Stabilizing Roller Used for Continuous Hot DIP Galvanizing Line to Get High Qualified Galvanized Products

Yantai Fangle Metallurgy Group Co., Ltd.- Condition:New

- Certification:CE, ISO9001

- Standard:DIN, ASTM, GB

- Customized:Customized

- Material:Stainless Steel

- Application:Metal Processing Machinery Parts

Base Info

- Model NO.:as the drawing

- Transport Package:Woodern Case

- Specification:Export package

- Trademark:FANGLE

- Origin:China

- Production Capacity:20000tons,Year

Description

Basic Info.

Model NO. as the drawing Transport Package Woodern Case Specification Export package Trademark FANGLE Origin China Production Capacity 20000tons/YearProduct Description

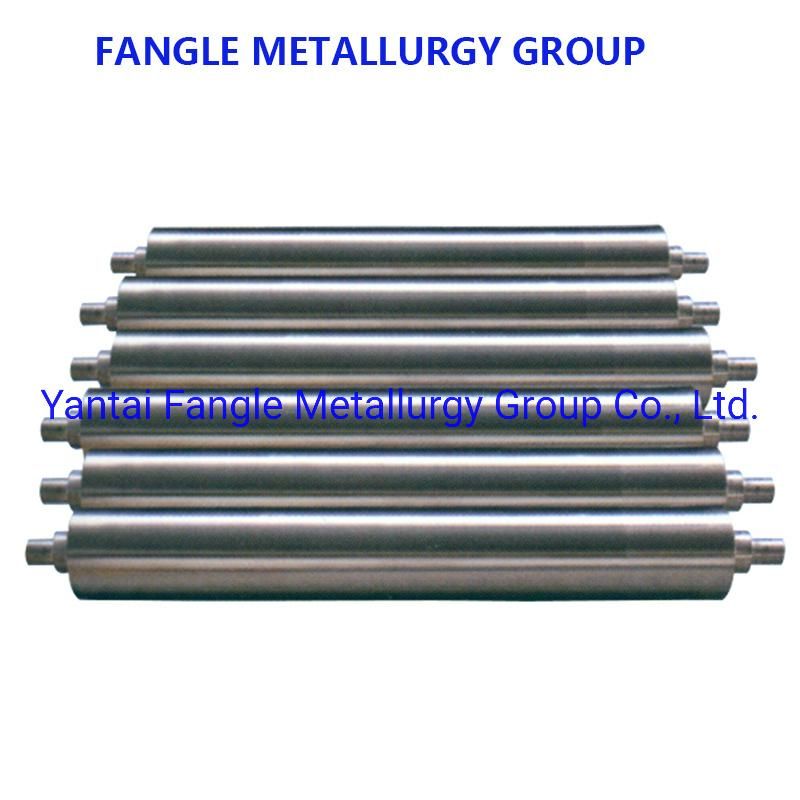

Stabilizing roller Used for Continuous Hot DIP Galvanizing Line to get high qualified galvanized productsDescription

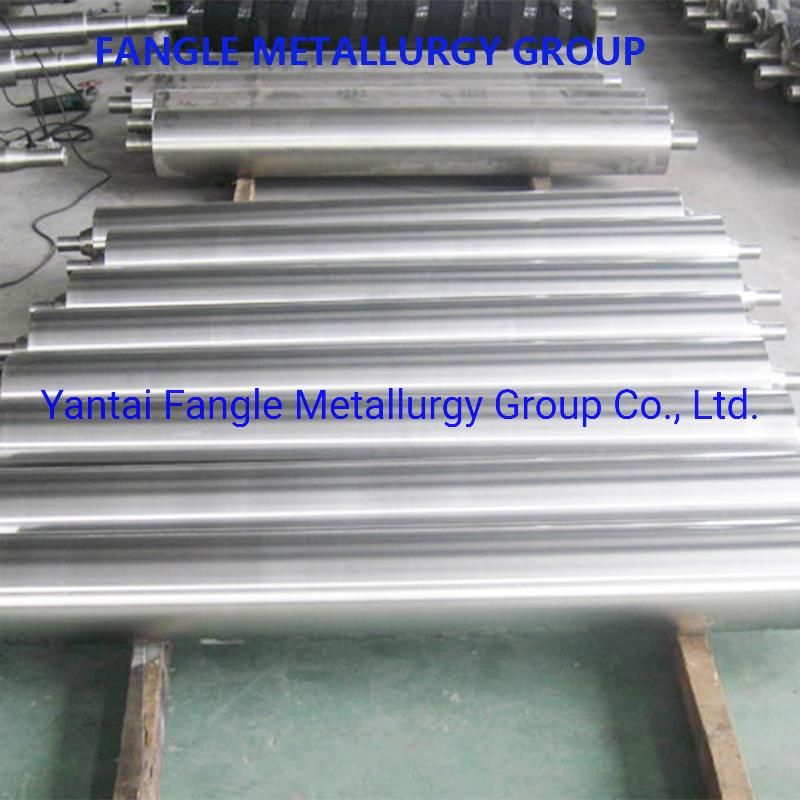

In the metallurgy industry, in order to get high qualified galvanized products, stabilizing roller, also called stabilizer roller plays very important role in the continuous hot dip galvanizing line. Stabilizer roller is one of the three rolls in CGL (continuous galvanizing line); Along with other two rolls, sink roller and back-up roller, they are the main composition of continuous galvanizing line. We usually call them as "three rolls" in galvanizing production line. The rollers quality directly impact the finished products quality and its service life.

Working condition : Working temperature is 500ºC-700ºC. Cooperated with stabilizer roll, agitating molten zinc liquid to the surface of plate. The surface structure and quality of the sinking roller will directly affect the galvanizing quality of the sheet and affect its service life. Therefore, the sinking roller is one of the key factors determining the production quality and production efficiency of the galvanizing line.

Products show

Customer Visit