Schneider Electric Guillotine Sheet Metal Cutting Machine 12*3200mm

Maanshan Middle Asia Machine Tools Manufacture Co., Ltd.- Customized:Customized

- Layout:Coaxial

- Cutting Material:Carbon Steel, Iron, Aluminum, Stainless Steel

- Automatic Grade:Automatic

- Power Source:Hydraulic Pressure

- Cutting Mode:Saw Cutting

Base Info

- Model NO.:QC12K 12*3200mm

- Dimension(L*W*H):3840*1610*1620

- Weight:5000kg

- Warranty:12 Momthes

- Main Motor( Kw):7.5

- Place of Origin:Anhui, China (Mainland)

- Voltage:380V,220V,415V

- Rated Power(Kw):15

- After Sale Service Provided:Overseas Third-Party Support Available

- Product Name:Hydraulic Metal Sheet Cutter Machine

- Color:Optional

- Transport Package:with Plasic Bag or According to The Customers′ Req

- Specification:3840*1610*1620

- Trademark:Hydraulic Metal Sheet Cutter Machine , Hydraulic G

- Origin:China

- HS Code:8462399000

- Production Capacity:50sets, Monthes

Description

Basic Info.

Model NO. QC12K 12*3200mm Dimension(L*W*H) 3840*1610*1620 Weight 5000kg Warranty 12 Momthes Main Motor( Kw) 7.5 Place of Origin Anhui, China (Mainland) Voltage 380V/220V/415V Rated Power(Kw) 15 After Sale Service Provided Overseas Third-Party Support Available Product Name Hydraulic Metal Sheet Cutter Machine Color Optional Transport Package with Plasic Bag or According to The Customers′ Req Specification 3840*1610*1620 Trademark Hydraulic Metal Sheet Cutter Machine / Hydraulic G Origin China HS Code 8462399000 Production Capacity 50sets/ MonthesProduct Description

Schneider electric guillotine sheet metal cutting machine 12*3200mm1. Digital Display

2. 1 year warranty

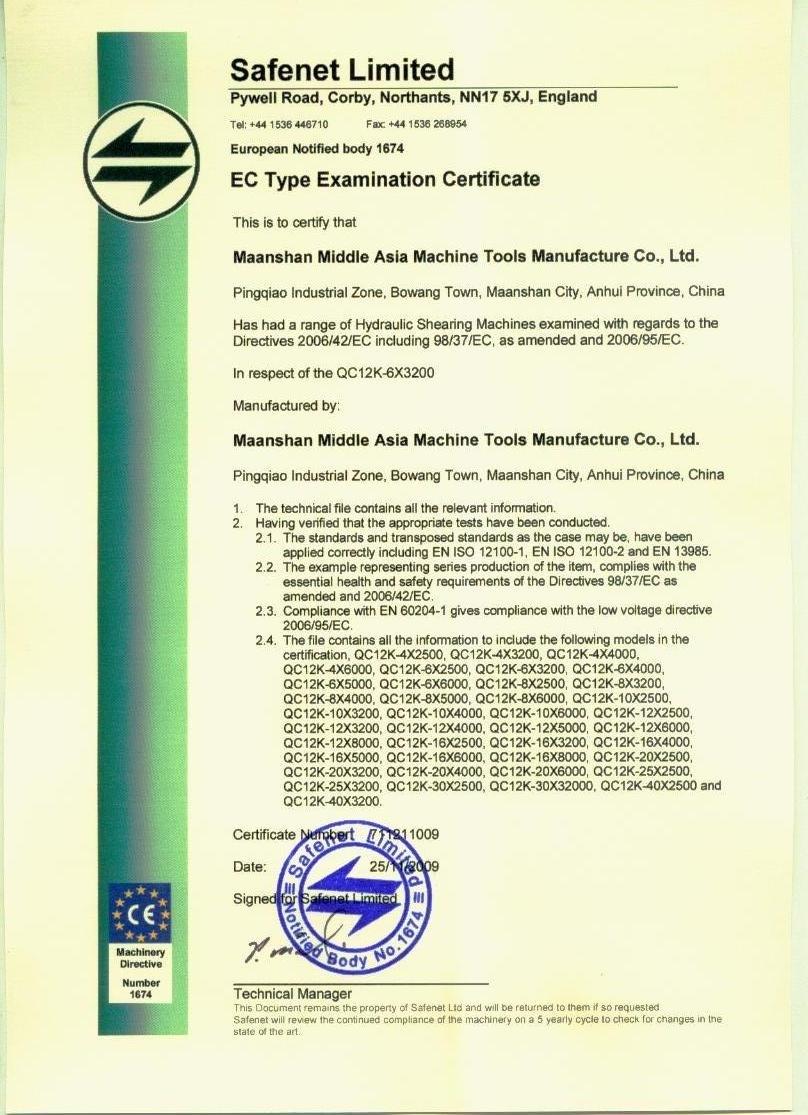

3. CE/ISO

4. Ball Lead Screw and Liner Guide for Opt

1. Front Operated Motorised Backgauge - Range 10 to 750mm;

2. Electro hydraulic variable rake angle adjustment 1° To 3° ;

3. Quick Blade gap adjustment by handle behind machine on both sides;

4. Individual pump and pressure setting for hydraulic holddowns;

5. Vickers double vane pump with individual pump for cutting and plate clamping;

6. Shadow line lighting and well design finger guard for clear view of cutting line;

7. Shear Blades - four sided, quality high-carbon high chrome blades D2 quality;

8. Manual inching mode for easy setting of Blades clearance;

9. Safety foot switch operation. Top blades will return to top position when foot is remove from foot pedal;

10. Hydraulic-full protection against overload through build-in safety valve;

11. 1 meter Side Squaring Arm with disappearing stops;

