Complete Powder Coating Line for Coating Aluminium Profile

Colo International Corporation Group Ltd.- Type:Coating Production Line

- Coating:Powder Coating

- Substrate:Steel

- Certification:CE

- Condition:New

- System:for Automatic Powder Coating

Base Info

- Model NO.:COLO

- Payment:30% T,T in Advance, 70% T,T Before Delivery

- Working Voltage:380V or 220V

- Warranty:12 Months

- Size:Can Be Customized

- Transport Package:Wodden Case

- Specification:CE

- Trademark:COLO

- Origin:China

- HS Code:8424999990

- Production Capacity:20PCS,Year

Description

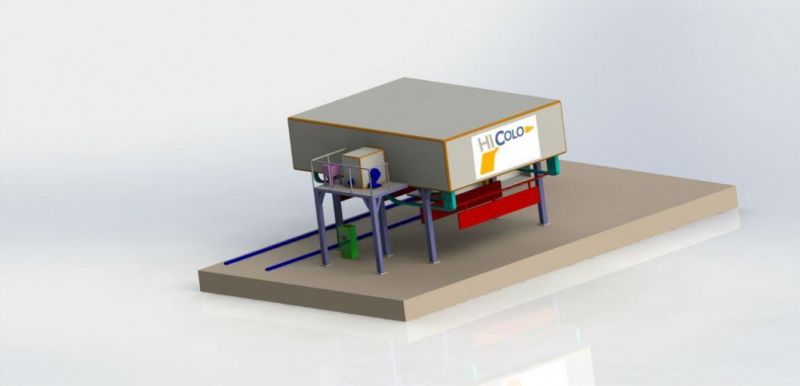

2.Compact aluminum profile powder coating line

Two synchronized conveyors,box oven,the conveyor is running in vertical plane instead of

horizontal plane,This design takes very small space,but need the height of 6m at least.

The capacity of theis design is limited,for example,for standard aluminum profile,about 3~4

tons of profile can be powder coated in 8 hours only.this type is a good choice for customers

with very limited space.

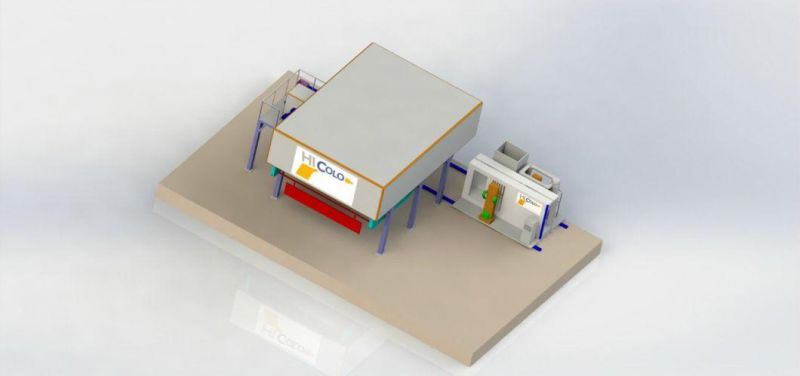

3.Traditional Horizontal aluminum Profile Powder coating line

The parts always move along with conveyor,even turn the corner,The output capacity will be

higher if the conveyor speed is faster,in this case,the curing oven lenght should be longer,so

the powder coated parts can be cured completely,this desigh is simple and reliable and the

maintenance is easy,but the production capacity is limited by oven lenght.

4.Vertical aluminum Profile Powder coating line

This type of powder coating line is especially designed for aluminum profile,The

norminal capacity of such line can reach to 40-60 tons per 8 working hours, considering

the weight of 4kg for a profile of 6 m long.

in vertical line,the aluminum profiles position are changed in loading section from horizontal into vertical,Then the profile go through the coating process and finally at unloading section,

the profiles position change into horizontal again.

The advantage of such line is its huge capacity,To install the vertical line,the height should be 14m,the huge equipment used in this line are manufactured exclusively for this type of line,The conveyor speed can be adjusted up to 3m/min.

