2standing Seam Roofing Roll Forming Machine with Hydraulic Panel Sheet

Xiamen Xinhonghua Machinery Co., Ltd.- Type:Rolling Machine

- Forging Forming Method:Mold Forging

- Power Source:Hydraulic Pressure

- Feature:Automation

- Certification:SGS

- Warranty:12 Months

Base Info

- Model NO.:YX65-425

- Customized:Customized

- Advantage:Work Flexible

- Condition:New

- Motor Power:7.5kw*2

- Hydraulic Power:2.2kw

- Voltage:380V,50Hz,3pH

- Forming Steps:13

- Working Speed:10-14m,Min

- Effective Width:425mm

- Material Width:600mm

- Thickness for Aluminum:0.4-1.0mm

- Thickness for Steel:0.5-0.8mm

- Delivery Time:Delivery Immediately After The Machine Is Assemble

- Transport Package:Standard Package for Export

- Specification:SGS

- Trademark:XHH

- Origin:Xiamen of China

- HS Code:8455229090

- Production Capacity:10-15 Sets,Month

Description

Basic Info.

Model NO. YX65-425 Customized Customized Advantage Work Flexible Condition New Motor Power 7.5kw*2 Hydraulic Power 2.2kw Voltage 380V/50Hz/3pH Forming Steps 13 Working Speed 10-14m/Min Effective Width 425mm Material Width 600mm Thickness for Aluminum 0.4-1.0mm Thickness for Steel 0.5-0.8mm Delivery Time Delivery Immediately After The Machine Is Assemble Transport Package Standard Package for Export Specification SGS Trademark XHH Origin Xiamen of China HS Code 8455229090 Production Capacity 10-15 Sets/MonthProduct Description

The informaitons of YX65-425 Standing seam roof panel roll forming machine, roll forming machine, cold roll forming machine, metal stud roll forming machine are as following:

Main Accessories:

(1) Main standing seam roof panel roll forming machine ;

(2) 5 Tons Manual Uncoiler for Coil Width 1220mm;

(3) Hydraulic System;

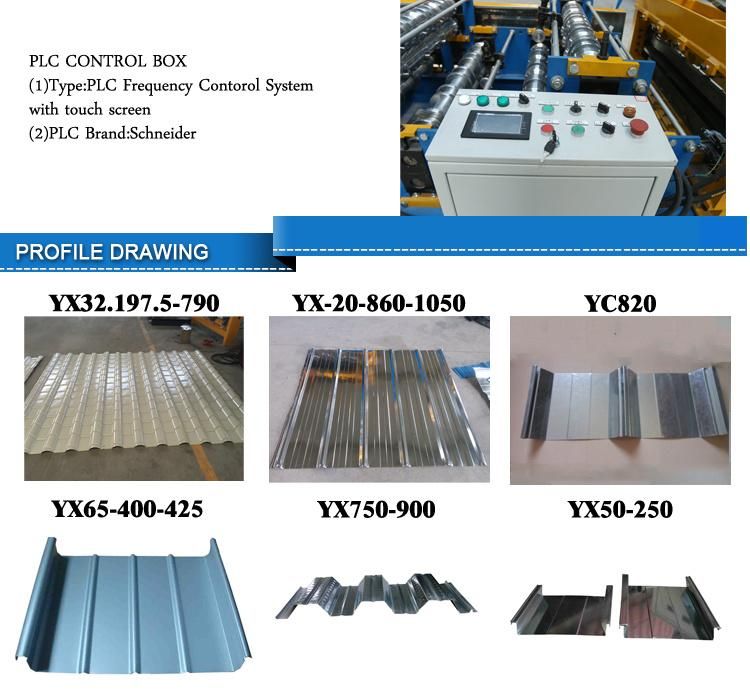

(4) PLC Computer Controlling System With Touch Screen

( Brand: Delta from Taiwan );

(5) Hydraulic Forming Cutter( 2 sets, one set for YX65-400, another set for YX65-500 );

(6) Device for making tapered standing seam roofing;

(7) Protective Cover;

(8) Auto Seamer(2 sets);

(9) Hand Seamer( 2 sets);

(10) Run out tables(3 PCS);

(11) Tools;

(12) Operation Manual.

Main Technic Data

Size | 5800*1800*1500mm |

Weight | 6500KGS |

Hydraulic Motor Power | 2.2KW |

Motor Power | 7.5KW*2 |

Forming Steps | 13steps |

Processing Speed | 10-14m/min |

Voltage | 380V/50HZ/3PH |

Height of Roofing | 65mm |

Effective Width | 425mm |

Feeding Material Width | 600mm |

Thickness for Aluminum Sheet | 0.4-1.0mm |

Material of principal axis | high grade 45# forged steel |

Material of roller | high grade 45# forged steel,Plated Hard chrome on the surface of rollers, and polished |

Material of blade | Cr12 mould steel with quenched treatment 60-62°C |

Material for frame of machine | Fine welded structural steel |

Material for producing roofing | normal Aluminum sheets |

Feature:

A.one standing seam roofing machine can make the straight shape and tapered shape roofing panels;

B.one standing roof panel machine can make several types roofing panel, can save more room, labor, time and cost.