Automatic Hydraulic Thread Rolling Machine Screw Knurling Machine Factory

Xingtai Sichuang Machinery Manufacturing Co., Ltd.- After-sales Service:Fast Reply All Questions

- Type:Rolling Machine

- Forging Forming Method:Mold Forging

- Power Source:Hydraulic Pressure

- Feature:High Efficiency

- Certification:CCC, ISO9001, CE

Base Info

- Model NO.:Z28Series

- Warranty:12 Months

- Customized:Customized

- Advantage:Use Widely

- Condition:New

- MOQ:1PC

- Color:Customized

- Machine Name:Thread Rolling Machine

- Working Time:Adjustable

- Thread Pitch:Standard and Non-Standard

- Features:Bed Design, Good Rigidity

- Transport Package:Wooden Cases

- Specification:Multiple models

- Trademark:SiChuang

- Origin:Xingtai City, Hebei Province, China

- HS Code:8463200000

- Production Capacity:3000pieces,Year

Description

Basic Info.

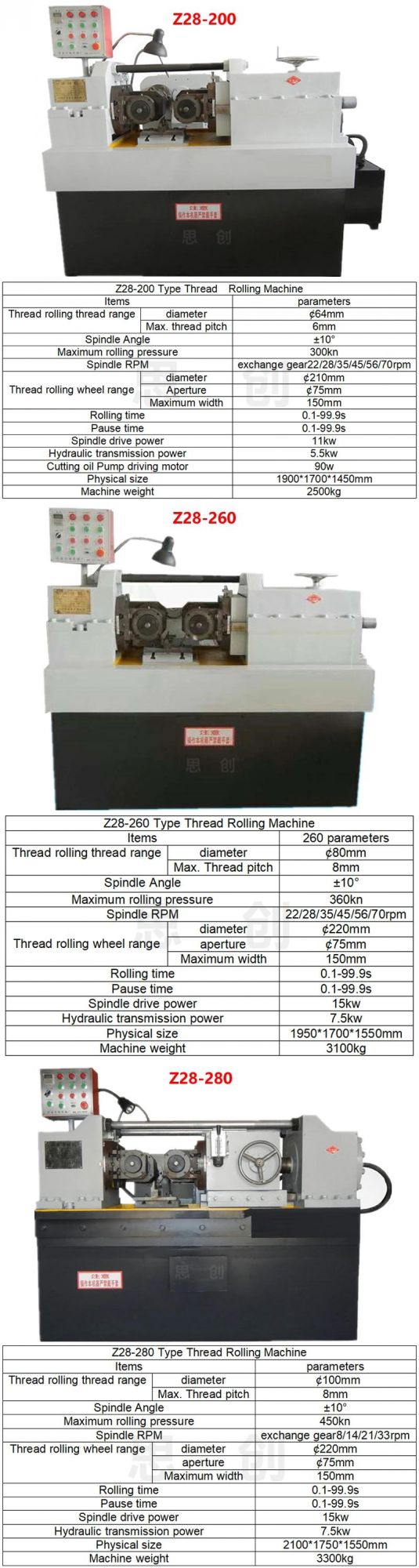

Model NO. Z28Series Warranty 12 Months Customized Customized Advantage Use Widely Condition New MOQ 1PC Color Customized Machine Name Thread Rolling Machine Working Time Adjustable Thread Pitch Standard and Non-Standard Features Bed Design, Good Rigidity Transport Package Wooden Cases Specification Multiple models Trademark SiChuang Origin Xingtai City, Hebei Province, China HS Code 8463200000 Production Capacity 3000pieces/YearProduct Description

Thread rolling machine is a multi-functional cold extrusion machine tool. The thread rolling machine can roll the workpiece with thread, straight grain and twill in cold state within its rolling pressure range; Rolling of spur, helical and helical spline gears; Straightening, reducing, rolling and various forming rolling. The machine has an electro-hydraulic execution and control system, which can select each working cycle in manual, semi-automatic and automatic modes. Wire rolling cold rolling process is a kind of non cutting processing, which can effectively improve the internal and surface quality of the workpiece. The radial compressive stress generated during processing can improve the fatigue strength and torsional strength of the workpiece. It is an ideal process with high efficiency, energy saving and low consumption.Wire rolling machine is divided into two axis wire rolling machine and three axis wire rolling machine.

1. Two axis wire rolling machine has strong advantages in hardware construction, auto parts, transportation and power, standard parts production, etc;

2. In the pipe thread processing industry, the three-axis thread rolling machine has equal triangular support to ensure true roundness, concentricity and perpendicularity.

How to properly maintain the wire rolling machine during operation:

1. The operator can only operate after passing the examination and obtaining the operation certificate. The operator should be familiar with the performance and structure of the machine and abide by the safety and shift handover system.

2. Before work, oil shall be injected in strict accordance with the lubrication regulations, and the oil quantity shall be appropriate, the oil circuit shall be unblocked, the oil mark (window) shall be eye-catching, and the oil cup shall be clean.

3. Check whether the fasteners at all parts are loose, whether the control mechanism is flexible and reliable, and whether the safety protection device is in good condition.

4. Before operation, start the machine tool for idling for 5min - I omin, and start operation only after confirming that the lubrication, hydraulic, electrical system and transmission parts operate normally.

5. According to the process requirements of the machined parts, correctly select and install the thread rolling die, rolling die and straightening die, and correctly adjust the tooth position and end face of the thread rolling die and the taper of the thread of the machined parts. When machining large workpieces, try to shorten the span of the two fulcrum bearing seats of the fixed spindle and the movable spindle to improve the stiffness of the spindle; When cantilever rolling is used for processing small workpieces, the rolling pressure shall not exceed 58800n, and the width of wire rolling die shall not exceed 40mm

6. Always pay attention to the operation during work and keep the interlocking, limit, feeding and other mechanisms accurate and reliable. In case of any abnormality, timely check and handle it.

| Model NO. | Z28Series | Warranty | 12 Months |

| Customized | Customized | Advantage | Use Widely |

| Condition | New | Color | Customized |

| MOQ | 1PC | Working Time | Adjustable |

| Machine Name | Thread Rolling Machine | Features | Bed Design, Good Rigidity |

| Thread Pitch | Standard and Non-Standard | Transport Package | Wooden Cases |

| Trademark | SiChuang | Origin | Xingtai City, Hebei Province, China |

| Specification | Multiple models | HS Code | 8463200000 |

1.What about the payment term&price term?

As usual, we accept T/T as the payment term, and the price term FOB is ok.

2.Are you a trading company or a factory?

Xingtai Sichuang Manufacturing Co., Ltd. is a manufacturer in Hebei Province, China. we have specialized in we have specialized in crane&winch over 10 years, our high quality products were welcomed in many countries.

3.How do you make your price?

We make the price according to our comprehensive costing. And our price will lower than the trade company because we are manufacture.You will get competitive price and better quality.

4.How about the packing?

Outside Package: Wooden packing case as export standard ; Inside Package: Stretch film

5. What's the delivery time?

Usually, we will delivery the goods within 15-20 working days, but this is aim at 1-10 pieces products, if more quantity, it depends.

6. Questions before quotation?

Capacity? Lifting height? Voltage? Quantity? The more details the more accurate price quotation. Thank you.

7.what about our winches features?

1, Compact structure and reasonable design

2, Easy to install, operate and maintenance

3, Low noise and good working condition

4, Three-phase power supply, suitable for a wide range of applications

5, Simple structure, easy to identify the cause of the failure, easy to repair and maintain