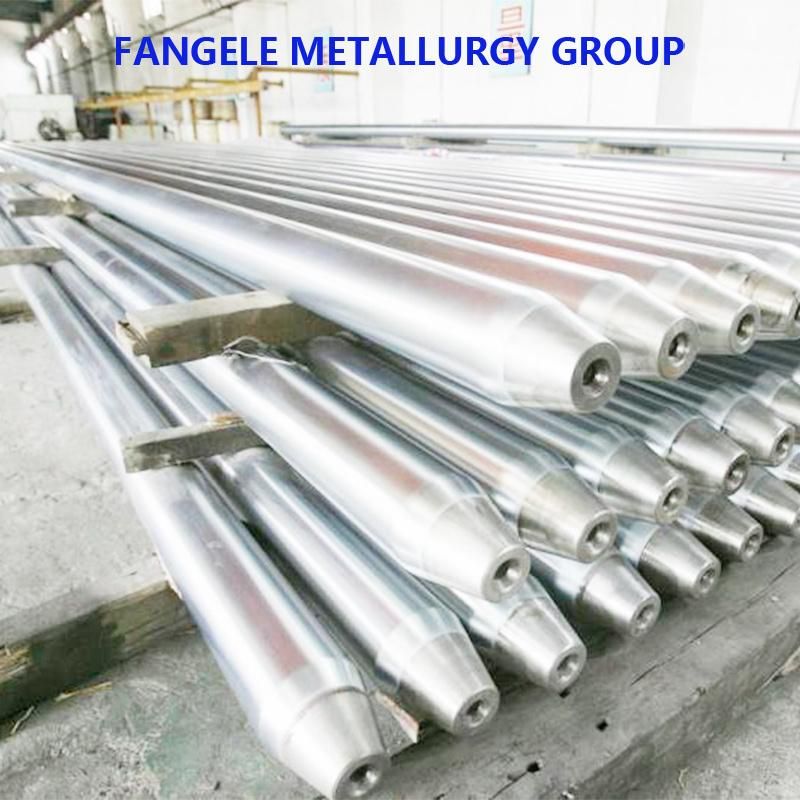

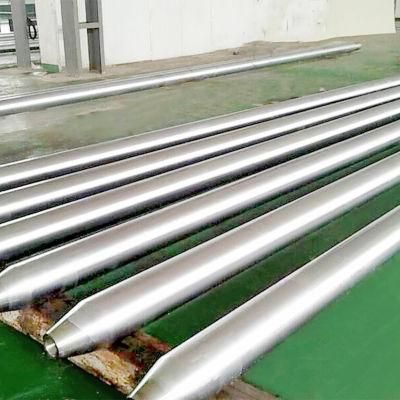

Mandrel Rolling Mills Mandrel Bar Used for Manufacturing Seamless Steel Tubes and Pipes

