We accept L/C, T/T, Western Union, Money Gram, Paypal, Alibaba Escrow etc.

Frequently Asked Questions

1. Q: Are you trading company or manufacturer?

A: We are original equipment manufacturer.

2. Q: How long is your delivery time?

A: It is according to the model and quantity.

Generally it is 3-5 days if the machines are in stock.

It will be 15-30 days if you want to customize the machines.

3. Q: Do you provide samples? Is it free or extra?

A: Yes, we could offer you the sample machine.

But it's not free. You need to pay for the sample and the cost of freight.

4. Q: What is your terms of payment?

A: We accept T/T, Western Union, Money Gram, Paypal, Alibaba Escrow etc.

Payment<=USD 5000, 100% in advance.

Payment>=USD 5000, 30% T/T in advance, balance before shipment.

About Us

Henan Yugong Machinery Co., Ltd. is a large machinery manufacturing enterprise which focuses on research and development, production and sales of mining, tunnel construction, road and bridge construction equipments and so on.

We believes that good quality can give us survival, thus we only provide you top products. All the products with high quality meet international standards and are highly estimated by all clients at home and abroad.

All the staff in our company are professionally trained, so we can recommend you the most appropriate equipment. Every machine will be strictly examined before delivery.

Any questions about the machine will be replied within 24 hours. Welcome you to be our new client!

Contact information