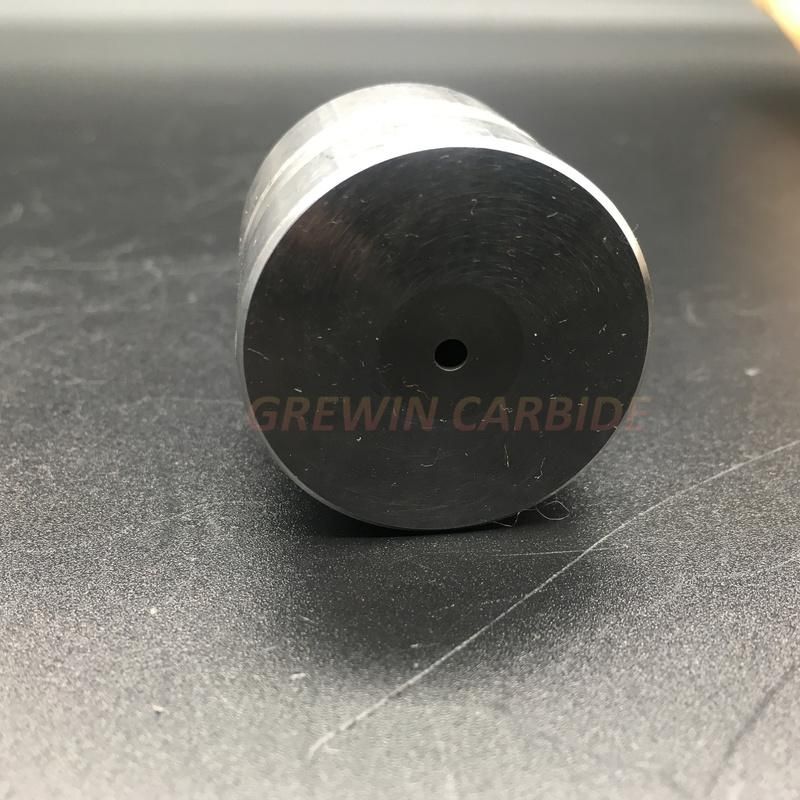

Gw Carbide - High Quality of Tungsten Carbide Brazed Steel Molds

Zhuzhou Grewin Tungsten Carbide Tools Co., Ltd.- Certification:ISO9001

- Application:Metal Cutting Machine, Metal Processing Machinery Parts, Household Appliances, Hardware, Commodity

- Processing Method:Punching and Shearing Mould

- Technics:Forming Die

- Process Combination:Progressive Die

- Manufacturing Technology:Computer Technology

Base Info

- Model NO.:All sizes

- Driving Motor Type:Permanent Magnet

- Mold Cavity Technology:EDM Milling

- Milling Speed:High Speed

- Parts Detection Method:Geometric Detection

- Material:Carbide

- Grades:Yg20c, Yg25c, Kg7, Va80, Va90, Wf40

- Tolerance:Rough Grind on O.D, Grind Top and Bottom Surface

- Delivery Time:3 ~ 15 Days

- Customized:Standard or Customised

- Surface:Grinding or Rough

- Work Piece:for Metal

- Shipment:by Express, Air, Sea, etc.

- Transport Package:Standard Export Carton

- Specification:33x23x19cm

- Trademark:G&W or OEM

- Origin:Zhuzhou, Hunan

- HS Code:8207209000

- Production Capacity:100 Tons Annually

Description

(g/cm3)

(N/mm2)

(HRA)

resistant or impact resistant application.

Production process

Mixture(WC+CO+alcohol)→wet grinding→ drying→grinding again→suppression(Oil press,Automatic hydraulic press)→QC for blank→rubber extrusion→Wc+Co→sintering(HIP )→tungsten carbide blank→Fine grinding→QC→packing.

Welcome for your inquiry!