Dsihed End Flanging Machine

Nantong Zhenhuan Trade Co., Ltd.- Structure:Vertical

- Pressure Supply Type:Hydraulic Pressure

- Spinning Direction:Reverse

- Metal Material:Steel

- Spinning Deformation Condition:Cold Spinning

- Spinning Wheel Number:Double

Base Info

- Model NO.:3000x16mm

- Finished Product:Tank Head

- Max. Dished End Diameter:3000-10000mm, as Required

- Max. Dished End Thickness:12-80mm, as Required

- Control Type:PLC, Omron From Japan

- Raw Material:Carbon Steel

- Carbon Steel:Cold Forming Way for Thickness Below 40mm

- Automatic or Not:Automatic

- Ominal Force of Main Cylinder:6000-16000kn, Accdoring Head Diameter and Thicknes

- Main Motor Power:75-150kw, Accdoring Head Diameter and Thickness

- Rollers Material:35CrMo, or Customized

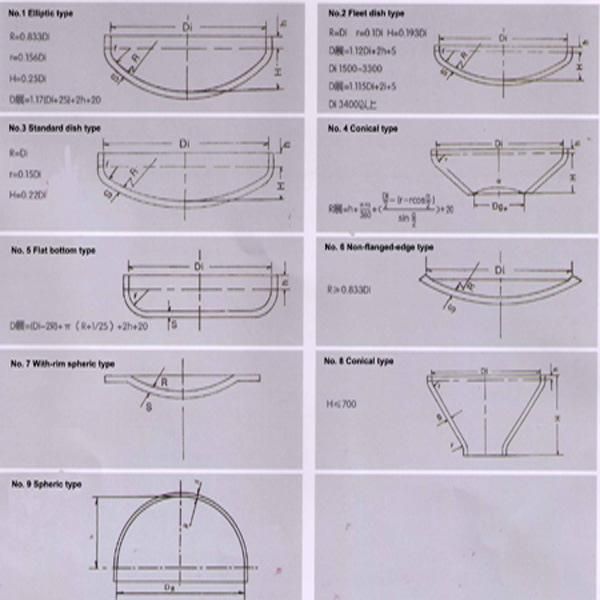

- Dish Ends Kinds:Ellipse, Dish, Taper, Sphericity, etc

- Transport Package:Suitable for Shipment

- Specification:SGS

- Trademark:Zhenhuan

- Origin:China

- Production Capacity:10 Sets Per Year

Description

Basic Info.

Model NO. 3000x16mm Finished Product Tank Head Max. Dished End Diameter 3000-10000mm, as Required Max. Dished End Thickness 12-80mm, as Required Control Type PLC, Omron From Japan Raw Material Carbon Steel Carbon Steel Cold Forming Way for Thickness Below 40mm Automatic or Not Automatic Ominal Force of Main Cylinder 6000-16000kn, Accdoring Head Diameter and Thicknes Main Motor Power 75-150kw, Accdoring Head Diameter and Thickness Rollers Material 35CrMo, or Customized Dish Ends Kinds Ellipse, Dish, Taper, Sphericity, etc Transport Package Suitable for Shipment Specification SGS Trademark Zhenhuan Origin China Production Capacity 10 Sets Per YearProduct Description

Dished end flanging machine is for tanks and vessels, max.diameter 10000mm, max. thickness 80mm.

Dished end flanging machine can produce various kinds of dished ends, such as ellipse, dish, taper, sphericity, big scale canister distortion forming.

Dished Pressing is the first step.

The piston of main cylinder moves up and down to drive upper tool to press the raw plate to become required concave shape.

There is one manipulator mounted inside the frame. It will move, rotate and incline the workpiece.

Dished Flanging is the second step. Adopting spinning principle, this machine will make blank workpiece from drum machine into ellipse end, dish end, sphericity end, flat-bottom or taper-bottom end, etc.

The structure is closed frame type, good rigidity. The spinning speed is stepless adjusted. And PLC control (Omron from Japan) makes operation easier.

Different diameter and thickness has different technical data, pls contact us for details.

Lily

T: 0086 152 6277 5225

Dished end flanging Machine picture

Below is the types which our dished end flanging machine could produce

Sales Turnover