China Supplier 3m Width CNC Welded Wire Mesh Machine (XM-45)

Anping Xingmao Metal Wire Mesh Co., Ltd.- Type:Welded Wire Mesh Machine

- Wire Diameter:2.5-6mm

- Longitude Wire Space:50-300mm

- Cross Wire Space:Min.25mm,12.7mm

- Mesh Width:Max.2.5m

- Mesh Length:Max.6m

Base Info

- Model NO.:XM-45

- Welding Speed:50-75 Times,Min

- Certificate:ISO, BV and Ce Certification

- Welding Transformer:125kVA*6PCS

- Longitude Wire Feeding:Pre-Cut

- Welding Electrodes:48PCS

- Transport Package:by Wooden Box or Container

- Specification:2.5-6mm wire dia,width: max.2.5m,length: max.6m

- Trademark:XINGMAO

- Origin:Anping, China

- HS Code:8515809090

- Production Capacity:5PCS , Month

Description

Basic Info.

Model NO. XM-45 Welding Speed 50-75 Times/Min Certificate ISO, BV and Ce Certification Welding Transformer 125kVA*6PCS Longitude Wire Feeding Pre-Cut Welding Electrodes 48PCS Transport Package by Wooden Box or Container Specification 2.5-6mm wire dia,width: max.2.5m,length: max.6m Trademark XINGMAO Origin Anping, China HS Code 8515809090 Production Capacity 5PCS / MonthProduct Description

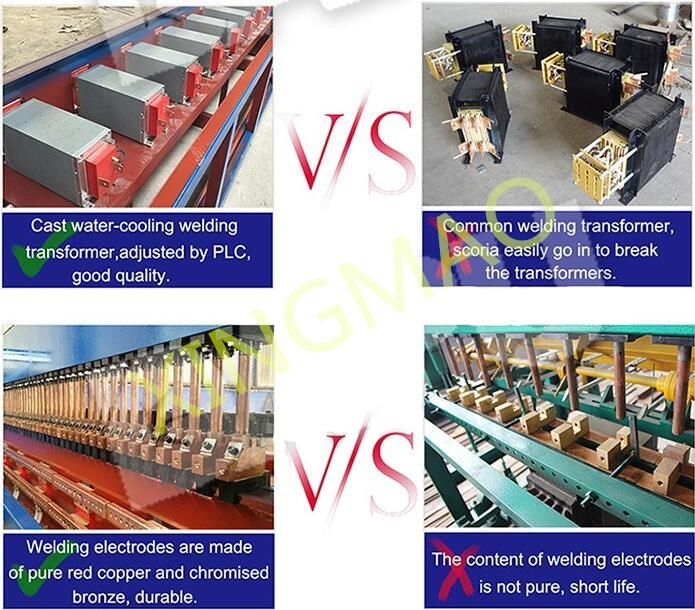

WELDED WIRE MESH MACHINE / WIRE MESH FENCE PANEL MACHINE/ WELDING MESH MACHINEThis machine adopts synchronous control technique,welding time and sub-control welding is composed of PLC program system.Touch screen and keyboard input panel forms make operation more intellectualized and reasonable. The biggest advantage of this system is that more than 30 kinds of different mesh size can be welded on the same panel. New and high efficiency of welding machine transformer expands welding wire diameter scope. Easy handling and high flexibility and high working efficiency achieve a perfect welding machine.

Production process : It needs the mesh welding machine to produce welded wire mesh panel ,and then use the bending machine to bend two mesh sides in 90 degree

Main Features

1. It can change the line wire space by adjusting the welding copper space .The weft wire space can be changable by PLC touch scree

2.The Welding Machine welds the horizontal and vertical wires to form a steel wire mesh. Mesh Width: 1200mm, Grid size: 50 x 50mm or 50 x 100mm;3. PLC control system to automatically straightens, welds and cuts the steel wire;

4. The A type machine has the mechanical transmission system;

5. The B type machine makes use of the integrated pneumatic system to ensure that the operation is stable, high reliability and long life span of the equipment.

6. The horizontal steel wires use the integrated straightening and cutting system to ensure stable operation and high accuracy;

7. The Automatic Alarm Device is easy to operate and maintenance;

8. Will automatically cut the steel wire mesh according the pre-set mesh length.

Technical specification

| XM-120A-1 | XM-120A-2 | |

Input power | 380V 50Hz | 380V 50Hz | 380V 50Hz |

Max. width | 1200mm | 1200mm | 1000mm |

Line wire space | 50-200mm | 50-200mm | 100-200mm |

Cross wire space | 50-200mm | 50-200mm | 50-200mm |

Wire diameter | 1.5-2.5mm | 1.5-2.5mm | 1.5-2.0mm |

Rated capacity | 56kva*3 | 56kva*2 | 56kva*1 |

Welding point No. | 25 | 25 | 11 |

Motor power | 2.2KW | 2.2KW | 2.2KW |

Feed line wire | Coil wire | Coil wire | Coil wire |

Feed cross wire | Coil wire | Coil wire | Coil wire |

Cutting mesh | Automatic & Manual | Automatic & Manual | Automatic & Manual |

Welding speed | 45 times/min | 45 times/min | 45 times/min |

Weight | 2500kg | 2000kg | 1700kg |

Dimension(L*W*H) | 2500*1800*1400mm | 2500*1800*1400mm | 2500*1800*1400mm |

PICTURES OF WELDED WIRE MESH MACHINE AS BELOW: