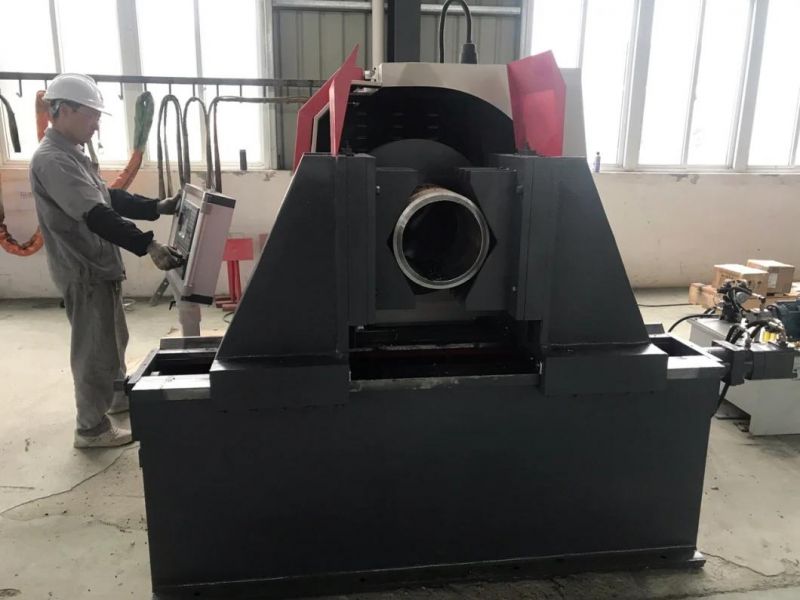

New Fast Pipe Beveling Machine, CNC Pipe/End Beveling Machine, Groove Machine

Shanghai Qianshan Piping Technology Co., Ltd.- After-Sales Service Provided:Engineers Available to Service Machinery Overseas

- Applicable Domain:Oil & Gas, Petrochemical, Powerplant, Offshore etc

- Control System:PLC with Human Machine Interface Touch Screen

- Purpose:Pipe End Beveling

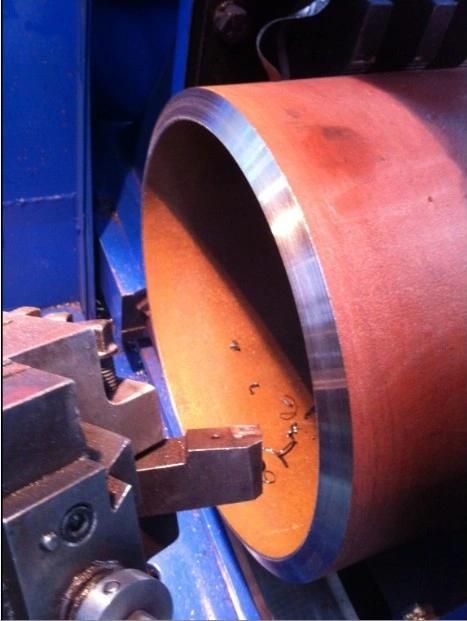

- Beveling Procedure:Tool Bits and Cold Beveling

- Voltage:380-440V±10%-3pH,50-60Hz

Base Info

- Model NO.:FPEBM-16C,24C,32C

- Bevel Type:U, J, V, X, Double V & Compound Bevel

- Color:Red or as Request

- Type:Pipe and Tube Bevelling Machine

- Application:Oil & Gas, Petrochemical, Refinery, Offshore

- Type for Cutting Machine:CNC Bevel Cutting Machine

- Type for Fold-Bending Machine:PLC Controller

- Automation:Automatic

- Transport Package:Sea Worthy Packing

- Specification:ISO9001, CE, SGS, TUV

- Trademark:QSPT

- Origin:Shanghai, China

- HS Code:8458110000

- Production Capacity:20 Sets,Month

Description

Basic Info.

Model NO. FPEBM-16C/24C/32C Bevel Type U, J, V, X, Double V & Compound Bevel Color Red or as Request Type Pipe and Tube Bevelling Machine Application Oil & Gas, Petrochemical, Refinery, Offshore Type for Cutting Machine CNC Bevel Cutting Machine Type for Fold-Bending Machine PLC Controller Automation Automatic Transport Package Sea Worthy Packing Specification ISO9001, CE, SGS, TUV Trademark QSPT Origin Shanghai, China HS Code 8458110000 Production Capacity 20 Sets/MonthProduct Description

New Fast Pipe Beveling Machine, CNC Pipe End Beveling Machine

Performance features

On-line performance: Good(designed as per the on-line equipment of the production line)

Beveling speed: ≤ 5min /pipe bevel (dn200 sch40)

Bevel cutting: Cutting a pipe with other equipment such as band saw and then machining each bevel.

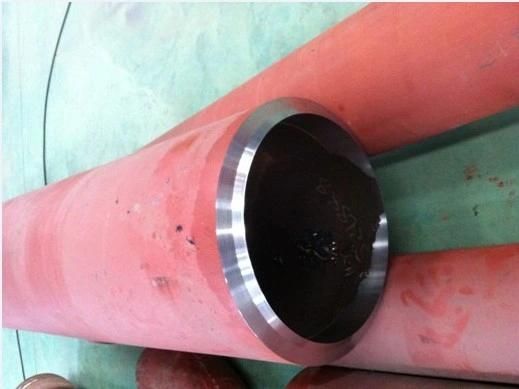

Bevel quality: Very good

Application: For machining the u or v shape bevels for numbers of pipes with heavy wall thickness

Technical parameters

Pipe diameter applicable: Dn50-400(Φ 57-426)/ dn100-600(Φ 114-610)/ dn200-800(Φ 219-813);

Pipe wall thickness applicable: 4-90mm; 6-180mm

Materials applicable: Carbon steel, alloy steel, stainless steel and cryogenic steel, ect.

Bevel shape: U, x, v and double v

Driven by: Motor

Clamping system: Work piece is clamped by hydraulic cylinder & centering automatically

Bracket system: Screw lifting adjustable

Rev of the principal axis: Stepless speed control & variable frequency

Axial displacement: 80mm(principle axis) 100mm(machine head); 150mm(principal axis), 300mm (machine head)

Bevel angle of tool rest: 0° ~45°

Widthwise displacement: ± 50mm; ± 100mm

Control system: PLC controlling; CNC controlling

| 1 | Pipe Diameter Applicable | DN50-400/DN100-400/DN200-800/DN200-600 |

| 2 | Wall Thickness | 4-90mm;6-180mm |

| 3 | Material Applicable | C.S,S.S, Alloy Steel, Cryogenic steel, etc. |

| 4 | Bevel Shape | U,X,V,and Double V |

| 5 | Control System | PLC, CNC |