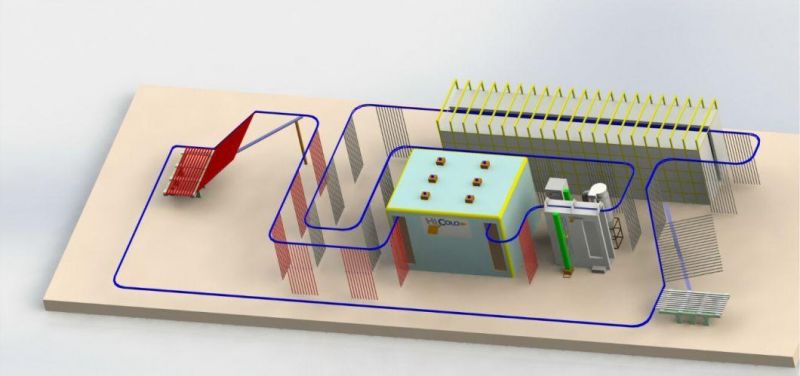

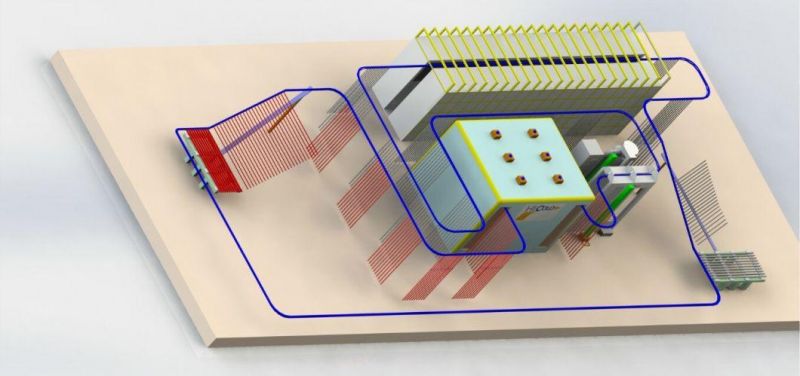

5. Power & Free conveyor line

power and free conveyor,box curing oven

Power and free conveyor is highly automatic and integratve,which can stop individual loads

without stopping the entire production line,The main conveyor is moving continuously,but

another loading conveyor just move step by step(position:inside the oven,loading & unloading area).

Manual powder coating system details:

Powder spray booth :

| 1.Powder recovery system | filter |

| 2.Spray Outdoor Dimensions | L4820mm × W1700mm × H2370mm workpiece exit and entry si |

| 3.workpiece exit and entry | W500mm × H1700mm |

| 4.Operating opening size | W600mm × H1400mm |

| 5.Spray from the spray plate assembly chamber material | (base: δ = 2.0mm, Spray chamber: δ = 1.5mm) |

| Color standard spray chamber | |

| Spray chamber square tube steel base material | |

| Lighting | 2 × 40W (4 sets) |

| Fan motor | 7.5kw |

Customer must provide: Air compressor: 3 m3 / min, providing a steady air pressure: 6.6Mpa ~ 0.8Mpa, no impurities, oil, water.

We can supply different 4 layout for aluminum profile powder coating line

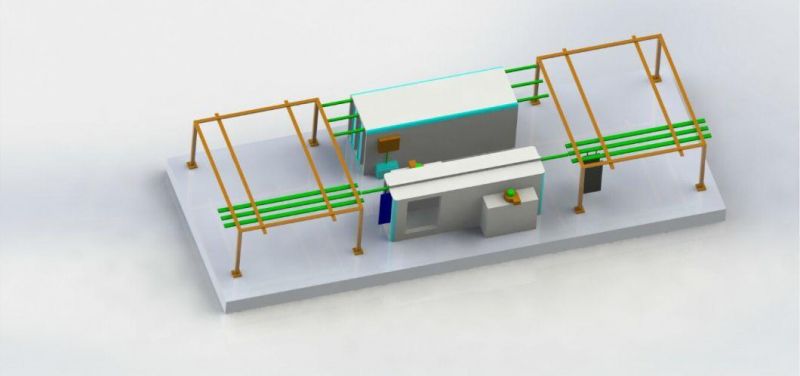

1.manual aluminum profile powder coating line

2.Compact aluminum profile powder coating line

3.Horizontal aluminum Profile Powder coating line

4.Vertical aluminum Profile Powder coating line

More intresting about the aluminum profile powder coating line please view more.

We are looking forward to get your enquiry

Contact : Diana

Telephone:86-13396500051