Qualified Hydraulic Shearing Machine, Guillotine, Cutting Machine

Nanjing Dura Machines Co., Ltd.- Customized:Customized

- Layout:Vertical

- Cutting Material:Carbon Steel, Iron, Aluminum, Metal Alloy, Stainless Steel

- Automatic Grade:Automatic, Manual, Semi-Automatic

- Power Source:Hydraulic Pressure

- Cutting Mode:Hydraulic

Base Info

- Model NO.:DRGS series shearing machine

- Warranty:3 Years

- After-Sales Service Provided:Engineers Available to Service Machinery Overseas

- Certification:Ce,ISO,SGS

- Control System:According to Customer Requirements

- Feature:Plate Shearing Machine

- Electrical Supply:380V,50Hz,3pH(220V,60Hz,3pH Available)

- Cutting Angle:Adjustable

- Material Blade Shears:6crw2si

- Name:Hydraulic Shearing Machine

- Cutting Stroke:Adjustable

- Transport Package:Wooden Package

- Specification:Hydraulic Guillotine Shearing Machine, shearing

- Trademark:DURAMA

- Origin:Nanjing

- HS Code:84623990

- Production Capacity:200 Sets

Description

Basic Info.

Model NO. DRGS series shearing machine Warranty 3 Years After-Sales Service Provided Engineers Available to Service Machinery Overseas Certification Ce,ISO,SGS Control System According to Customer Requirements Feature Plate Shearing Machine Electrical Supply 380V,50Hz,3pH(220V,60Hz,3pH Available) Cutting Angle Adjustable Material Blade Shears 6crw2si Name Hydraulic Shearing Machine Cutting Stroke Adjustable Transport Package Wooden Package Specification Hydraulic Guillotine Shearing Machine, shearing Trademark DURAMA Origin Nanjing HS Code 84623990 Production Capacity 200 SetsProduct Description

CNC / NC Shearing Machine/Hydraulic Guillotine Shearing Machine, Shears, Plate Shearing Machine/ Steel Plate Cutting Machine

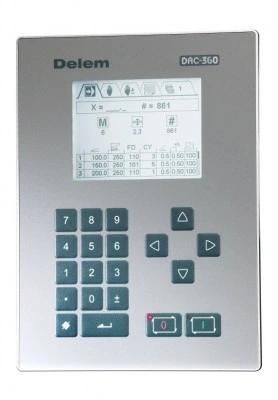

DAC360 CNC Guillotine Shear DRGS series (QC11K-series)

The model of this DAC360 cnc guillotine shear is DRGS series (QC11K-series) ,Adjustable rake angle to reduce the distortion and deformation of the metal sheet;DAC360s CNC from Holland Delem is the advanced controller for matching with guillotine shear.

Basic features for DAC360 cnc guillotine shear:

• Advanced generation of hydraulic plate shear

• Total steel welded structure,stress eliminated to ensure necessary rigidity and reliability

• Structure of three pairs of rail and trolley eliminates the bearing clearance so as to improve shearing results

• Hand wheel blades gap adjustment with indicator,rapid,convenient and accutate

• Top blade could be adjusted to work for full stroke or shorter ones

• DAC360s CNC from Holland Delem is the advanced controller for matching with guillotine shear

• DAC360s will control the position of backgauge,cutting stroke,rake angle,blade clearance,repeat times of steps etc

• Transfer balls on table and front support arms for easy feeding

• Adjustable rake angle to reduce the distortion and deformation of the metal sheet

• Inchlining structure of the upper blade holder for easy blanking and high cutting precision

• Customized power connection voltage, such as 3phase, 220V, 60Hz in South Ameirca,etc

DAC360 cnc guillotine shear optional elements:

Cut piece sliding slope

Light curtain for hand safety

Wind turbine coolant

Technical Parameters:

| Model | Cutting thickness (mm) | Cutting width (mm) | Shearing angle | Strokes (min-1) | Backgauge range (mm) | Main Motor (kw) | Weight (kg) | Overall Dimensions L×W×H(mm) |

| Modelo | Capacidad de corte (mm) | Logitud de corte (mm) | angulo | Golpes per minuto (min-1) | Tope trasero (mm) | Potencia motor (kw) | Peso aprox. (kg) | Dimensiones L×W×H(mm) |