Yantai Fangle Metallurgy Group Co., Ltd.- Condition:New

- Certification:CE, ISO9001

- Standard:DIN, ASTM, GB

- Customized:Customized

- Material:Alloy

- Application:Metal Processing Machinery Parts

Base Info

- Model NO.:as the drawing

- Application Range:Continuous Rolling Mill,Mpm,Fqm,Pqf

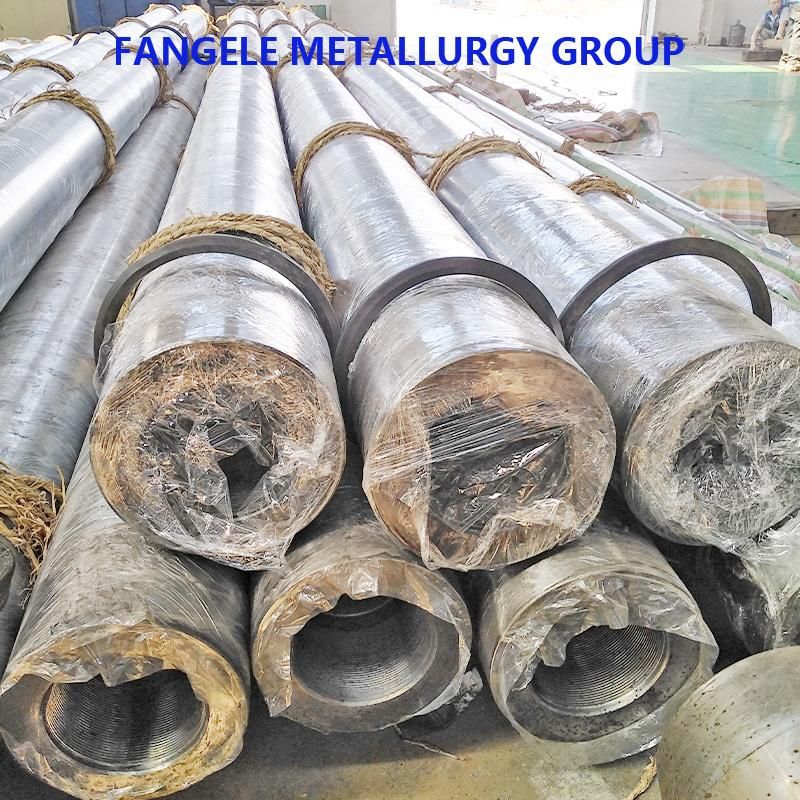

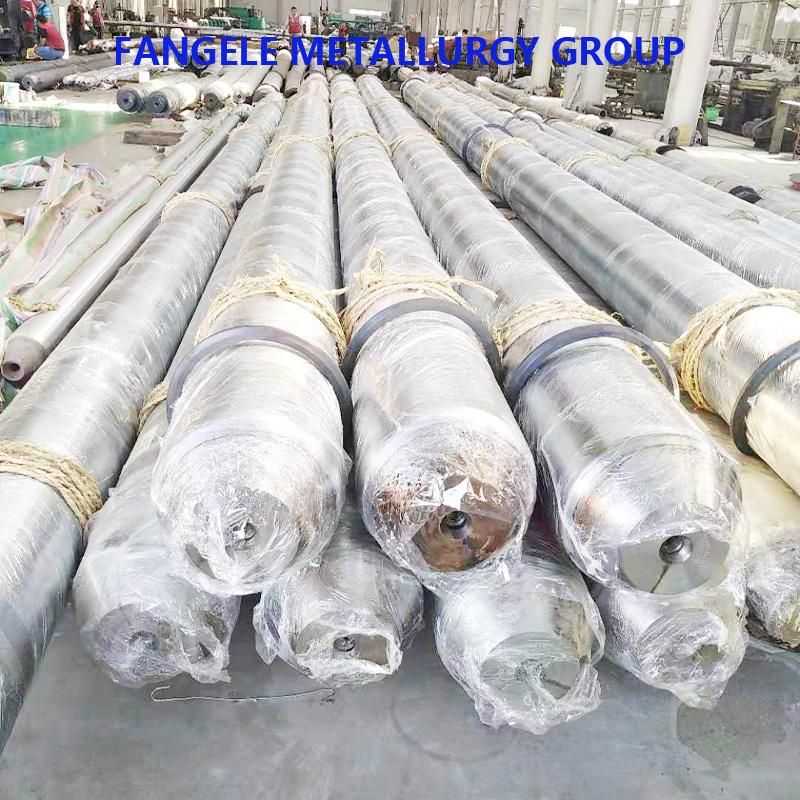

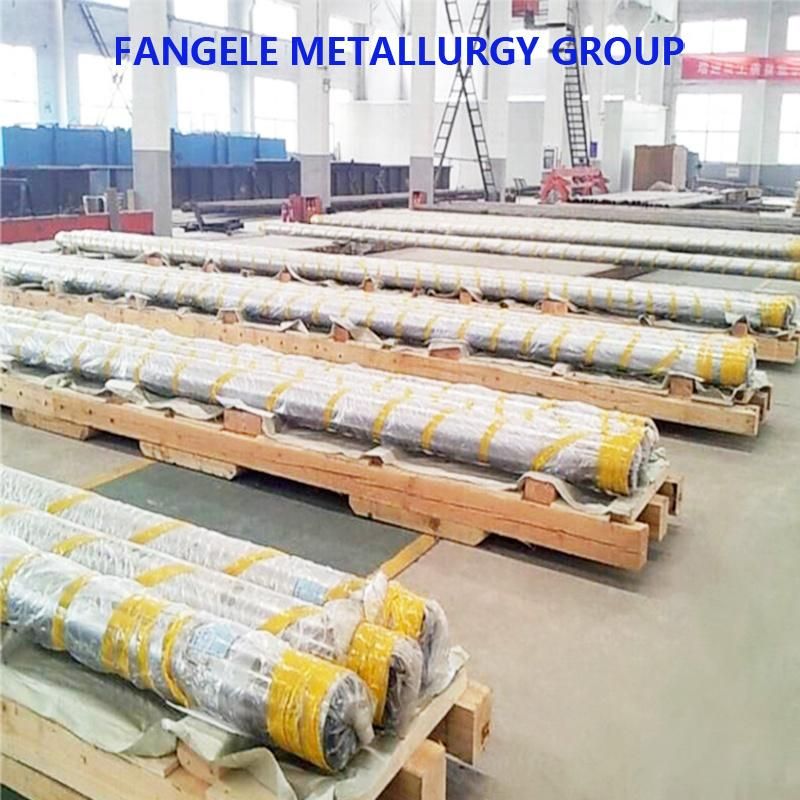

- Transport Package:Woodern Case

- Specification:max 20m, Diameter 100mm-500mm

