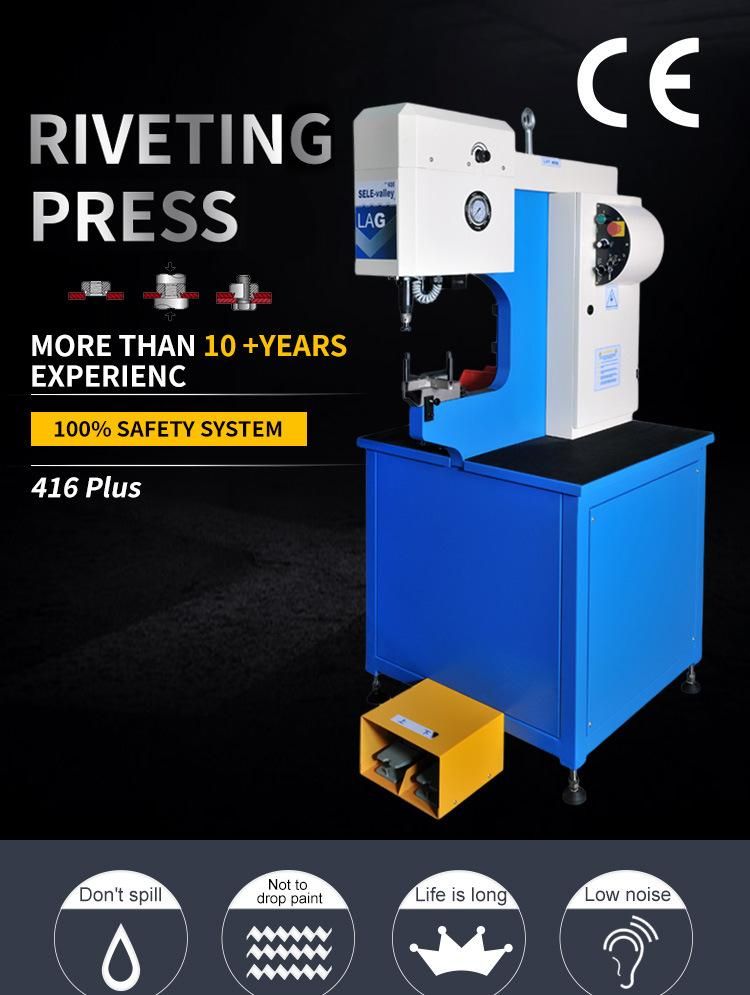

Intelligent Digital Variable Voltage Sheet Metal Riveting Machine

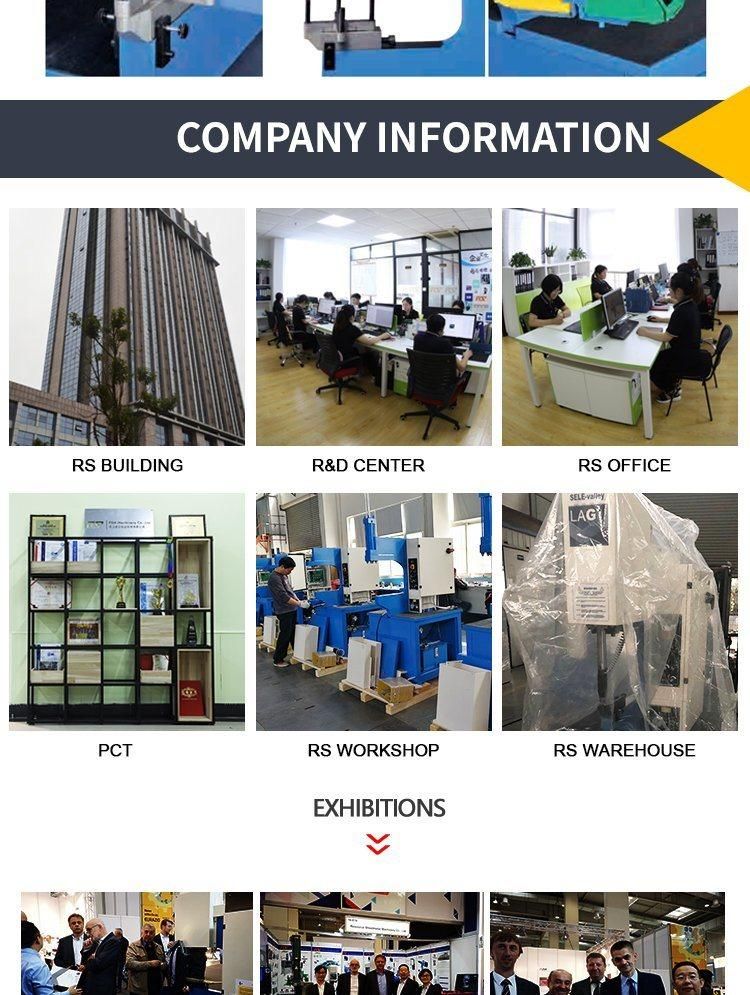

RSM Machinery Co.,Ltd.- After-sales Service:Online Support

- Automatic Grade:Automatic

- Power Supply:Hydraulic Pressure

- Warranty:1 Year

- Certification:CE

- Color:Red,Grey, Blue,White

Base Info

- Model NO.:416 Plus

- Force:44kn

- Throat Depth:406mm

- Throat Height:340mm

- Main Power:1.5kw

- Number of Insert Per Hour(Manually):1200

- Tank Capacity:38L

- Weight:350kg

- Dwell Time:No

- Transport Package:Wooden Package

- Specification:1.28*1.1*2.1m

- Trademark:RSM

- Origin:Shanghai, China

- HS Code:8463900090

- Production Capacity:25sets-30sets,Month

Description

Main Options

1,How to choose BTM tooling?

Specify your joint parts material, thickness, drawing and supply min 10pcs sample to make the testing.

2,What is the function of Forward Limited?

Forward limited function is designed to protect both the tooling and workpiece from damage by positive stop cylinder.

3,How to choose Automatic tooling system?

For nut, either bottom or upper delivery; for standoff/stud, upper delivery. Please send at least 300pcs samples for us to make

the testing.

4,Is it Automatic tooling system stable?

Yes, the automatic tooling system include high quality vibration bowl and intelligent digital variable voltage and variable

frequency Piezoelectric vibration feeder controller

FAQ

1,What size of nuts could fastener insertion 416/618/824 machine could press?

For the nuts/standoff/stud,we can make the press M3-M12.

2,If we have bought the manual fastener insertion, could we update to automatic machine easily?

Absolutely yes.

3,What is the difference between hydraulic fastener insertion machine and RSM fastener insertion machine?

Hydraulic drive is with energy saving and environment protection, if can reduce energy consumption by about 40% relatively

pneumatic drive.

4,What is the Manual tooling package made of? And What is the function of the Manual tooling package?

33 pieces of manual work with nuts/studs/standoff different size of punch and dies M2-M8, length up to 35mm, special insertion

application for small parts flange die holder and Manual J frame.

5,What is the main function of the fastener insertion machine?

Fastener insertion machine with the technology to provide strong, reusable and permanent the threads and mounting points in thin

sheet metal.

6,What quick-wear part does Fastener insertion machine has?

Fuse, safety switch, relay, oil filter, die holder handle.

Notice:

This picture demonstrates the anti-pressure hand function of the machine refers to the special security mode of processing,

only for reference, prohibited imitation