12. Ball screw and linde guide rail as optional for guarantee the higher precision;

13. Italy HT071 single axis controller as optional for customer choice.

Performance characteristic:

1.Steel plate welded structure,hydraulic transmission,accumulator return,convenient operation,reliable performance,beautiful appearance

2.Edge adjustment signs,adjust light and quickly,continuously variable transmit

3.Lighting device on the line,and continuously variable adjustment of upper tool carrier itinerary

4.Fence type safety protection device

5.Back gauge adopt E10 NC,low noise,high precision

Parameters:

Model | Cutting thickness (mm) | Cutting width (mm) | Cutting angle (°) | Backgauge range(mm) | Stroke number (times/min) | Main motor (kw) | Weight (kg) | Overall dimensions (L*W*H)(mm) |

4*2500 | 4 | 2500 | 1.5 | 20-400 | 10 | 5.5 | 3800 | 3040*1610*1620 |

4*3200 | 4 | 3200 | 1.5 | 20-600 | 10 | 7.5 | 5000 | 3840*1610*1620 |

4*4000 | 4 | 4000 | 1.5 | 20-600 | 8 | 7.5 | 6500 | 4600*1700*1700 |

4*6000 | 4 | 6000 | 1.5 | 20-600 | 5 | 11 | 11000 | 6460*2100*2300 |

6*2500 | 6 | 2500 | 1.5 | 20-600 | 10 | 7.5 | 5000 | 3040*1610*1620 |

6*3200 | 6 | 3200 | 1.5 | 20-600 | 9 | 7.5 | 6500 | 3840*1610*1620 |

6*4000 | 6 | 4000 | 1.5 | 20-600 | 8 | 7.5 | 8000 | 4620*1750*1700 |

8*2500 | 8 | 2500 | 1.5 | 20-600 | 10 | 7.5 | 6000 | 3040*1700*1700 |

8*3200 | 8 | 3200 | 1.5 | 20-600 | 8 | 7.5 | 7200 | 3860*1700*1700 |

8*4000 | 8 | 4000 | 1.5 | 20-600 | 8 | 15 | 8800 | 4640*1700*1700 |

10*2500 | 10 | 2500 | 1.5 | 20-600 | 9 | 15 | 7300 | 3040*1700*1700 |

10*3200 | 10 | 3200 | 1.5 | 20-600 | 9 | 15 | 8000 | 3860*2000*1700 |

10*4000 | 10 | 4000 | 1.5 | 20-600 | 8 | 18.5 | 12000 | 4650*2100*2000 |

12*2500 | 12 | 2500 | 1.5 | 20-800 | 9 | 18.5 | 9000 | 3140*2150*2000 |

12*3200 | 12 | 3200 | 1.5 | 20-800 | 9 | 18.5 | 10800 | 3880*2150*2000 |

12*4000 | 12 | 4000 | 2 | 20-800 | 8 | 18.5 | 13000 | 4680*2150*2000 |

16*2500 | 16 | 2500 | 2 | 20-800 | 9 | 18.5 | 11000 | 3140*2150*2000 |

16*3200 | 16 | 3200 | 2 | 20-800 | 8 | 18.5 | 13000 | 3880*2150*2000 |

16*4000 | 16 | 4000 | 2.5 | 20-800 | 8 | 22 | 16300 | 4650*2150*2200 |

20*2500 | 20 | 2500 | 2.5 | 20-800 | 8 | 30 | 15500 | 3440*2300*2500 |

20*3200 | 20 | 3200 | 2.5 | 20-800 | 8 | 30 | 18000 | 4510*2350*2700 |

20*4000 | 20 | 4000 | 2.5 | 20-800 | 5 | 30 | 21000 | 4850*2350*2700 |

25*2500 | 25 | 2500 | 3 | 20-800 | 5 | 37 | 19000 | 3200*2700*2900 |

25*3200 | 25 | 3200 | 3 | 20-800 | 5 | 37 | 23000 | 4200*2700*3000 |

30*2500 | 30 | 2500 | 3.5 | 20-1000 | 5 | 37 | 28000 | 3300*2900*3000 |

30*3200 | 30 | 3200 | 3.5 | 20-1000 | 5 | 37 | 33000 | 4200*2900*3200 |

Schneider electric guillotine cutting machine Q11Y 12*3200

More details:

Control system selection:

Related products:

Packaging & Shipping

(1)before packing,the machine tool will be testing for 48 hours to ensure all the equipment is 100% qualitied. (2)before loading,stable package,professional and skilled loader reduce damage of product during transport.(3)after loading,our professional documentary staff will follow the order till the product departs from port.

Company info:

Our Services

1.Shearing blades and accessories-Customized to your specifications

In our shearing blades, our focus is on first-class, practical, well-thought-out upper and lower tools. Our tools offer solutions to your application cases - even for complex technical ones.

2.Service package

Basic:we offer you rapid troubleshooting through telephone support and costs for on-site missions are reduced.

Special:Engineers available to service machinery overseas for the necessary maintenance.

Partner:Our located dealers or customers who sell or use our machines are fully behind you,they are our friendly partner and supply good advice to you.

3.Technical Service(After-sale service)

Installation and start-up(Available for complex and big machines or if you have demand)

FAQ

If you want to get more information,you can contact me via:

WEB: http://leolivia.en.made-in-china.com