Die Gravity Casting Machine

Delin Intelligent Technology Co., Ltd.- Control Type:CNC

- Customized:Non-Customized

- Condition:New

- Automatic Grade:Automatic

- Certification:CE, ISO9001

- Type:Sand Casting

Base Info

- Frontal of Casting:0-110

- Hydraulic Pressure:40-60kpa

- Dimension(L*W*H):2250X2160X1560mm

- Heaviest Weight of Mold:135kg

- Lateral of Casting:0-90

- Transport Package:Shipping

- Specification:1750KG

- Trademark:DL

- Origin:China

Description

1.Circuits are all controlled by PLC,data setting adopts touch screen ,electrical components are imported from Japan and hydraulic components are as well imported from outside.

2. For gravity model casting with brass and ferroalloy.

3. Front casting,lateral casting and secondary casting are optional.

4. Individual cooling time of model is adjustable.

5. The dismantling ,assembly and cleaning of model are convenient.

6. Two functions of manual and automatic circulation are available.Totalizing counter and preset counter are arranged to record the piece number of on duty production.

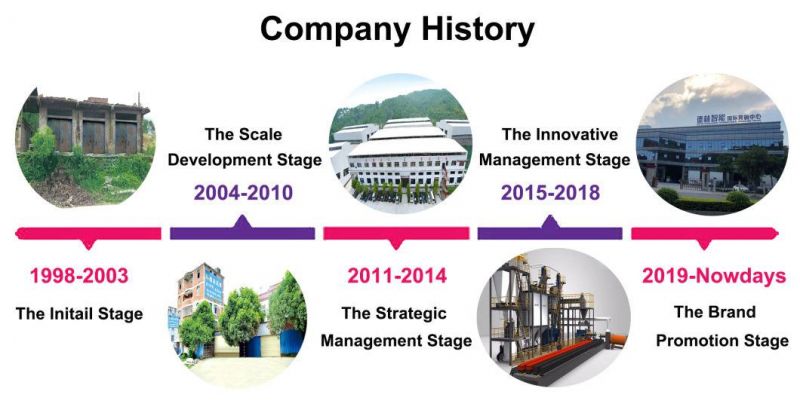

Delin Intelligent Technology Co., Ltd

1.We are one manufacturer of metal foundry machinery and CNC machining machinery in China.

Q1: Can I have your quotation?

A: First, please offer us the information of your material size, without these parameter, we are not able to recommend you the suitable machine.

Q 2: How to operate and maintain the machine?

A : First, we will provide a professional and detailed USER GUIDE to you with the machine; Second, we will debug the machine in the best status for you; At last, we also provide abroad technical training service.

Q 3: Where is your factory located ? How can I visit it ?

A : Our factory is located in Quanzhou city,Fujian province,China. You can fly to Jinjiang or Xiamen air port, we will pick you up.

Q 4 :What's dimension of your workpiece ?

A : In order to configure suitable size machine for you. we should get your info. We can professional design as your requirement.

Q 5: Can you guarantee you quality?

A : Of course. We are the manufacture factory ,more important, we put a high value on our reputation. Best quality is our principle all the time. You can be assured on our production completely.