Machined/Turned/Milled/Machine/Turning/Turned/Milling/Forging/Steel/Metal/Machinery Part

Jingjiang Jinlun Machine Manufacturing Co., Ltd.- Condition:New

- Certification:CE, ISO9001

- Standard:DIN, ASTM, GOST, GB, JIS, ANSI, BS

- Customized:Customized

- Material:Metal

- Application:Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery

Base Info

- Model NO.:250mm

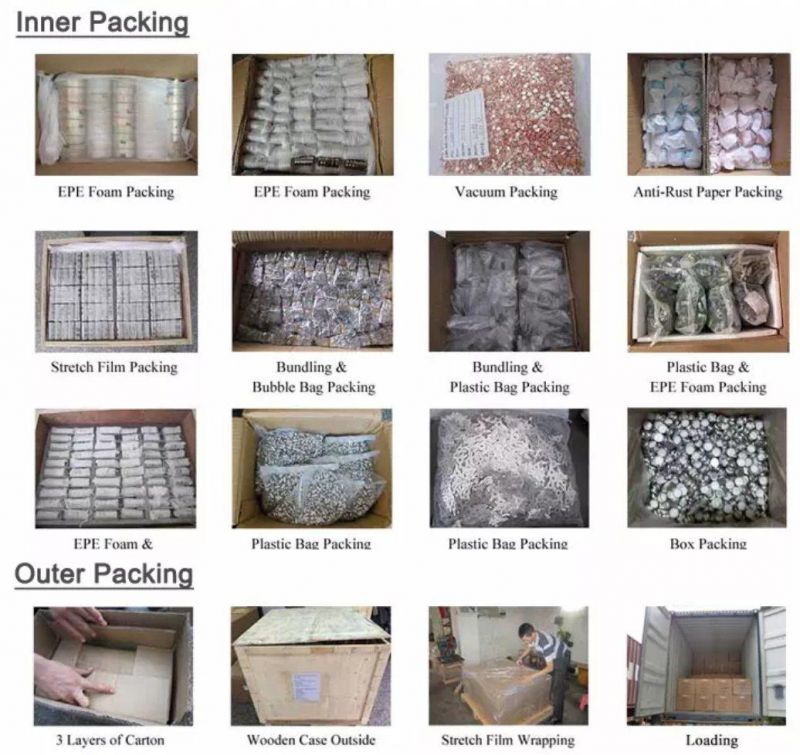

- Transport Package:Wooden Boxes

- Specification:25kg

- Production Capacity:50000PCS Per Year

Description

Basic Info.

Model NO. 250mm Transport Package Wooden Boxes Specification 25kg Production Capacity 50000PCS Per YearProduct Description

CNC turned and machined parts, bearing roller bodies for support wheels.

CNC turned and machined parts, bearing roller bodies for support wheels.

Types of our lathes: CNC Horizontal lathes and vertical lathes.

Machining/Turning diameter of our lathes: From 10mm to 5,000mm.

Machining/Turning length of our lathes: Up to 10,000mm.

Raw materias of CNC machined part: Forgings, castings, round bars, pipes, plates, etc.

Material quality of lathe part: Carbon steels, alloy steels, tool steels, stainless steels, aluminium, copper, bronze, etc.

Quality checking equipment of lathe part: Calliper, microcalliper, gauge, 3D checking machine.

We had manual lathes for pre-turning, CNC lathes for final turning. CNC machining centers for milling, drilling, threading, etc.

JINLUN is located in Jingjiang which is a flourishing port city near to Shanghai. The company covers an area of around 18,000 square meters.

We are the expert of iron, steel, stainless steel, aluminium and copper products processing company since the year 1999. We had the competences of forging, foundry, normal machining, CNC machining, cutting, turning, milling, drilling, threading, grinding, assembling, etc. We had the wide range of materials processed, including the iron, steel, stainless steel, alloy, aluminium, copper, bronze, forging, casting and other materials according to the customer's required. We are certificated by the ISO9001-2015 Quality-Austria system.

We export thousands ton mechanical products to Europe per year, except these, we also export the assembled machines, bearings, motorized spindles, electric motors, valves and pumps.

Customized made is our core business.Thanks for the long experiences in the field of forging, casting and machining, we can always find the right and economical solutions for our customers.

You are always welcomed at JINLUN!