- Trademark:FANGLE

- Origin:China

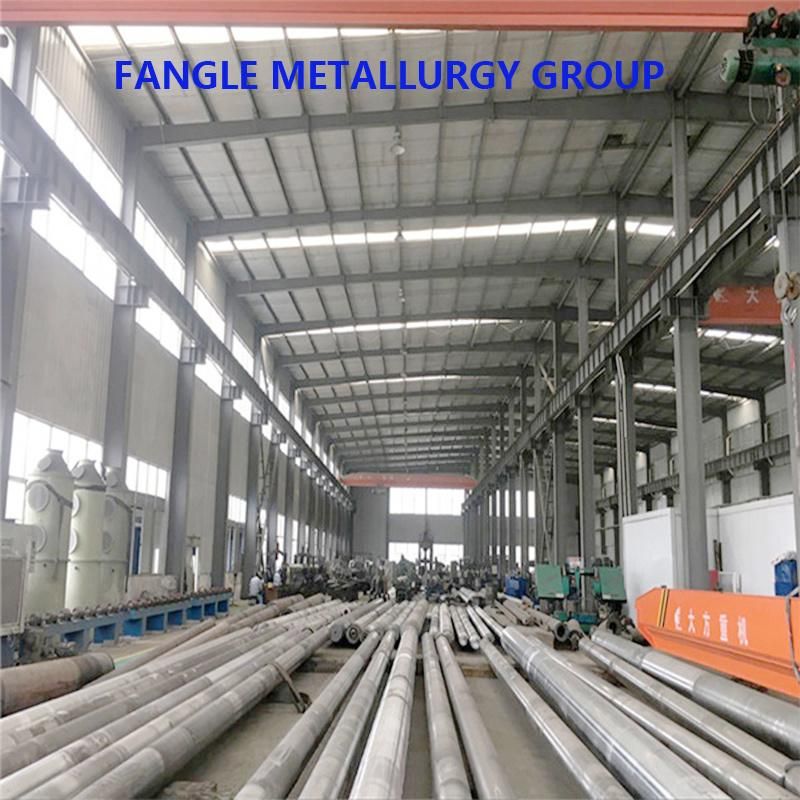

- Production Capacity:50000tons,Year

Description

Mechanical properties

Tensile strength: RM = 1050 MPa Minimum (105 kg/mm²)

RM = 1280 MPa Maximum (130 kg/mm²)

Yield strength: Ys ≥ 880 MPa

Elongation: Min .A=10%

Reduction of area: Min.Z=30%

Charpy V-Notch impact test: Min. Kv ≥ 20j, testing at room temperature.

Charpy tests will be in transverse orientations.

Application

- MPM-mill

- Continuous tube mill

- Push bench

- Assel mill