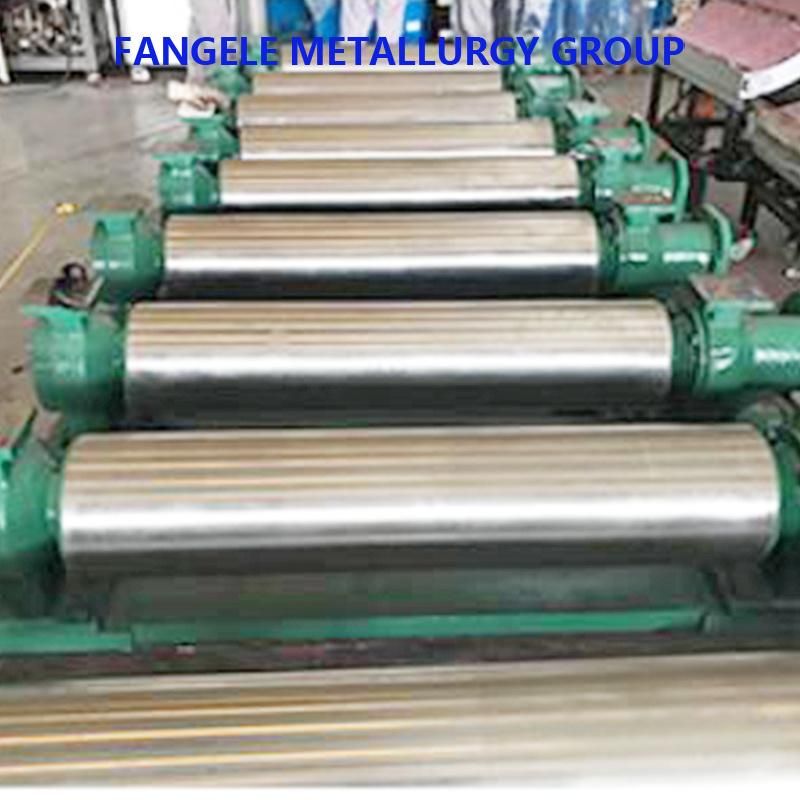

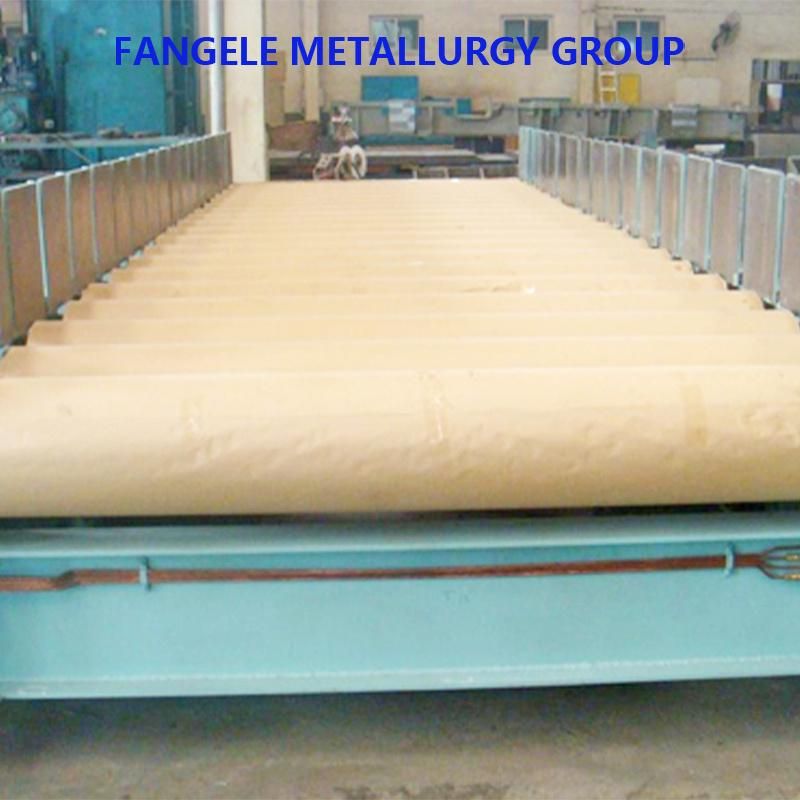

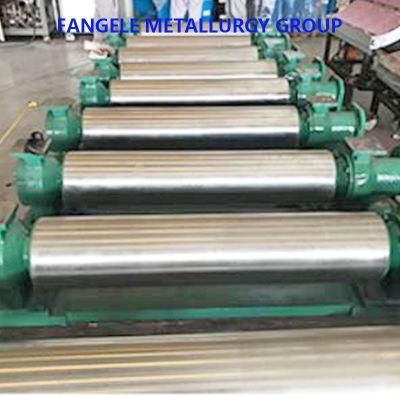

Laser Cladding Laminar Cooling Rollers for Producing Hot Rolling Strips

Yantai Fangle Metallurgy Group Co., Ltd.- Condition:New

- Certification:CE, ISO9001

- Standard:DIN, ASTM, GB

- Customized:Customized

- Material:Alloy

- Application:Metal Processing Machinery Parts

Base Info

- Model NO.:as the drawing

- Application Range:Cooling Table,Hot Strip Rolling Mill

- Transport Package:Polywood Case

- Specification:as the requirement

- Trademark:FANGLE

- Origin:China

- Production Capacity:60000tons,Year

Description

Basic Info.

Model NO. as the drawing Application Range Cooling Table,Hot Strip Rolling Mill Transport Package Polywood Case Specification as the requirement Trademark FANGLE Origin China Production Capacity 60000tons/YearProduct Description

Laminar cooling roller which locate between the finishing mill and the coiler is applied in cooling table of hot strip rolling mill. The temperature of the strip is tightly controlled by water cooling to ensure the normal operation of the coiling. The laminar cooling roll is mainly divided into the inner cooling roll and the outer cooling roll. When the hot rolling mill is in running, friction occur between hot rolling strip and roll ,and meanwhile the cooling roll surface is subjected to repeated erosion and cooling from the circulating water.Excellent cost performance: • Excellent hardened layer performance By utilizing the laser cladding technology characterized by rapid thermal and rapid cooling, the working procedure of preheating and annealing are eliminated. The base temperature is lowered to reduce the heat affect of the work-piece. The cladding layer and the base are highly metallurgical bonding. The cladding layer is finely organized without fine pores, and it has excellent wear resistance and corrosion resistance. • Stability & Reliability The roll body and the spindle head are made of higher strength material. Screw cutting, sand blasting and remelting are not required in the preparation process of the coating, which significantly improves the using strength of the cooling roll. Through the optimization and improvement of the bearing seal structure, the phenomena of bearing water ingress and jamming are effectively prevented. • The quality of strip steel is improved and the environmental pollution is reduced The service life of the roller itself is extended because of its excellent wear resistance and corrosion resistance, which better improve the surface quality of the strip steel products. The production process of high performance laminar cooling roll has low energy consumption and meets the requirements of green manufacturing without environmental pollution.