Corrugated Wall Roll Forming Machine Design

Hangzhou Zhongyuan Machinery Factory- Type:Roll Forming Machine

- Forging Forming Method:Cold Roll Forming

- Power Source:Electric

- Feature:Automation

- Certification:ISO9001, CE

- Warranty:12 Months

Base Info

- Model NO.:roll forming machine design

- Customized:Customized

- Advantage:Use Widely

- Condition:New

- Machine Size:About 11*1.6*1.4m

- Machine Weight:About 8t

- Main Motor:7.5kw

- Rollers Material:No.45 Forged Steel, Plated with Hard Chrom

- Cutter Material:Cr12 Mould Steel Being Quenched Treatment

- Cutting Style:Cut to Length

- Controlling System:Mitsubishi PLC & Converter

- Operation Language:English or as Per Client`S Required

- Guarantee Time:First Year Free, Lifetime Services

- Quality System:ISO

- Transport Package:1*40gp Container for One Machine

- Specification:CE SGS BV

- Trademark:zhongyuan

- Origin:China

- HS Code:84552210

- Production Capacity:15sets,Month

Description

ItemSpecification

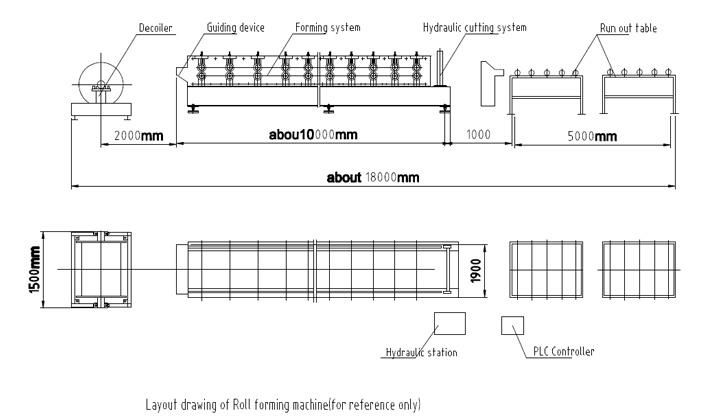

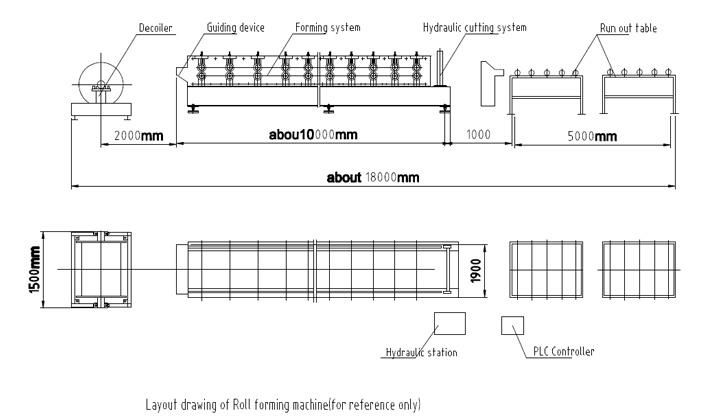

Raw Material Type Pre-painted steel coil & galvanized coils Thickness(mm) 0.3-0.7 Yield strength(mpa) 235-550 Shaft for rollers Solid shaft with 72mm,processed with cylindrical grinder Forming speed(m/min) About 20 Output speed(m/min) About 12 for 6m length sheet Speed adjusting mode Mitsubishi frequency transformer Roller drive Decelerating motor + Chain drive Cutting mode Hydraulic cutting Length measurement Nemicon Encoder Control mode Mitsubishi PLC Operating mode Button + Mitsubishi Touch screen Main motor power(kw) 7.5KW Total power(kw) 9.9 KW Process flow Decoiler -- Feeding & Guiding -- Roll forming---Hydraulic Cutting - product to run out table

Components of machineDecoiler (manual decoiler and hydraulic decoiler

for option)1set Feeding & guiding device 1set Main roll forming machine 1set Hydraulic cutting system 1set Controlling system 1set Run out table (auto. Stacker for option) 1set

We customize your machines! To customize machine, we would love to know:

1. Profile drawing

2. Raw material: the width(1250mm?), thickness(0.3-0.7mm?), and yield strength of steel coil.

3. Voltage: designed per your requirement

4. Configuration requirement: Hydraulic or manual decoiler/ stacker

Have no idea about them?

We will be glad to recommend the lacol popular profile for you----Just let us know your country!

Quality by Zhongyaun

Zhongyuan is certified according to the standards ISO 9001: 2008 and EN982: 2008, EN ISO12100-1: 2003, EN ISO 14121-1: 2007.

About us

We are professional in making roll forming machines since 2003. Company occupies 6650, in which 5650 for workshops.

1. Capacity: 12-15 sets/month

2. Delivery: in only 5-8 weeks for urgent order

3. Have our own tool center. 12 sets CNC machines.

4. Zhongyuan is a "All-in-house source"

--from raw material to the final high-precision forming machine. We have our precise tooling center.

5. You can rely on our team!

We have engineers with experience more than 15 years in metal forming industry.

Please feel free to contact us for more information!

Raw Material

Components of machineDecoiler (manual decoiler and hydraulic decoiler

for option)

We customize your machines! To customize machine, we would love to know:

1. Profile drawing

2. Raw material: the width(1250mm?), thickness(0.3-0.7mm?), and yield strength of steel coil.

3. Voltage: designed per your requirement

4. Configuration requirement: Hydraulic or manual decoiler/ stacker

Have no idea about them?

We will be glad to recommend the lacol popular profile for you----Just let us know your country!

Quality by Zhongyaun

Zhongyuan is certified according to the standards ISO 9001: 2008 and EN982: 2008, EN ISO12100-1: 2003, EN ISO 14121-1: 2007.

About us

We are professional in making roll forming machines since 2003. Company occupies 6650, in which 5650 for workshops.

1. Capacity: 12-15 sets/month

2. Delivery: in only 5-8 weeks for urgent order

3. Have our own tool center. 12 sets CNC machines.

4. Zhongyuan is a "All-in-house source"

--from raw material to the final high-precision forming machine. We have our precise tooling center.

5. You can rely on our team!

We have engineers with experience more than 15 years in metal forming industry.

Please feel free to contact us for more information!