China Factory Aluminum Aluminium Alloy Custom Made CNC Machining Milling Turning Aeronautic and Aerospace Parts

Wuhan ZHD Precision Technology Co., Ltd.- After-sales Service:Deliver New Parts If Due to Our Responsibility

- Warranty:Deliver New Parts If Due to Our Responsibility

- Condition:New

- Certification:RoHS, ISO9001

- Standard:DIN, ASTM, GB, JIS, ANSI, BS

- Customized:Customized

Base Info

- Model NO.:According to the Customer

- Material:Alloy

- Application:Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal forging Machinery

- Surface Process:Multi-Option

- OEM:Available

- Designing:Available

- Transport Package:Carton

- Specification:According to the drawings of customers

- Trademark:Customer′s Own Brand

- Origin:Wuhan, China

- HS Code:8401200000

- Production Capacity:5000PCS,Year

Description

Basic Info.

Model NO. According to the Customer Material Alloy Application Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal forging Machinery Surface Process Multi-Option OEM Available Designing Available Transport Package Carton Specification According to the drawings of customers Trademark Customer′s Own Brand Origin Wuhan, China HS Code 8401200000 Production Capacity 5000PCS/YearProduct Description

Note: The products that are exhibited in this site are just sample parts we once machined according to customers' drawings, and the prices shown are NOT the real prices. We do machining service for customers and quote the prices according to specific parts and specifications.Our Procedure for Customizing Parts for You Is as Follows:

- Customer provides 2D or 3D drawings;

- We quote the prices according to your drawings(we can also design the parts according to your specific requirements);

- Orders are confirmed by both parties;

- We start to put your parts into machining;

- We package and deliver the parts the customer;

Description of This Part in the Picture

Material:

2A12 -T4

Workpiece Use

This workpiece is an aeronautic and aerospace component with extremely high precision requirements.

Processing Technology

This is an aviation part

1: Rough turning first, the contour stock shall be removed.

2: Aging treatment to remove the stress generated in the material from machining.

3: Finish machining to ensure that its cylindricity is within 0.007mm and the diameter tolerance value is + 0.013mm.

4: Finish milling for the machining of the weight-reducing part.

5: The gear part shall be machined by slow wire cutting to ensure that the tooth surface accuracy is within 0.005mm.

Surface Treatment

Spray very fine sand + natural color oxidation

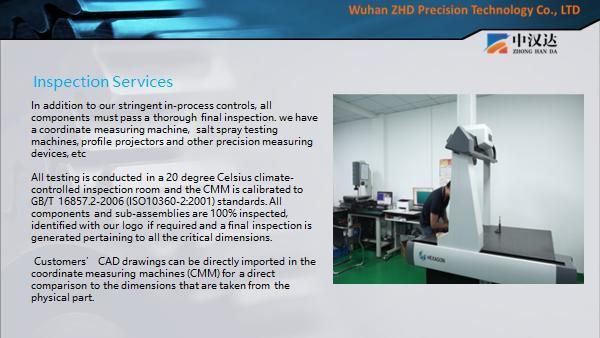

Inspection

CMM inspection is required and a report of qualification is issued.

General Information of Our Products and Services

1. Scope of Typical Parts

Parts of automation equipment, lasers, optical fiber electronics, optical lens, infrared thermal imaging devices, automobile and so on.

2. Scope of Workpiece Materials

Metal materials: stainless steel, aluminum, aluminum alloy, magnesium alloy, brass, mild steel, Cr12, SKD11 and so on.

Non-metal materials: POM, ABS, acrylic, nylon, PC, PMMA, Bakelite, PEEK, Teflon and so on.

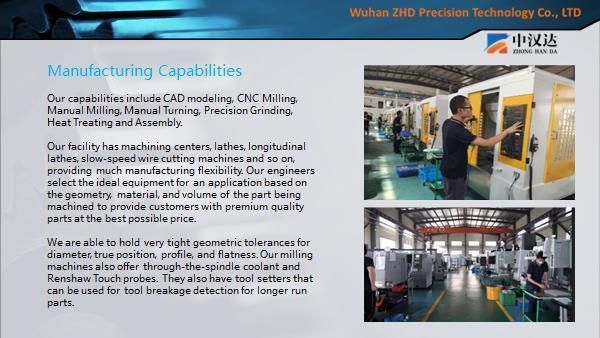

3. Machining Methods

Milling, turning, medium-speed wire cutting, slow-speed wire cutting, grinding, turning and milling forming)

4. Tolerance Ranges

Metal Machining: 0.01mm, depending on the product.

Non-metal Machining: 0.02mm, depending on the product.

5. Surface Roughness Range

Ra < 0.8, depending on the product and material.

6. Workpiece Size Range

10-500mm

7. Surface Treatment Options

Aluminum alloy: black oxidation, natural color oxidation, color oxidation, hard oxidation, micro arc oxidation, conductive oxidation.

Stainless steel: passivation, black zinc plating, blackening, PVD.

Steel: blackening, bluing, chromium plating, nickel plating, black zinc plating, color zinc plating, white zinc plating, paint copper: gold plating, silver plating, blackening, passivation, etc.

8. Lead Time for Samples

It takes about 15 days for production, depending on the product.

9. Lead Time for Formal Orders

It's determined according to order quantity and other requirements.

10. MOQ

5 pieces.

11. Payment Terms

Normally, T/T 30% is to be prepaid and balance paid before shipment for the first order, or decided by negotiation.

12. Transportation

0.1-150 KG: DHL air freight is prioritized.

Over 150 KG: Air or ocean freight with customs declaration.

13. Packaging

Foam sealing, independent carton, self-sealing bag, oil paper, vacuum packaging, etc.

14. Options of Transportation Companies

Air Freight: Fedex, DHL, UPS, TGL, etc .or according to customer's requirement.

Ocean Freight: DIMERCO, Agility, or according to customer's requirement.

15. Port of Delivery

Shanghai, or according to customer's requirement.