OEM High Precision CNC Machining of Spring Clip in Black Anodizing

Ningbo ACE BEST Machinery Co., Ltd.- Condition:New

- Certification:CE, RoHS

- Standard:ASTM

- Customized:Customized

- Material:Alloy

- Application:Metal Processing Machinery Parts

Base Info

- Name:Carbon Steel CNC Machining Part for Auto Parts

- Size:Customized

- Work:CNC Machining

- Quality Control:Measuring Tool

- Tolerance:+,-0.005mm

- Company Location:Ningbo

- Sample Time:7-10days

- Machine:CNC Lathe

- Transport Package:Safe Export Carton

- Specification:RoHs

- Trademark:ACE

- Origin:Ningbo, Zhejiang

- HS Code:7616999000

- Production Capacity:Carbon Steel High Precision CNC Machining: 50K,M

Description

Drawing Format Can Done By Ace?

dwg, dxf, prt, iGS, step, stp, iges, slprt, asm, x_t files are all accepted.

What kinds of CNC machining product is suitable to send to Ace for quoation?

CNC machining product, CNC milling product, CNC lathing product, CNC turning product, CNC precision machining product, maching product, precision product and all machining parts used in different industrials such as: spray nozzle, car accessories, railway accessories, bathroom accessoires, equipemnt spare parts, pipe and fittings and so on.

How Ace Sure The Quality?

1) Ace proceed 4 times during production proceeding.

They are: raw material inspection, process machining inspection, mass production inspection, final inspection.

3)100% Inspected before Shipment. Inspection date report provided. And PPAP can be provided too.

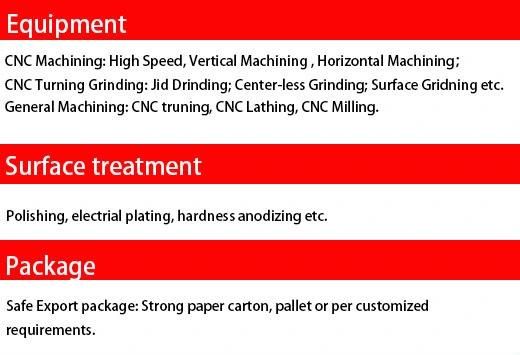

How Many Equipments Does Ace Have?

10 CNC lathing machine with actual working tolerance ±0.02MM.

5 CNC lathing and milling center with actual working tolerance is ±0.02MM.

ACE have gain expertise in providing Precision Machinery Job Works that are widely used in many industries to add new life to the machines. These job works are executed by our experienced professionals making optimum utilization of modern tools and equipment. Our innovative approaches to lend new life to old machines enabled us to gain a remarkable position in industry. Customers can avail these job work from us as per their needs.

Our company is recognized by features of "Precise Finish, Accurate Dimensions, Abrasion & Corrosion Resistance,Robustness."

We hope to cooperate with you and develop together!2

IQC → IPQC → OQC/FQC → Quality Complain Feedback → Audit & Training.