Complete Welding Wire Copper Coating Production Line

Wuxi Pingsheng Science & Technology Co., Ltd.- Warranty:1 Year

- Type:LZ Straight-Line Metal Drawing Machine

- Usage:Wire, Prestressed Steel Wire

- Metal Material:Steel

- Outlet Diameter:0.8-2.0mm

- Max.Inlet Wire Dia.:6.5mm

Base Info

- Block Dia.:600mm

- Max. Number of Block:12

- Certification:ISO

- Condition:New

- Transport Package:Plastic Film; Wooden Box

- Trademark:N,M

- Origin:Jiangsu

- HS Code:8463102000

- Production Capacity:100sets,Year

Description

Basic Info.

Block Dia. 600mm Max. Number of Block 12 Certification ISO Condition New Transport Package Plastic Film; Wooden Box Trademark N/M Origin Jiangsu HS Code 8463102000 Production Capacity 100sets/YearProduct Description

COMPLETE WELDING WIRE COPPER COATING PRODUCTION LINE---------------------------1.Welding wire specification

| Sr. | Item | WELDING WIRE |

| 1 | Model | Copper coating welding wire |

| 2 | Material | SV08G2C, H08A |

| 3 | Output diameter (mm) | 0.8, 1.0, 1.2, 2.0 |

| 4 | Inlet diameter (mm) | 5.0-5.5 |

| 5 | Finishes station | Copper coating and polishing wires |

| 6 | Capacity | About 6000t |

| 7 | Work system | 24h/day, 7500h/year |

-------------------------2. Main process:

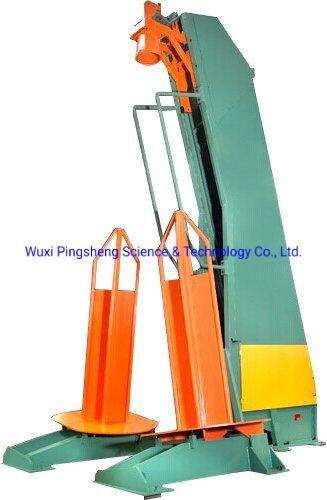

Straight line drawing: Wire rod → Lifting hydraulic pay-off → Mechanical wire descaling 8BK→ Double head abrasive belt grinding machine 2SD-8→Straight line wire drawing machine LW1+LZ7/560 → Spiral brush device for dust removal→ hot water washing and drying→ Spooler take up GS822(630)

Wet type drawing+ Copper coating+Polishing: Spool pay-off GF822(630)→ wet type wire drawing machine LT11/380 → Straight electrolytic copper coating line→ Water washing tank →Electromagnetic drying→Polishing drawing machine→ Spooler take up GS822(630)

Layer Rewinding part

--------------------------

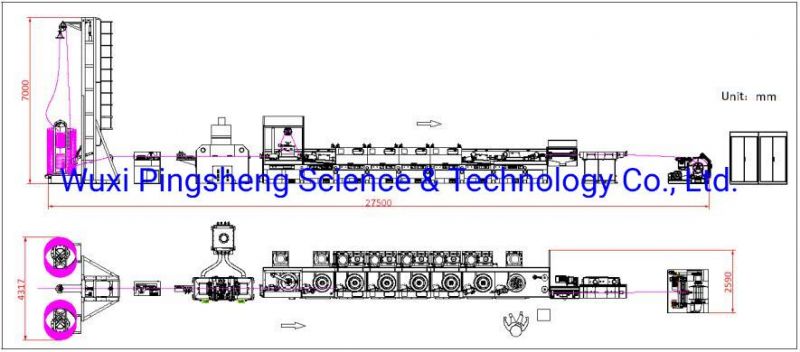

3. Layout:

------------------------------

4. Main pictures:

--------------------------------------------------------------------

5. Contacy ways