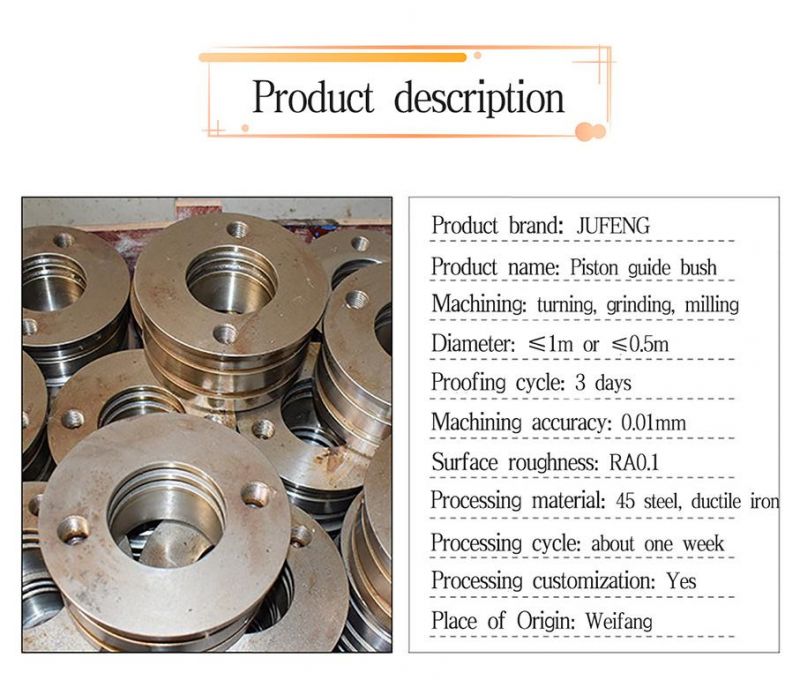

Customized CNC Machining Engine Cylinder Piston Bush Guide Sleeve

Weifang Shengao Machinery Co., Ltd.- Warranty:as Specification

- Condition:New

Base Info

- Model NO.:WF-JF

- Certification:CE, RoHS, GS, ISO9001

- Standard:DIN, ASTM, GOST, JIS, ANSI

- Customized:Customized

- Material:Aluminum

- Application:Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery

- Item:CNC Manufacturer High Precision CNC Machining Part

- Supply:Drawing Design

- Quality Control:100% Inspected

- Shape:All Kinds of CNC Machining Parts

- Advantages:Delivery on Time, According to The Demand for Mat

- Delivery:Within 20 Days After Receiving Last Confirm Inform

- Machining:CNC

- Brand Name:Customized

- Shipping Port:Qingdao Port

- Business Type:Factory

- OEM Service:Yes

- Custom Made:Yes

- Logo Printing:Customized

- MOQ:10-1000PCS

- Free Sample:Yes

- Transport Package:Plywood Box

- Specification:SGS, ISO9001: 2008, ASTM, GB, DIN, EN124

- Trademark:Shengao

- Origin:Weifang City, Shandong Province, China

- HS Code:87089910

- Production Capacity:50000PCS,Year

- Package size per unit product:20.00cm * 50.00cm * 30.00cm

- Gross weight per unit product:15.000kg

Description

CapacityCNC turning work range: φ0.5mm-φ150mm*300mm CNC milling work range: 510mm*1020mm*500mm

Inspections:

3D instruments, 2D instruments, Projectors, Height Gauges, Inner diameter dial indicators, Dial gaues, Thread

and Pin gauges, Digital calipers,Micro calipers, Thickness testers, Hardness testers Roughness testers, etc.

( Detection accuracy to 0.001 millimetre )

1. High skilled and well-trained working team under good management environment;

Advantages:

1. Over 7 years factory experience

2. High quality control, Competitive price, Fast delivery

3. Small quantity acceptable

4. Sample and drawing available

5. OEM workable

6. One-stop service

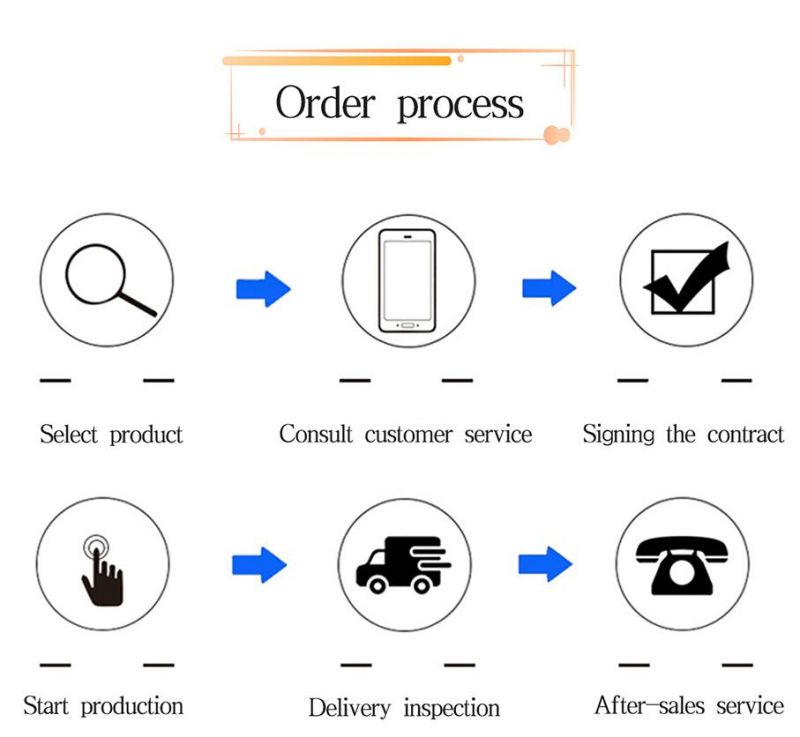

How to order Customized CNC Machine Center Cutting/Milling Machining Parts for Truck:

How to order Customized CNC Machine Center Cutting/Milling Machining Parts for Truck:

* You send us drawing or sample

* We carry through project assessment

* We give you a design

* You think the design is ok

* We make the sample and send it to you

* You think the sample is good then place an order and pay us 30% deposit

* We start to make the product

Inspections:

3D instruments, 2D instruments, Projectors, Height Gauges, Inner diameter dial indicators, Dial gaues, Thread

and Pin gauges, Digital calipers,Micro calipers, Thickness testers, Hardness testers Roughness testers, etc.

( Detection accuracy to 0.001 millimetre )