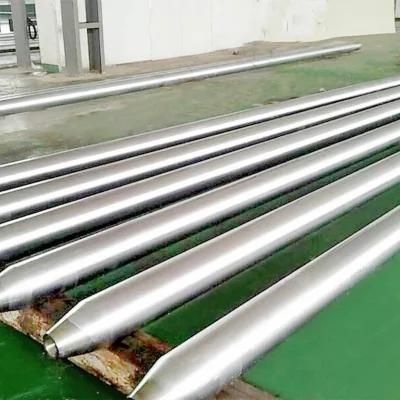

Mandrel Bar with Chrome Plating Used for Mandrel Mill Process

Yantai Fangle Metallurgy Group Co., Ltd.- Condition:New

- Certification:CE, ISO9001

- Standard:DIN, ASTM, GB

- Customized:Customized

- Material:Alloy

- Application:Metal Processing Machinery Parts

Base Info

- Model NO.:as the drawing

- Application Range:Continuous Rolling Mill,Mpm,Fqm,Pqf

- Transport Package:Woodern Case

- Specification:max 20m, Diameter 100mm-500mm

- Trademark:FANGLE

- Origin:China

- Production Capacity:50000tons,Year

Description

Basic Info.

Model NO. as the drawing Application Range Continuous Rolling Mill,Mpm,Fqm,Pqf Transport Package Woodern Case Specification max 20m, Diameter 100mm-500mm Trademark FANGLE Origin China Production Capacity 50000tons/YearProduct Description

Hard chrome plated mandrel bar used for mandrel mill processDescription

Mandrel bar with chrome plating plays a very important role in the mandrel mill process. The Mandrel is the important tool for MPM or FQM during seamless tube production .When rolling seamless tubes, a pre-pierced steel billet is rolled over a mandrel bar by grooved rolls in a stretch reducing rolling process to produce a tube or a tube blank. The mandrel bar determines the shape of the inner tube surface.During production ,it needs 6-7 pieces mandrel to stand by in turns .its surface temperature will reach 700ºC during production and then cooled to 80-120ºC after production ,it requires good quality and long lifetime. Mandrel bars are manufactured with lengths of up to roughly 20 m and production diameters of currently up to a maximum of 500 mm.

Production process:

1) forging

2) rough machining

3) magnetic test

4) heating treatment

5) ultrasonic test

6) finish machining

7) chromium plating

8) thread phosphating

9) package

Products Parameters

| Materials | AISI H13, X35CrMo V51 ,4CrMoSi V1,28NiCrMoV10 etc. |

| Diameter | 80-600mm |

| Length | max to 20,000mm |

| Hardness | Meet the customers' requirements |

| Surface Processing | Chrome plating |

| Threading | Available, phosphating |

| Chrome plating | As per requirement,thickness 0.045-0.065mm |

| Process | EBT + LF (VD) + ESR |

| Property tests | Magnetic testing,Ultrasonic testing etc. |

| Lead time | about 45 days |

| Delivery condition | Finished machining |

| Application | MPM, PQF and FQM mills,Assel Mills,Accu-roll mill, Push Bench, Pilger mill,continuous tube mill etc |

| Market | India,Saudi Arab,Russia,Slovenia,Thailand,Vietnam etc. |

Mandrel products show

Mandrel workshop show

Customer Visit