Metal Surface Pickling Fluxing Pre-Treatment Tank for Hot DIP Galvanizing Production Line

Hebei Annuo Automation Technology Co., Ltd.- After-sales Service:Long Life

- Warranty:Long Life

- Type:Coating Production Line

- Coating:Galvanized

- Substrate:Steel

- Certification:CE, ISO, SGS

Base Info

- Model NO.:HDG-A

- Condition:New

- Material:PP or Granite

- Temperature:45 -100 Deg C

- Capacity:Customized

- Application:Metal Surface Rust Removal

- Degrease Tank:Available

- Acid Pickling Tank:Available

- Fluxing Tank:Available

- Rinsing Tank:Available

- Transport Package:Container or Wooden Package

- Specification:customized

- Trademark:Annuo

- Origin:Shijiazhuang China

- HS Code:39269090

- Production Capacity:50000 Sets,Year

Description

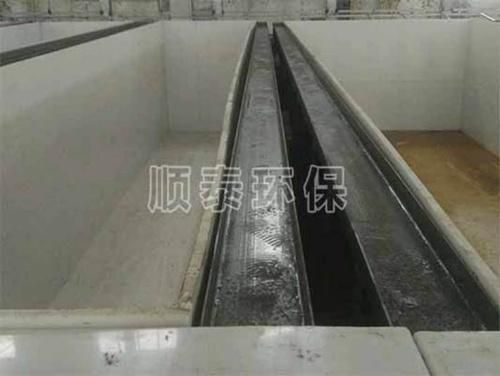

PP Plate with steel frame support

Performance characteristics:

1. Operating temperature is 10 ~100°C.

2. Strong corrosion resistance, convenient operation, long service life;

3. Light weight, easy to transport and install;

4. Simple and convenient to maintain.

5. Applicable Media: almost all of the inorganic medium and most organic solvents.

2nd the Granite plate material pickling tanks

Feature:

1. Easy to manufacture and construct, reliable quality, durability and high functionality.

2. Flexible settings,easy for maintenance.

3. Crashworthiness, acid and alkali resistance.

4. Operating temperature is 10 ~100°C.

5. Strong corrosion resistance, convenient operation, long service life.

6. Light weight, easy to transport and install.

7. Simple and convenient to maintain.

8. Applicable Media: almost all of the inorganic medium and most organic solvents.

3rd For the worker health, we can build the fully closed pickling room

The HCL acid mist will be abosorbed via acid mist scrubber tower, it will not leak any more. PLC control the galvanizing hoist lift and down the black workpiece into and out the pickling tanks. Whole process is automatilly. The worker can control out off the closed pickling room.

Acid mist srubber

Galvanizing Electric hoist

Factory Honor

Certificates:

All products are CE Authentication