| DRGS-625 | 6 | 2500 | 0.5-2 | 10-25 | 20-600 | 7.5 | 5,000 | 3270×1580×2040 |

| DRGS-632 | 6 | 3200 | 0.5-2 | 10-25 | 20-600 | 7.5 | 6,400 | 3820×1580×2100 |

| DRGS-640 | 6 | 4000 | 0.5-2 | 10-25 | 20-600 | 7.5 | 8,500 | 4620×1630×2160 |

| DRGS-650 | 6 | 5000 | 0.5-2 | 8-20 | 20-800 | 7.5 | 13,000 | 5530×2075×2080 |

| DRGS-660 | 6 | 6000 | 0.5-2 | 8-20 | 20-800 | 11 | 17,000 | 6530×2075×2610 |

| DRGS-670 | 7 | 7000 | 0.5-2 | 10-25 | 20-800 | 11 | 21,000 | 7530×2075×2830 |

| DRGS-825 | 8 | 2500 | 0.5-2 | 10-25 | 20-600 | 11 | 5,500 | 3270×1580×2040 |

| DRGS-832 | 8 | 3200 | 0.5-2 | 6-20 | 20-600 | 11 | 6,500 | 3820×1580×2100 |

| DRGS-1225 | 12 | 2500 | 0.5-2.5 | 6-20 | 20-800 | 18.5 | 11,000 | 3400×1920×2350 |

| DRGS-1232 | 12 | 3200 | 0.5-2.5 | 6-20 | 20-800 | 18.5 | 12,000 | 3950×1920×2400 |

| DRGS-1240 | 12 | 4000 | 0.5-2.5 | 4-15 | 20-800 | 18.5 | 14,000 | 4750×1960×2580 |

| DRGS-1380 | 13 | 8000 | 0.5-2.5 | 5-15 | 20-800 | 30*2 | 52,000 | 8600×2900×3100 |

| DRGS-1625 | 16 | 2500 | 0.5-2.5 | 5-15 | 20-800 | 18.5 | 11,000 | 3450×2010×2350 |

| DRGS-1632 | 16 | 3200 | 0.5-2 | 5-15 | 20-800 | 18.5 | 12,800 | 3940×1960×2400 |

| DRGS-1640 | 16 | 4000 | 0.5-2.5 | 5-15 | 20-800 | 18.5 | 15,300 | 4745×2010×2640 |

| DRGS-2025 | 20 | 2500 | 0.5-3 | 5-15 | 30-800 | 30 | 14,000 | 3450×2200×2560 |

| DRGS-2040 | 20 | 4000 | 0.5-3 | 4-15 | 30-800 | 37 | 21,000 | 4660×2200×2710 |

| DRGS-2525 | 25 | 2500 | 0.5-3.5 | 4-15 | 40-1000 | 37 | 17,000 | 3450×2700×2900 |

Company Information:

We are DURAMA, durable machines and spare parts supplier, the designers and manufacturers of industry products. Our factories are located in industrial area in Nanjing City. With over 10 years of experience, DURAMA supplies the most comprehensive range of machines and spare parts available today.

With continued investment and an unrivaled reputation for quality and service, DURAMA is trying to be the global center of excellence for Press Brake Tools and bending technology. We also supply relative industry machines and materials.

DURAMA is always trying best to supply durable machines and spare parts, and timeproof service to our customers.

Our Services:

1.Pre-sales:help client select the suitable machine

2.After-sales:provide free technical guidance

3.Installation service:we dispatch technician to customer's factory for installation

4.Training service:offer training of how to use our machines

5.Quality guarantee:machine warranty is 3 years, We offer flexible extended warranties if needed.

6.we arrange final test before shipment

7.Other services :

1): response within 1 hours

2): provide solution in 1 day

3): solve complaint in 2 days

Packaging and Shipping:

Standard Exporting Packaging for DURAMA Shearing Machine

1.inner machine, it is packaged in moistureproof film.

2.pallet or wood box.

3.ground fixed bolt to confirm steady and avoid destory.

4.tightly exporting standard belf to fasten machine in container.

How to reach our factory:Our factory is about 260 km far away from Shanghai air port, and 8 km far away from Nanjing air port . You can come here by fast train or by plane to Nanjing. We will pick you up from the train station or air port.

If you would like to know some more details about this product, please leave a message with your contact information, we will reply you at earliest time!

Welcome to our website:http://durama.en.made-in-china.com